Oiling Mechanism of Axle Tube Flange for Automobile

A technology of oil injection mechanism and shaft tube, which is applied in the direction of mechanical equipment, vehicle parts, engine components, etc., can solve the problems of unsmooth design oil injection process, lubricating oil backflow, insufficient lubrication, etc., achieve good maneuverability, prevent backflow, and oil injection smooth process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

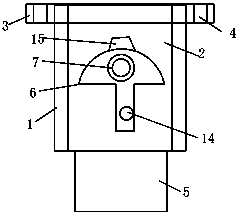

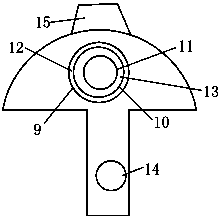

[0011] Combine below figure 1 with figure 2 Specific description embodiment:

[0012] The axle tube flange for automobiles, the axle tube flange for automobiles includes a shaft body 1, a flange hole 2 is opened in the middle of the shaft body 1, and a flange hole 2 is opened at the upper edge of the shaft body 1. Several protrusions 3 are provided with fixed threaded holes 4; the bottom of the shaft body 1 is provided with a connecting pipe fitting 5 that can be connected with the hollow circular shaft tube; the outer wall of the shaft body 1 An oil injection mechanism 6 is provided, and the oil injection mechanism 6 is recessed on the outer wall of the shaft body 1 in an umbrella-shaped structure; an oil injection hole 7 is opened on the upper part of the oil injection mechanism 6, and the oil injection hole 7 communicates with the flange hole 2, and the oil injection The hole 7 is a three-stage depression mechanism. The three-stage depression mechanism 8 is respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com