Lens barrel

A lens barrel and lens technology, which is applied to instruments, televisions, installations, etc., can solve problems such as complex structures, staggered positions of frame parts, and lens optical axis deviation, and achieve simple and reliable fixing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

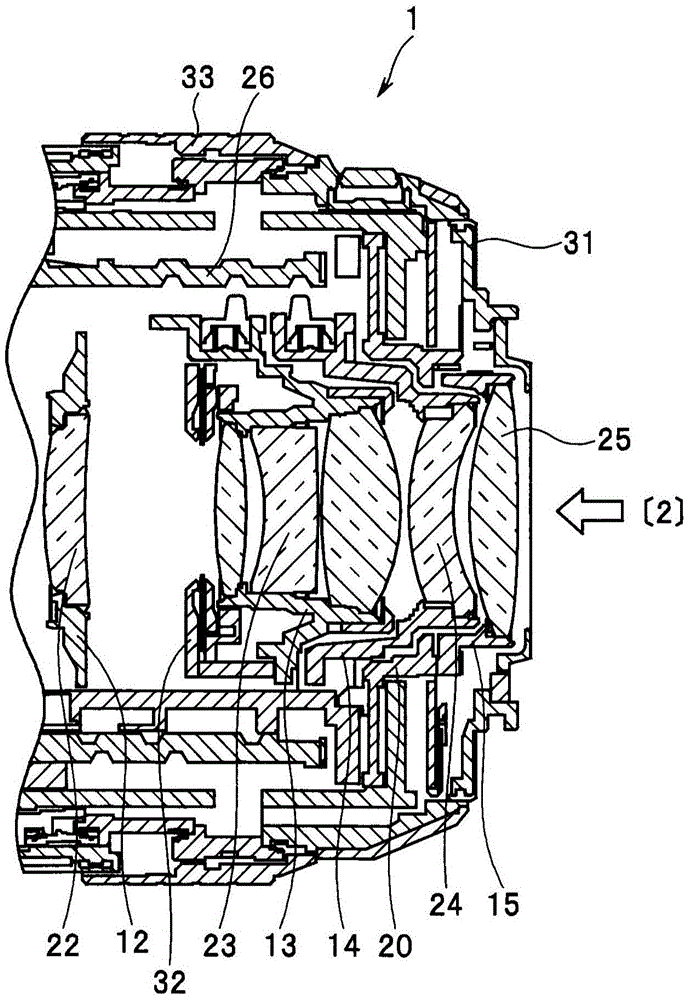

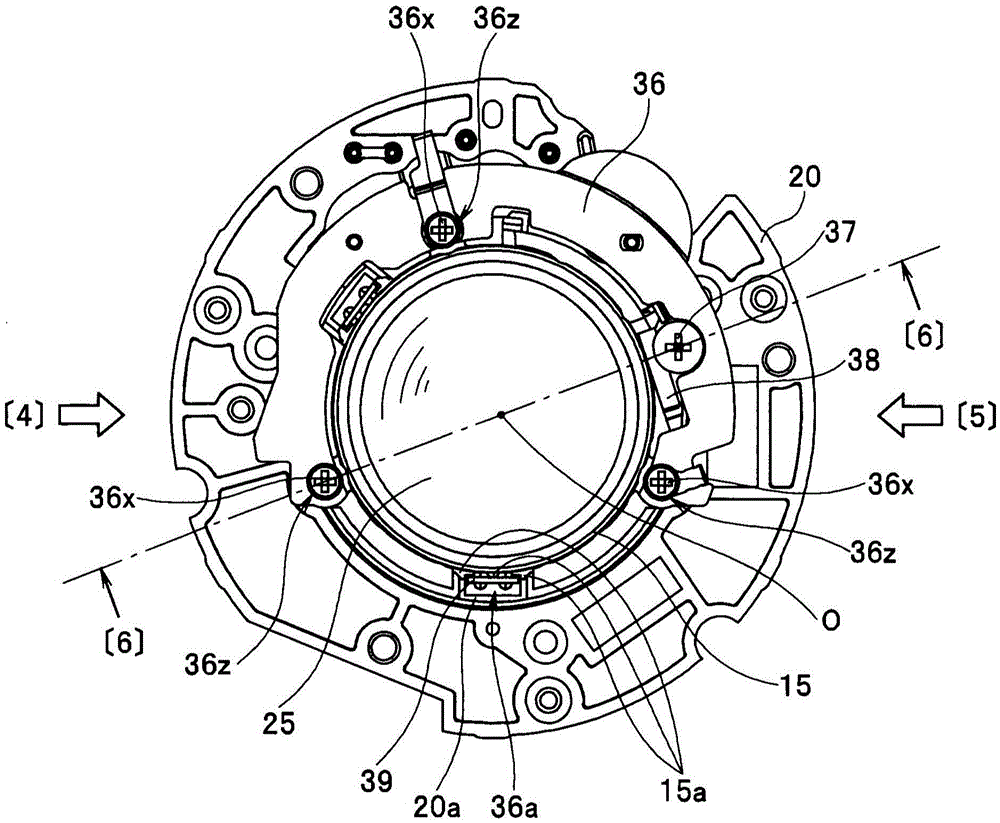

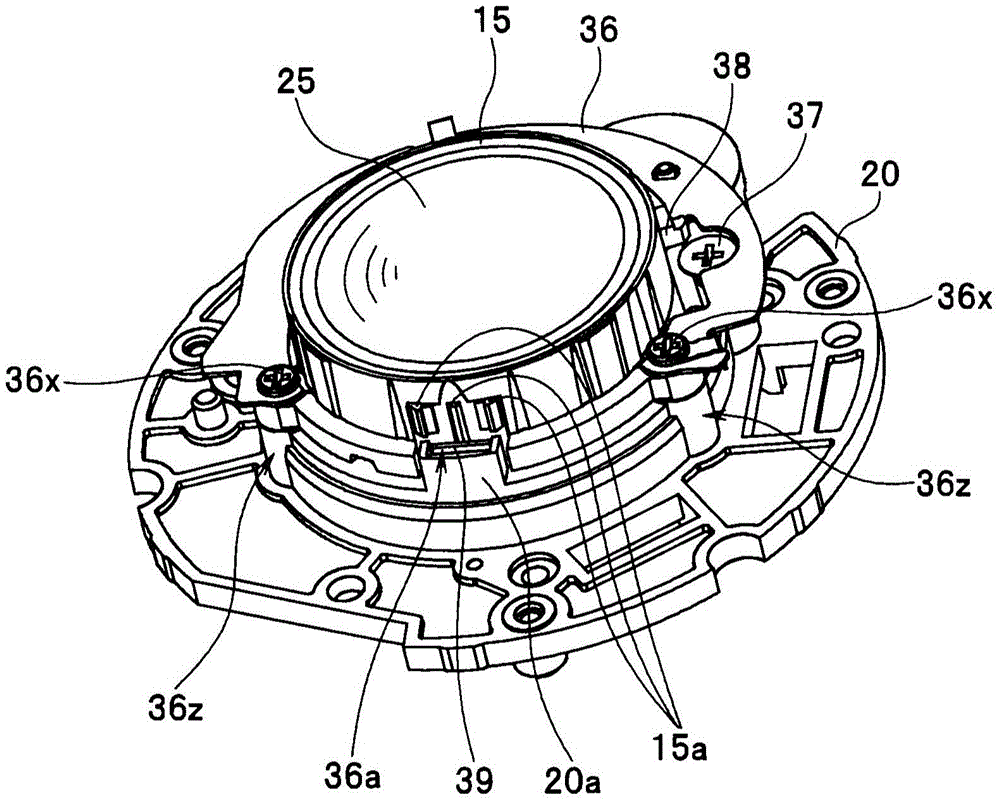

[0019] Hereinafter, the present invention will be described with reference to the illustrated embodiments. One embodiment of the present invention illustrates, for example, a lens barrel used in an imaging device such as a camera (hereinafter simply referred to as a camera) configured to photoelectrically convert an optical image formed by an optical lens using a solid-state imaging device, The image signal thus obtained is converted into digital image data representing a still image or a moving image, the digital data thus generated is recorded in a recording medium, and the still image or moving image is displayed on the basis of the digital image data recorded in the recording medium displayed on the device.

[0020] In addition, in the present embodiment, the optical axis of the imaging optical system in the lens barrel is denoted by a symbol O. And, in the direction along the optical axis O, the side facing the front surface of the lens barrel where the subject exists is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com