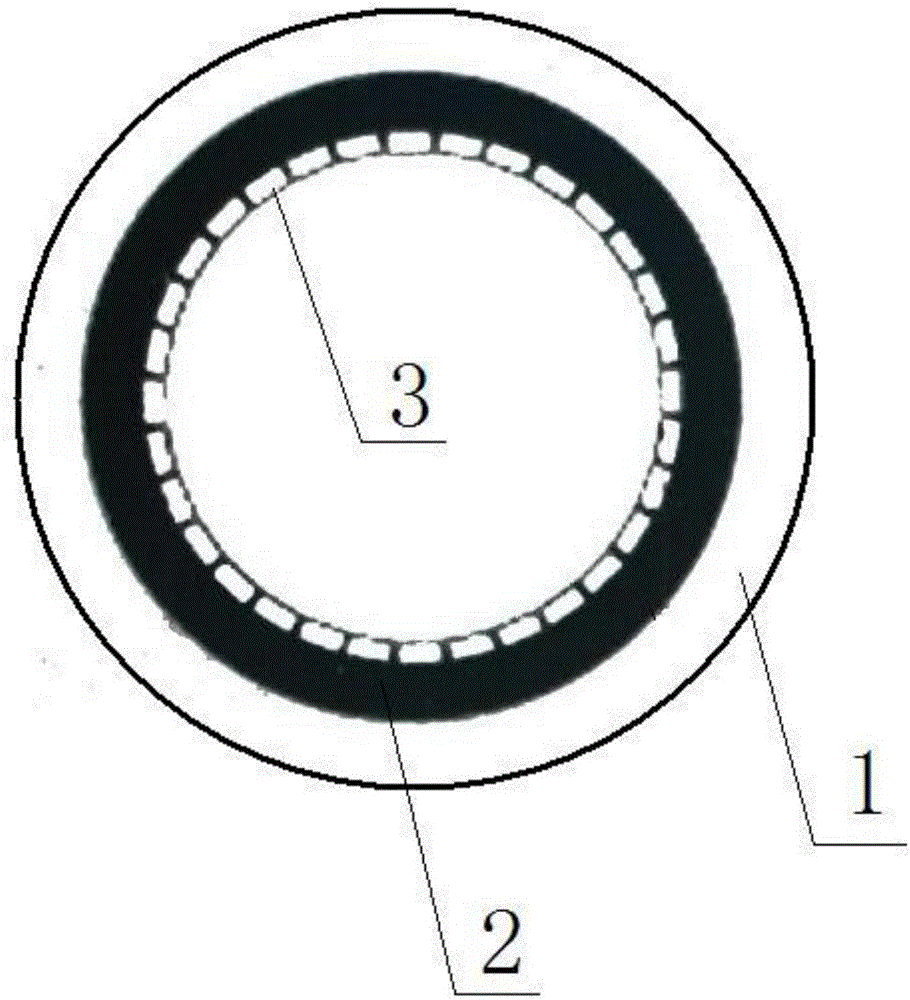

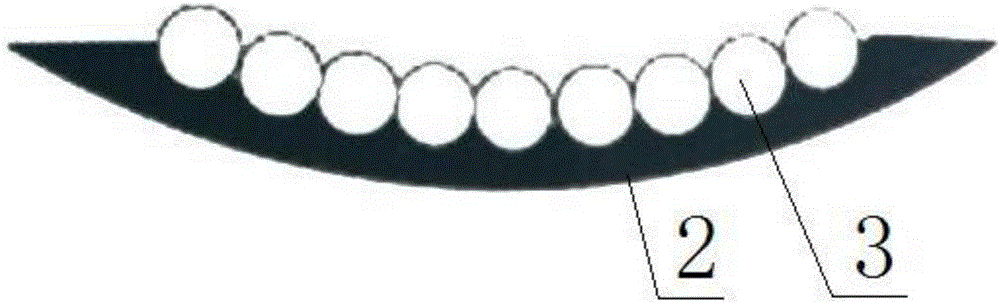

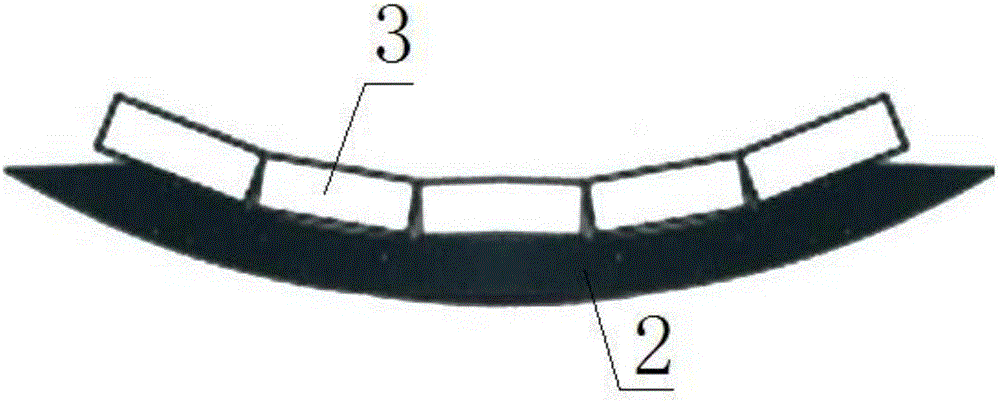

Pipeline for desulfuration

A technology of pipes and steel pipes, which is applied in the field of environmental protection equipment in power plants, can solve the problems of poor stickiness of desulfurization pipes, achieve the effect of tight combination, not easy to fall off, and solve the effect of non-abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: The preparation scheme is the above method, and its semi-finished rubber formula is 95 parts of natural rubber, 0.8 part of stearic acid, 45 parts of calcium carbonate, 8 parts of EPDM rubber, 0.8 part of accelerator MBTS, and 0.8 part of antioxidant RD0. 8 parts, sulfur 2.5 parts, zinc oxide 4 parts.

Embodiment 2

[0035] Embodiment 2: The preparation scheme is the above method, and its semi-finished rubber formula is 105 parts of natural rubber, 1 part of stearic acid, 55 parts of calcium carbonate, 12 parts of EPDM rubber, 1.2 parts of accelerator MBTS, and 1.2 parts of antioxidant RD1. 2 parts, sulfur 35 parts, zinc oxide 6 parts.

Embodiment 3

[0036] Embodiment 3: the preparation scheme is the above method, and its semi-finished rubber formula is natural rubber: 100 parts, 1 part of stearic acid, 52 parts of calcium carbonate, 11 parts of EPDM rubber, 1 part of accelerator MBTS, 1 part of antioxidant RD, 3 parts sulfur, 5 parts zinc oxide

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap