Pneumatic pipeline conveying system and method

A transmission system and pneumatic pipeline technology, which is applied in the field of pipeline transmission system, can solve the problems of complicated structure setting and control, easy to fail, etc., and achieve the effects of simple structure, reduced failure rate and simple system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] like figure 2 As shown in the figure, the pneumatic pipeline transmission system of the present invention includes a horizontally arranged transmission pipeline 3, a sending station 2 and a receiving station 4 are arranged on the transmission pipeline 3, and a conveyor inlet is arranged at the sending station 2, A transmitter outlet is provided at the receiving workstation 4, and a door is provided at the transmitter inlet and the transmitter outlet;

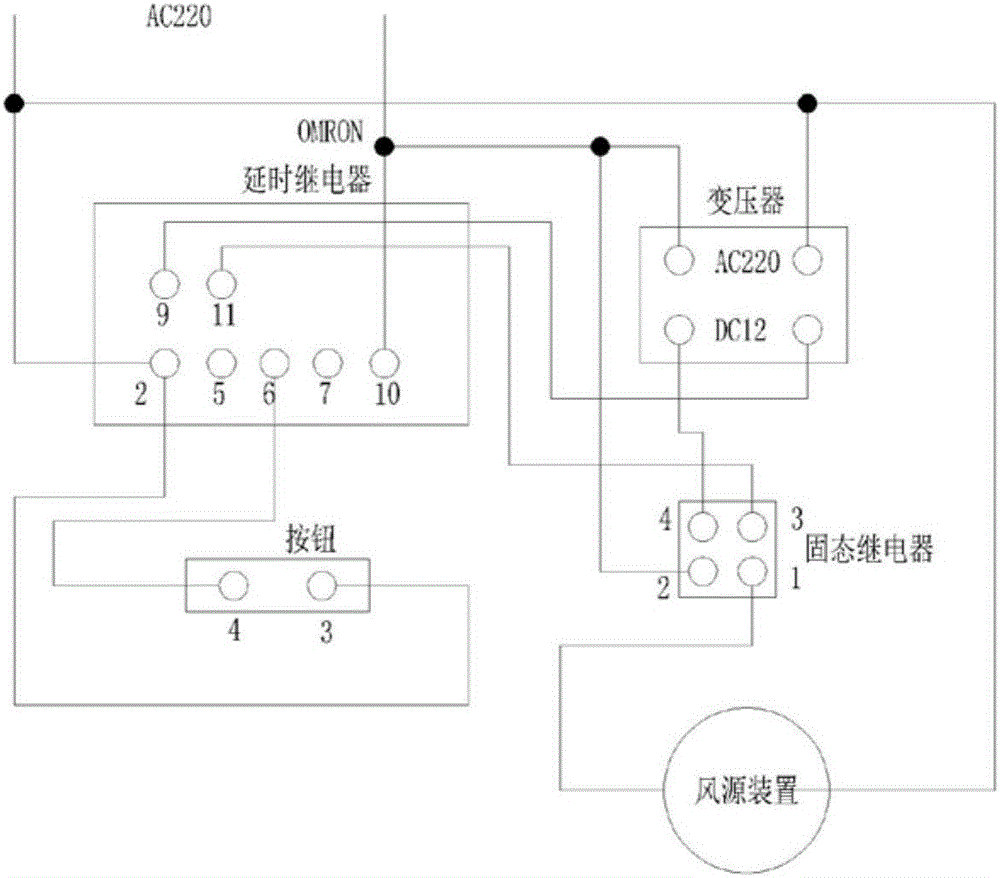

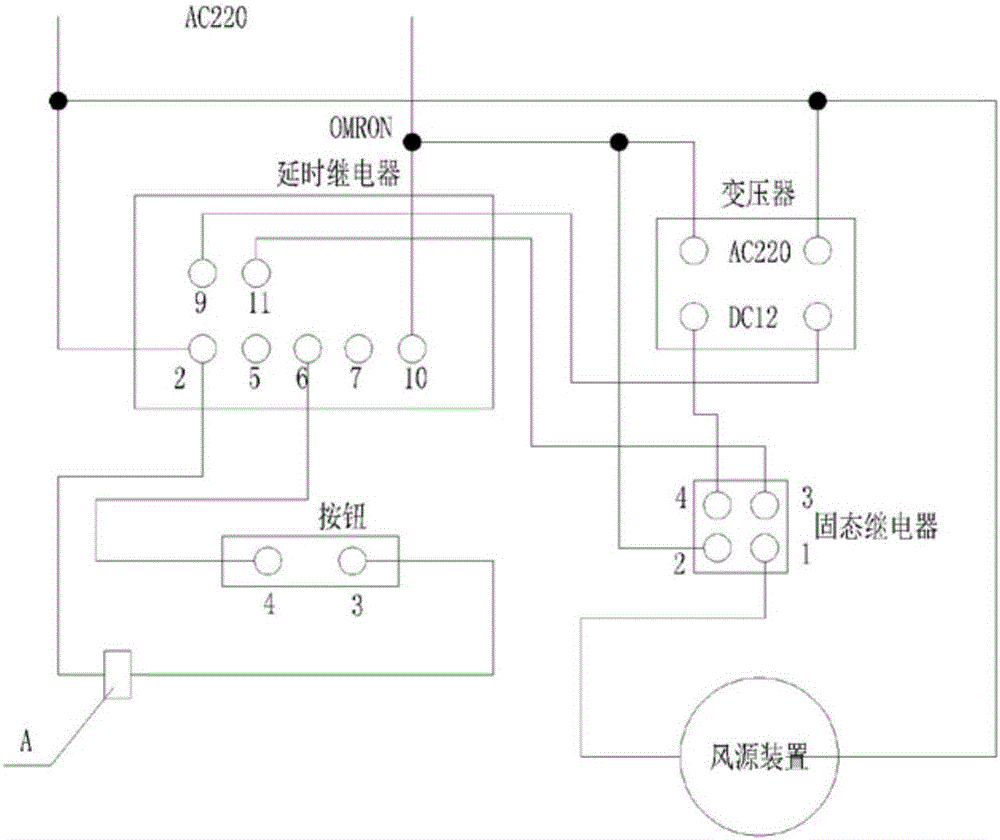

[0079] At the sending station 2, an air intake pipeline 10 is connected through the connection part 1, and the air intake pipeline 10 is connected with the air source device 8 through the connection part 9;

[0080] The end of the transmission pipeline 3 is connected with an air extraction pipeline 6, and the air extraction pipeline 6 is connected with the air source device 8;

[0081] The transmitter 11 is put into the transmission pipeline 3 from the inlet of the transmitter, and the air source device 8 connected with...

Embodiment 2

[0094] like Image 6 As shown, the pneumatic pipeline transmission system of this embodiment includes a transmission pipeline 3, and the transmission pipeline 3 includes at least two vertical pipeline parts 13 and an arc connected with the at least two vertical pipeline parts 13 Pipe section 13'.

[0095] A sending station 2 and a receiving station 4 are arranged at the lower end of the vertical pipeline part 13; a transmitter inlet is arranged at the sending station 2, a transmitter outlet is arranged at the receiving station 4, Doors are provided at the inlet of the transmitter and the outlet of the transmitter;

[0096] The sending station 2 is connected to the air intake pipeline 10 through the positive pressure air source port 1, and the air intake pipeline 10 is connected to the air source device 8 through the connection part 9;

[0097] At a position on the transmission pipeline 3 close to the receiving station 4 , that is, on the connecting bend between the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com