A self-propelled self-releasing type cable rolling vehicle

A cable and rolling technology, applied in the field of electric power, can solve the problems of low degree of automation, time-consuming and labor-intensive transportation of wire reels to the wiring site, etc., and achieve the effect of improving work efficiency and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in detail below.

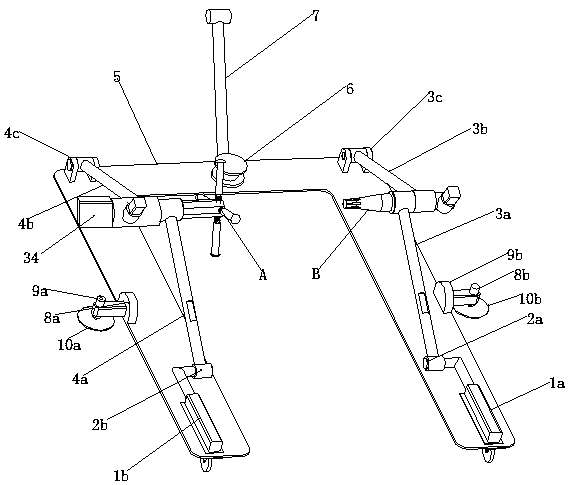

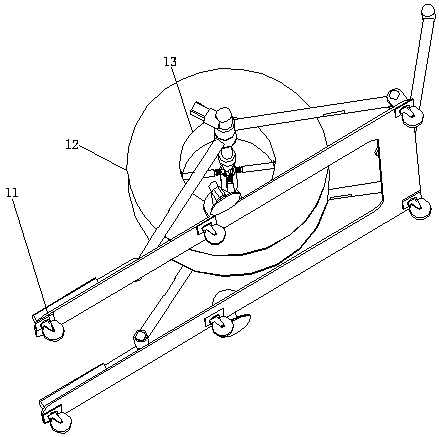

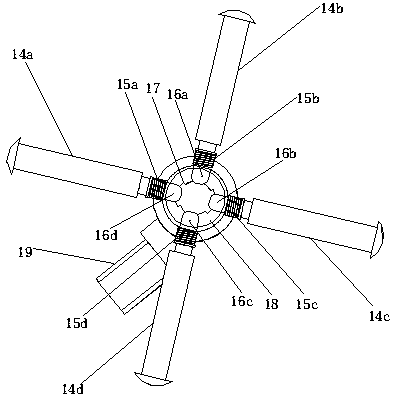

[0014] As shown in the accompanying drawings, a self-propelled self-releasing cable rolling vehicle is characterized in that it includes a roller lifting mechanism, a split shaft and a telescopic cylinder mechanism; the roller lifting mechanism mainly includes the first lifting The hydraulic cylinder 1a and the second lifting hydraulic cylinder 1b are fixed on both ends of the U-shaped car body 5, and are connected with the first active ejector rod 3a and the second active ejector rod through the first rotary joint 2a and the second rotary joint 2b. 4a, the active push rod is installed on the installation cylinder 29 and can rotate around the installation cylinder, while the first driven push rod 3b and the second driven push rod 4b are also installed on the installation cylinder 29 and To achieve linkage, the other end of the driven push rod is installed in the first f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com