A non-destructive testing device and method for elevator traction steel belt

An elevator traction and non-destructive testing technology, applied in the direction of material magnetic variables, can solve the problems of poor anti-interference ability, low detection accuracy, poor accuracy, etc., to avoid missed detection, improve detection accuracy, and solve the effect of low detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

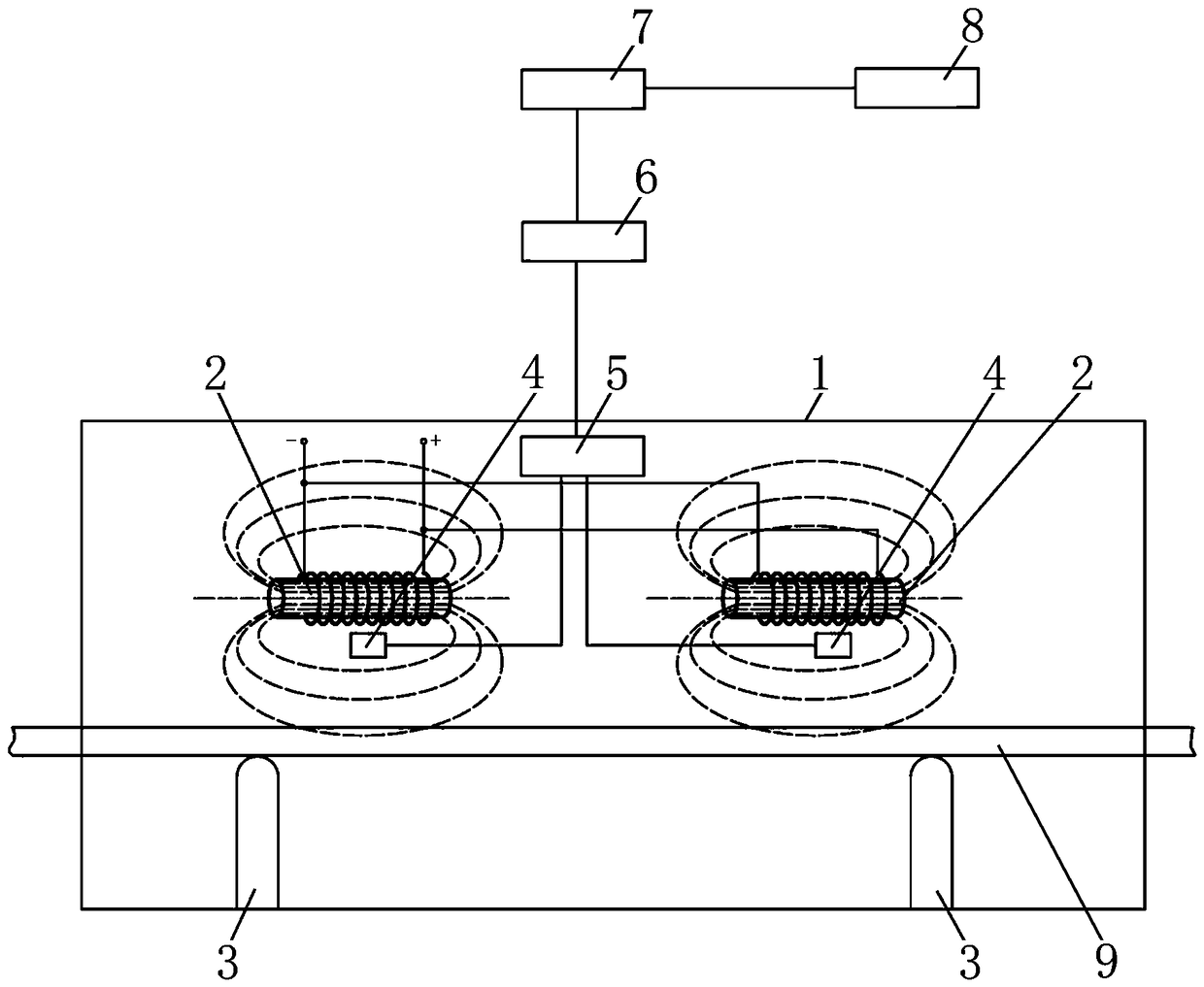

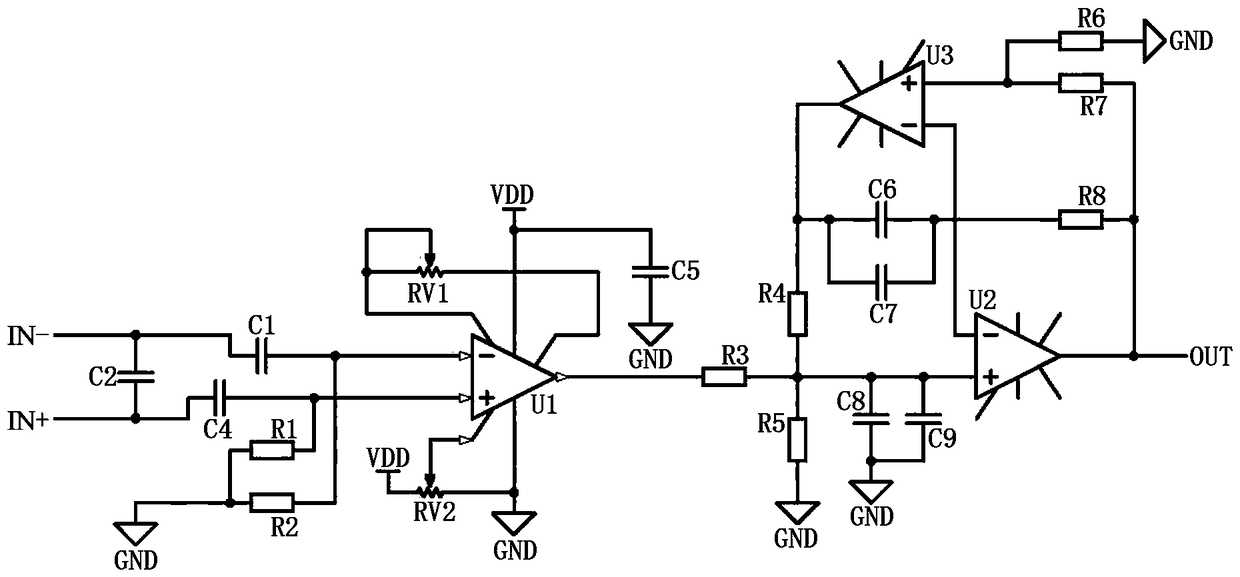

[0020] A non-destructive testing device for elevator traction steel strips, comprising a shielding case 1, a reference magnetic field source 2, a magnetic field sensor 4, a differential amplifier circuit 5, a filter circuit 6, a signal transmission module 7, and a computer 8;

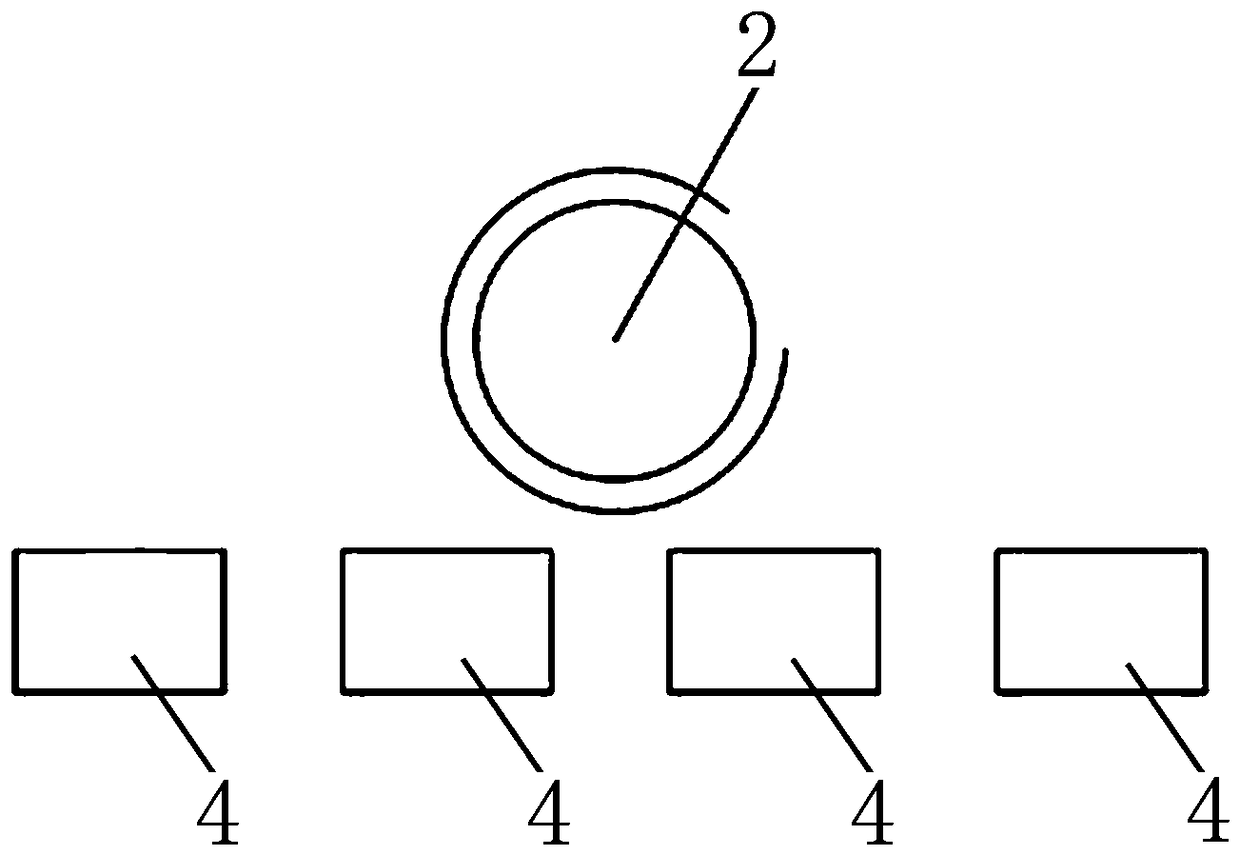

[0021] Wherein, the left side and the right side of the shielding shell 1 are respectively provided with a detection hole through the inside and outside, and the two detection holes are opposite to each other; the number of reference magnetic field sources 2 is two; the two reference magnetic field sources 2 are respectively Installed in the left part of the inner cavity and the right part of the inner cavity of the shielding shell 1, and the magnetic field strengths and directions of the two reference magnetic field sources 2 are equal; the number of magnetic field sensors 4 is two groups; each group of magnetic field sensors 4 includes N magnetic field sensors arranged densely and equidistantly from fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com