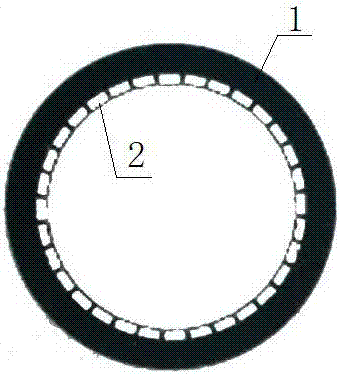

A ceramic wear-resistant rubber tube and its manufacturing method

A wear-resistant rubber tube and a manufacturing method technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of inconvenient installation, falling off in pieces, poor metal deformation and deformation ability, etc. The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of wear-resistant ceramic rubber, comprising the following steps:

[0046] The wear-resistant ceramic block was put into acetone solution for degreasing treatment,

[0047] Put the acetone-soaked and dried porcelain block into the mixed solution of carbon tetrachloride and chromic acid for oxidation treatment, take it out after soaking, and dry it. The drying temperature is generally 100 degrees;

[0048] Coat the treated porcelain block with Chemlok 607 first, then apply 220 adhesive once after drying, and then dry it;

[0049] Coat the rubber with Chemlock 205, stick it together with the arranged ceramic body, and then put the bonded ceramic rubber into a vulcanization tank for vulcanization and molding. The above wear-resistant ceramic block is alumina ceramic.

[0050] The ceramic blocks produced by this process are tightly combined with rubber and are not easy to fall off.

[0051] The specific formula of preferred rubber is 80 parts of natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap