Method for Determining Composite Parameters Characterizing Thin Film Adhesion Based on Cohesion Model

A film adhesion and cohesion technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of insufficient reliability margin of measurement results, film damage, etc., to achieve a clear and clear parameter determination process, reduce Work complexity and effect of ensuring reliability margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

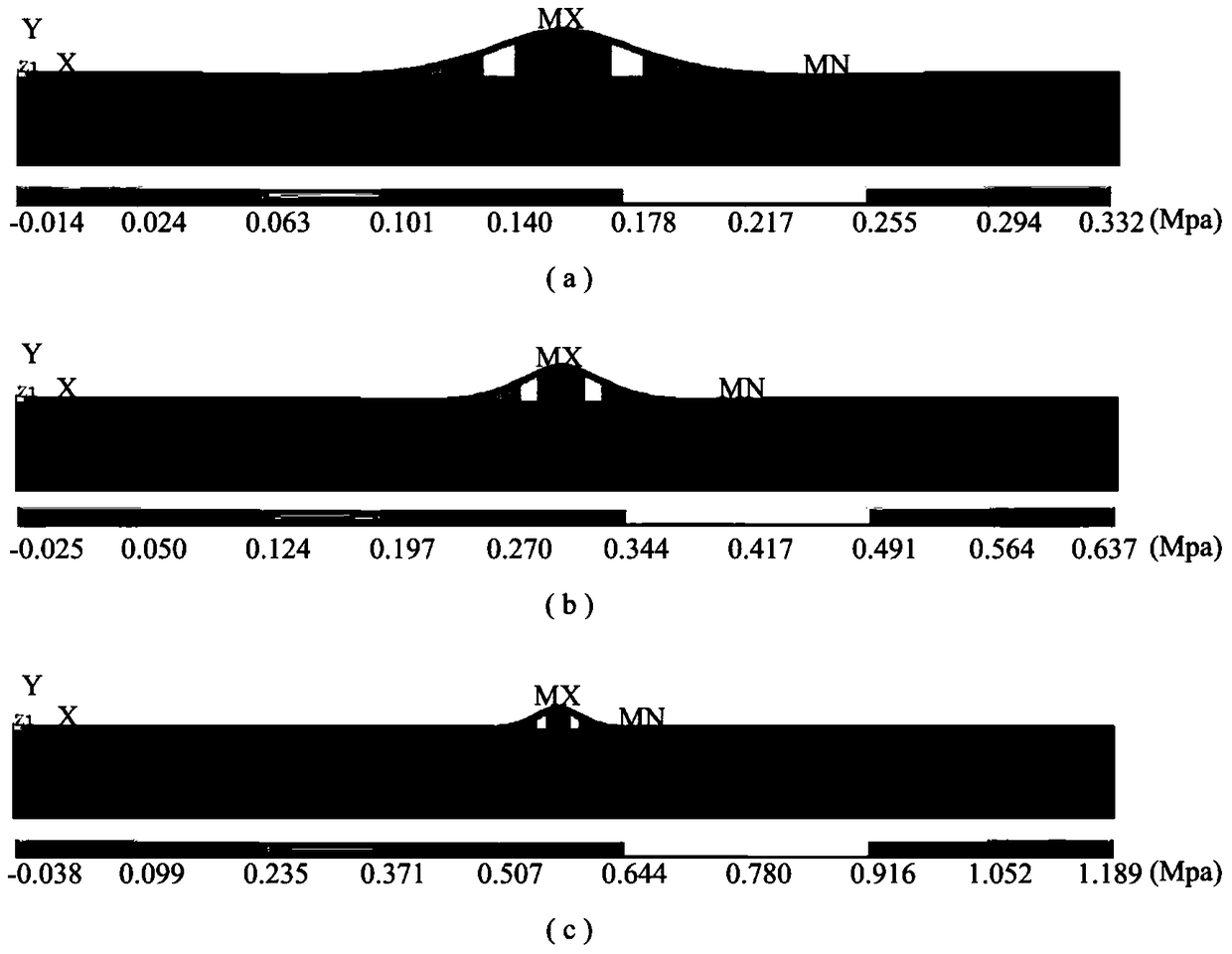

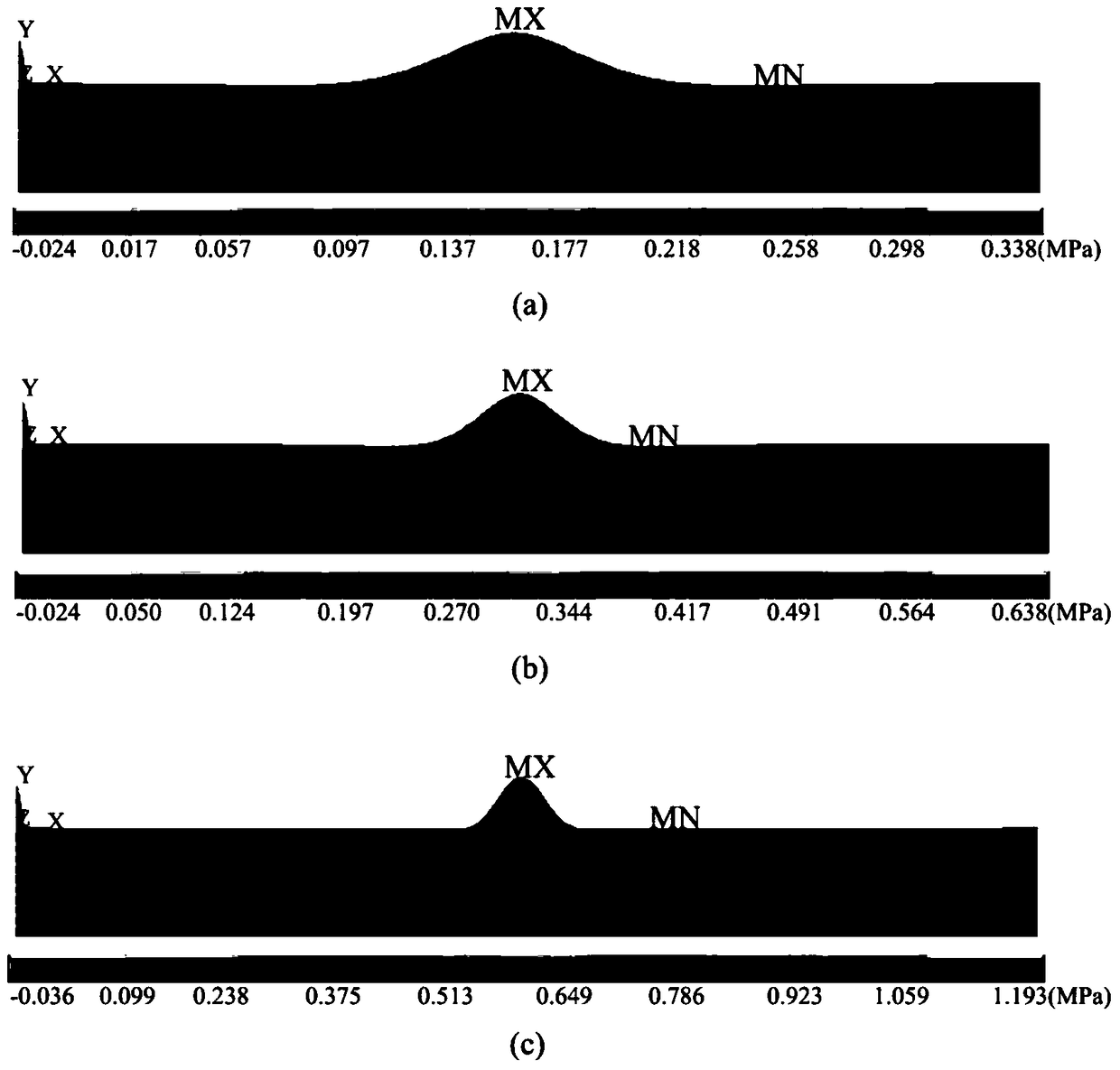

Image

Examples

Embodiment Construction

[0020] The method of the present invention will be described in detail below.

[0021] 1) The adhesion between the film and the substrate can be expressed by the relationship between the adhesion force between the interface and the relative displacement of the interface, and the adhesion force between the interface changes with the relative distance of the material interface, This functional relationship can be described by a cohesion model. The potential function of the exponential cohesion model proposed by Xu and Needleman is used to express this relationship:

[0022]

[0023] Among them, Δ n is the normal interface splitting distance, Δ t is the splitting distance of the tangential interface, σ max is the maximum stress normal to the interface, δ n is the normal characteristic length, corresponding to the maximum value of the normal interface stress σ max The splitting distance of the time interface, is the tangential characteristic length, corresponding to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com