a jet machine

A sprayer and sprayer technology, applied in the field of sprayers, can solve the problem that the degree of atomization depends on performance and arrangement, and high energy consumption, and achieve the effect of reducing water pressure and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

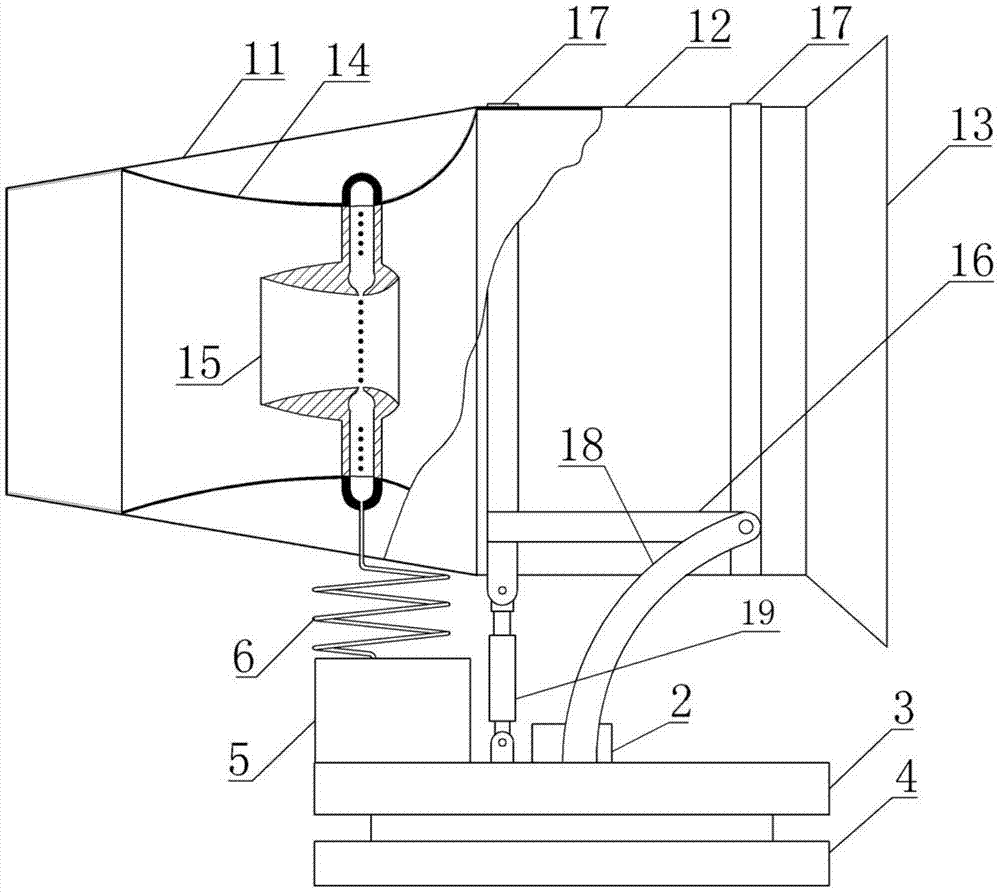

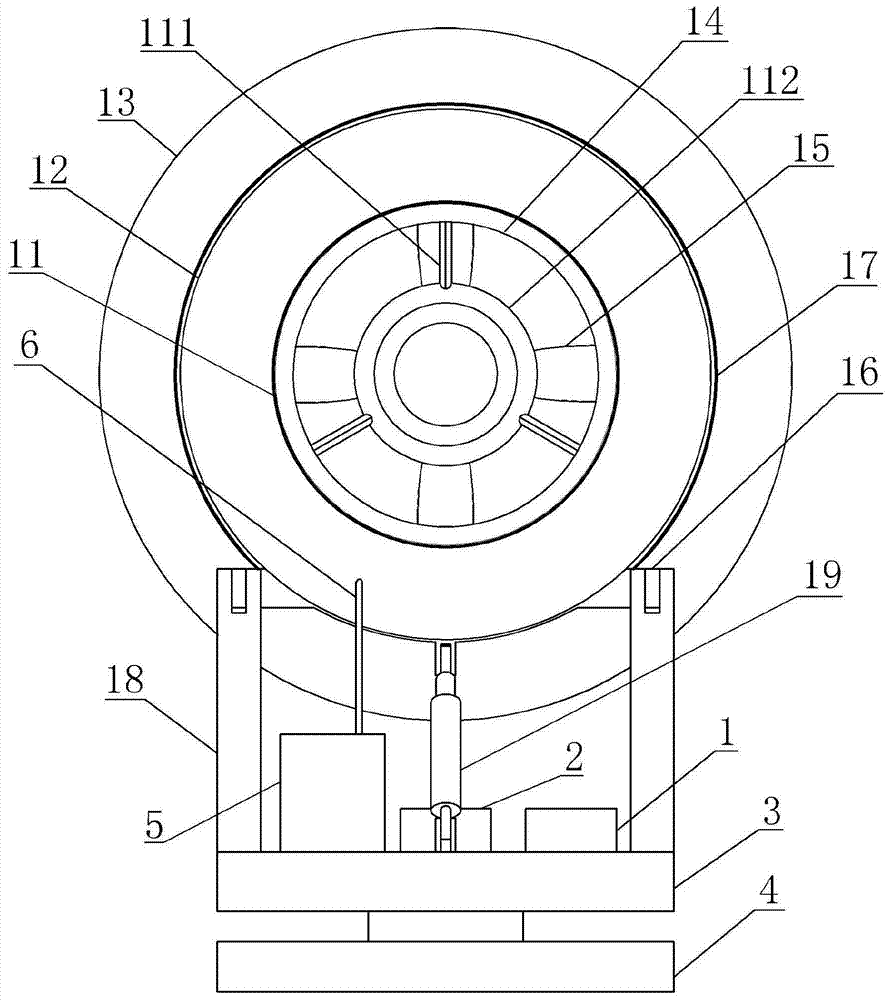

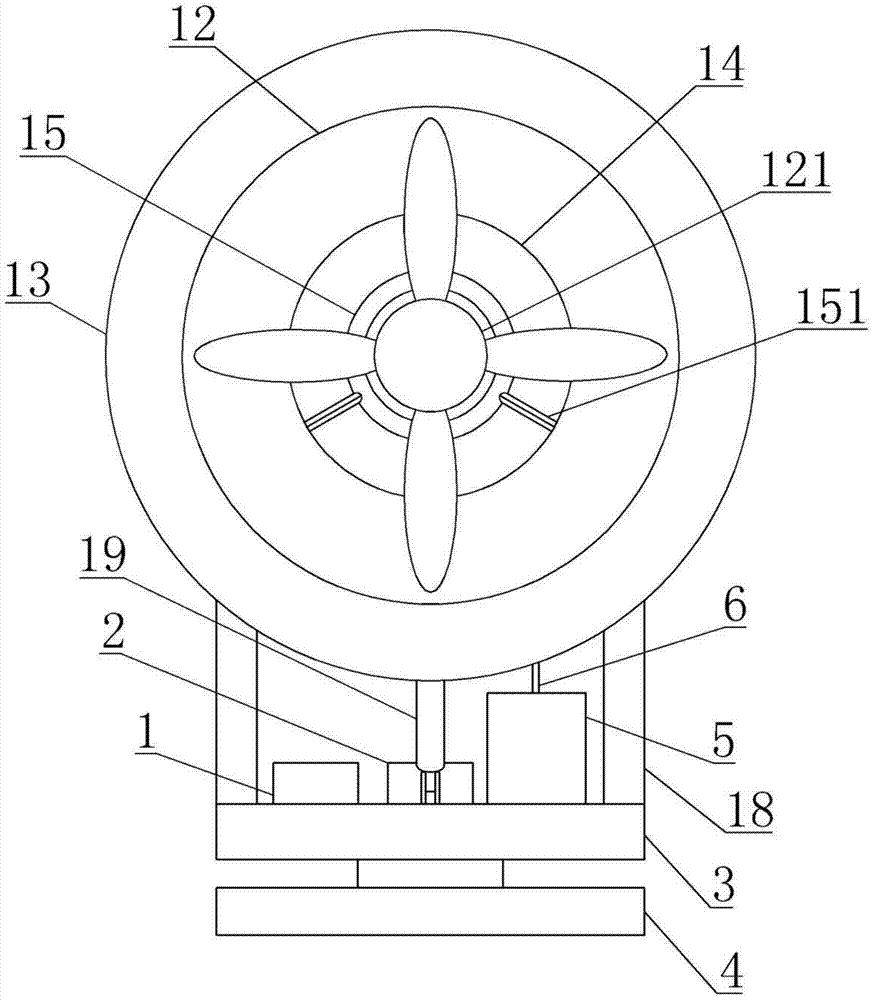

[0020] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a jetting machine is mainly composed of a jetting device, a supporting device, a controller 1, a rotating mechanism 2, a platform 3, a base 4, a water pump 5, and a water delivery pipe 6. Described water pump 5 is auxiliary equipment, and its main function is to guarantee water supply to water supply pipe 6.

[0021] The two ends of the injection device are open, mainly composed of a hollow nozzle 11, a pressurized chamber 12 and a shroud 13 connected in series. The nozzle 11 is provided with a first throat 14, and the first throat is provided with a second throat. 15. The first throat pipe 14 and the second throat pipe 15 are connected through a support frame 151; the nozzle 11, the first throat pipe 14, and the second throat pipe 15 are coaxial.

[0022] Such as Figure 5 and Figure 6 As shown, the cross-section of the first throat is a hyperbolic structure with a small middle and large ends, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com