Sheet for forming resin film

A resin film and sheet technology, applied in the direction of synthetic resin layered products, film/sheet adhesives, applications, etc., can solve the problems of reduced product yield, insufficient thickness precision of protective film, etc., to prevent curling scar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, the details of the sheet for resin film formation of this invention are demonstrated.

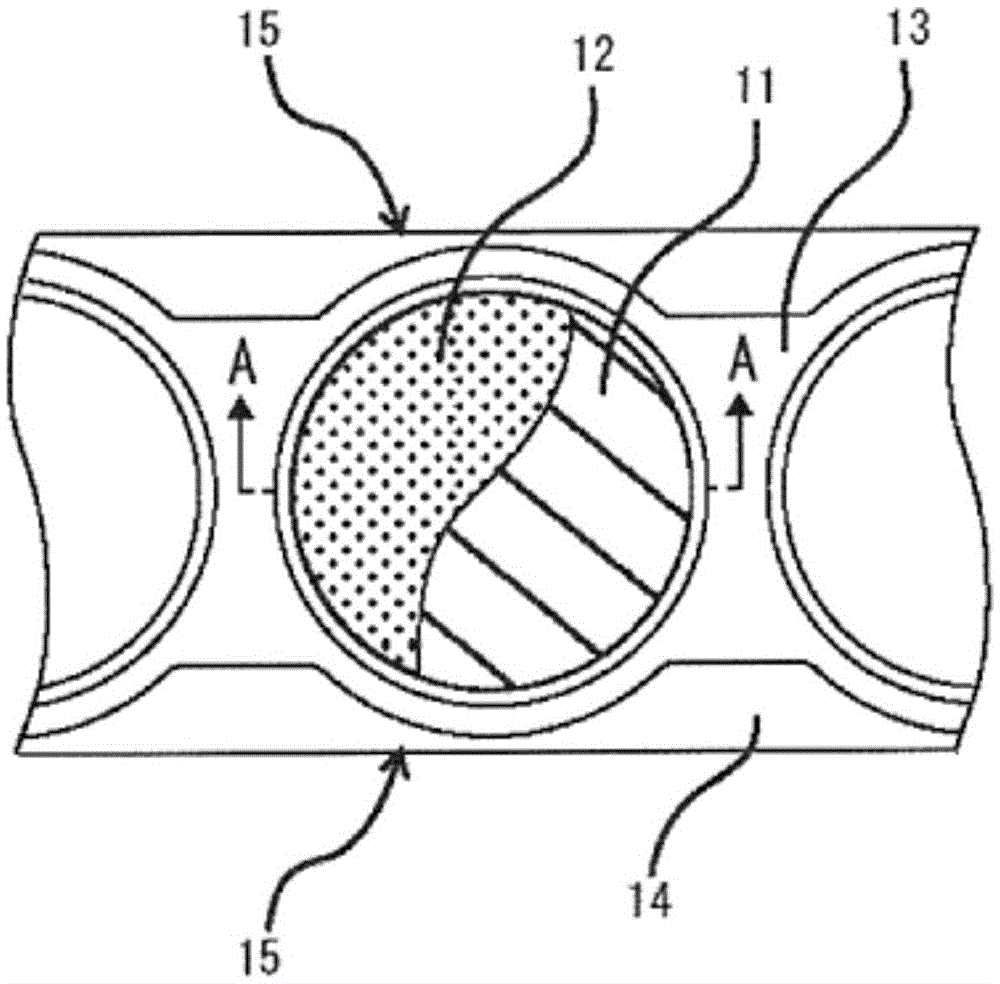

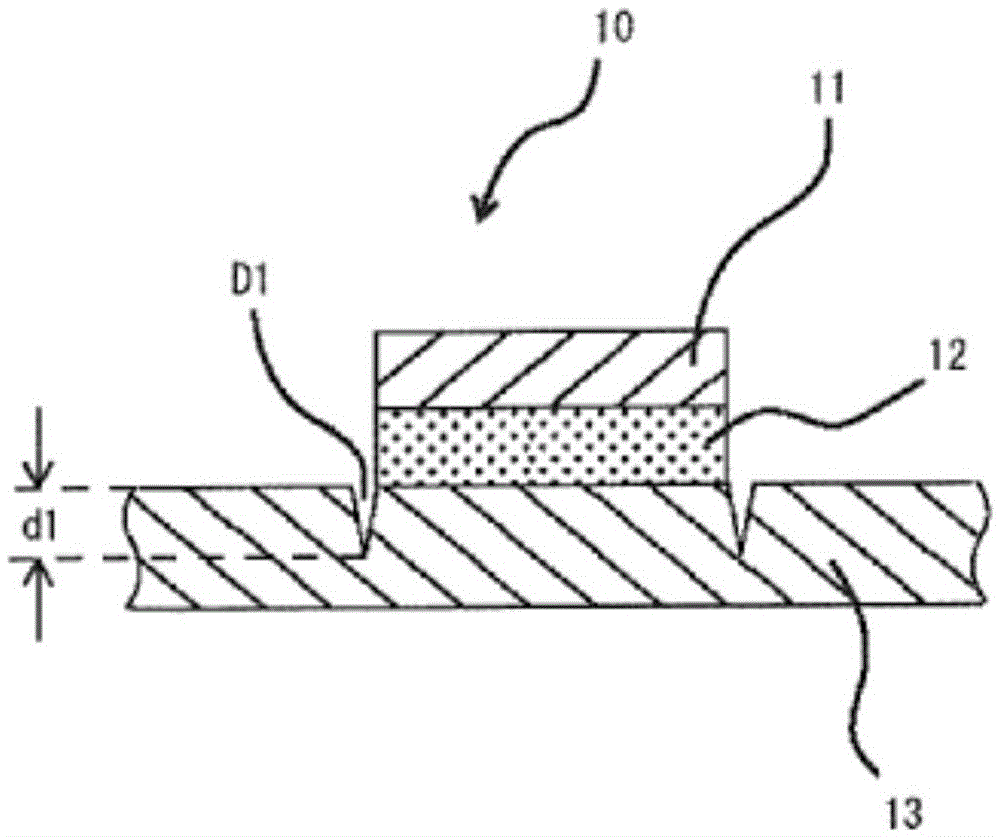

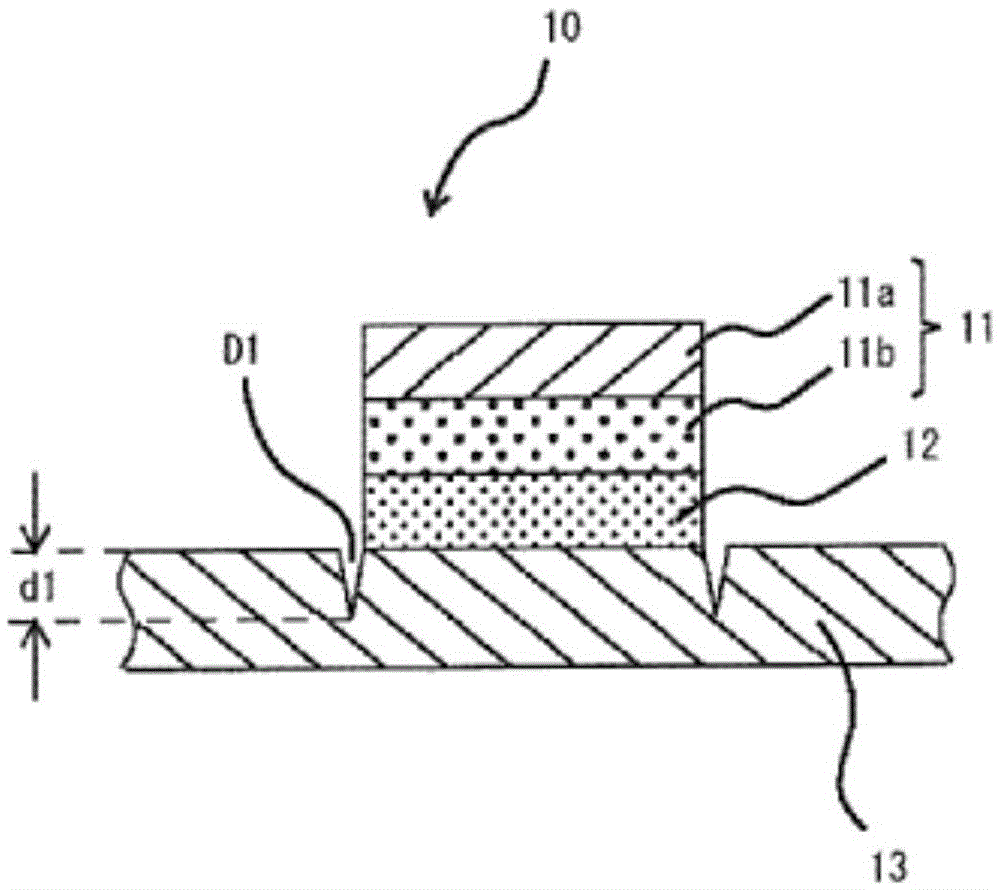

[0039] figure 1 It is a plan view showing the first embodiment of the resin film forming sheet 10 of the present invention, figure 2 for will figure 1 The shown resin film forming sheet 10 is a schematic cross-sectional view when cut along the line A-A. Such as figure 1 and figure 2 As shown, the sheet 10 for resin film formation of this invention has the structure which laminated|stacked the support sheet 11, the resin film formation layer 12, and the peeling film 13 in this order.

[0040] In addition, the support sheet 11 and the resin film forming layer 12 are cut into a desired planar shape and partially laminated on the release film 13 . Here, the desired planar shape of the laminate composed of the support sheet 11 and the resin film forming layer 12 is not particularly limited as long as the laminate is partially laminated on the release film 13. It is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com