Special gear case for labor-saving bicycle and gear transmission mechanism in gear case

A technology of gear transmission mechanism and gearbox, which is applied in the direction of wheel transmission, vehicle gearbox, vehicle parts, etc., and can solve problems such as riding effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

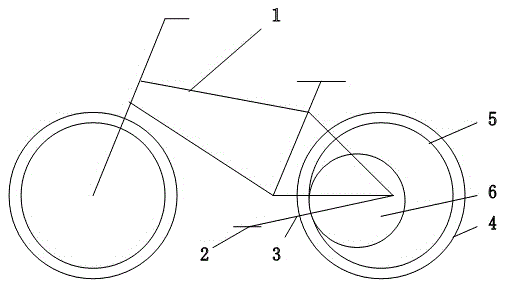

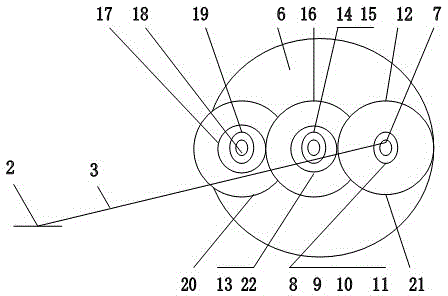

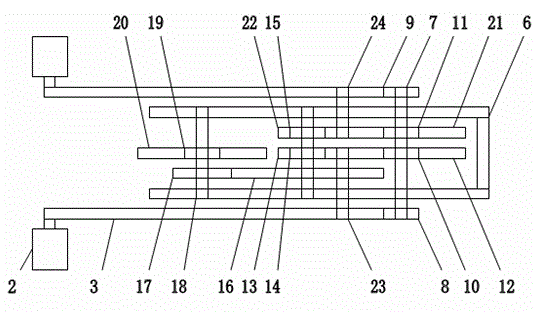

[0007] figure 1 figure 2 image 3 Among them, a special gearbox 6 for a labor-saving bicycle and the gear transmission mechanism in the gearbox include a bicycle 1. A pair of pedals 2 that move up and down are arranged on the left and right sides of the frame, and a gear box 6 is installed in the rear wheel 4 of the bicycle. Connect input shaft 7. : The input shaft 7 that the ball bearing 8 is connected is a fulcrum that does not rotate. The two input bull gears 12, 21 are in turn connected to the input shaft 7 via ball bearings 10, 11. The left and right long arms 3 are fixed with linkage rods 23, 24 near the input shaft 7 ball bearings 8, 9, which are respectively connected to the outer contour edges of the input bull gear 12, 21. It is characterized in that: when the cyclist pedals the left pedal 2, the long arm 3 directly drives the input large gear 12 to rotate counterclockwise in one direction through the linkage rod 23, and the torque force input to the large gear...

Embodiment 2

[0009] figure 1 Figure 4 Figure 5 A special gear box 6 for a labor-saving bicycle and a gear transmission mechanism in the gear box, including a bicycle 1. A pair of pedals 2 that move up and down are arranged on the left and right sides of the frame, and a gear box 6 is installed in the rear wheel 4 of the bicycle. , Bearings 25, 26 are connected to the input shaft 7. The input shaft 7 that unidirectional ratchet, bearing 25,26 are connected is unidirectional, and the large torque force rotates. A single input bull gear 27 is directly connected to the input shaft 7 . When the cyclist pedals the left pedal 2, the long arm 3 directly drives the input large gear 27 through the one-way ratchet, the bearing 25 and the input shaft 7 to rotate counterclockwise in one direction, and the torque of the input large gear 27 is also in the long arm 3 ( Leverage), under the action of is directly magnified several times. The single input bull gear 27 meshes with the single pinion 28...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com