Execution method of plate spraying process adopting protruding strip guide groove for guiding and adopting sound isolation box for noise reduction

An implementation method and soundproof sound box technology, applied in coatings, devices for coating liquid on the surface, etc., can solve problems such as complex mechanical structures and control structures, increased costs, reduced equipment maintainability, and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

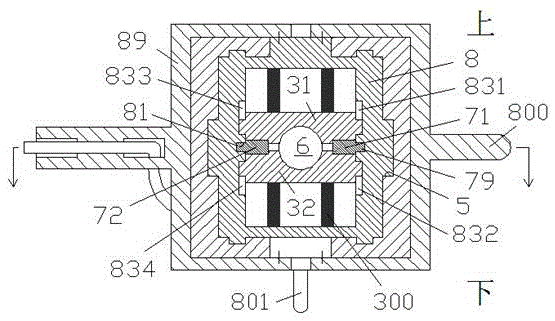

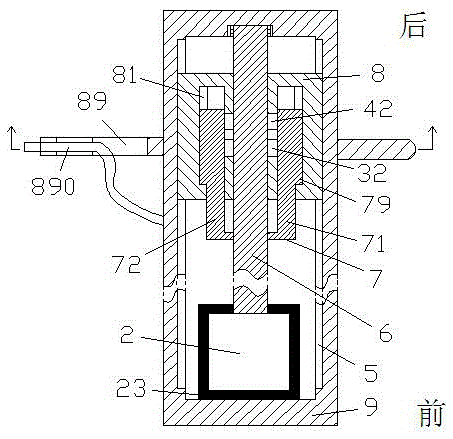

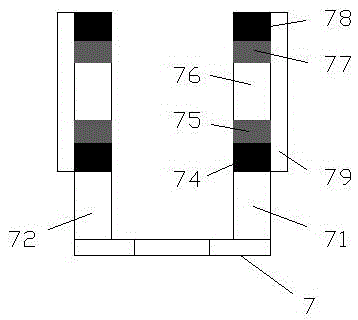

[0012] Combine below Figure 1-4 The present invention will be described in detail.

[0013] According to an embodiment, an execution method of a plate spraying process guided by a raised strip guide groove and noise-reducing with a soundproof box uses a plate spraying device, which is used to drive the spraying nozzle 890 to move during the spraying process, It also includes: a support frame 9, a walking bracket 8, and a nozzle bearing part 89 fixed from the upper and lower sides of the walking bracket 8 and used to clamp a spray nozzle 890 for spraying, wherein it is driven by a motor 2 and is rotatably installed on the The screw rod 6 extending back and forth on the support frame 9 passes through the walking bracket 8, and the walking bracket 8 can move forward and backward under the guidance of the guide rail groove 5 extending back and forth in the support frame 9, and the motor 2 is provided with a soundproof box 23 fixedly connected with the support frame 9, the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com