A sensing device for testing the weight of contents in a washing bucket of a washing machine

A sensor device, washing machine technology, applied in washing devices, other washing machines, textiles and papermaking, etc., can solve the problems of large installation space and easy collision, to ensure test accuracy and reliability, avoid The effect of vibration, collision and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

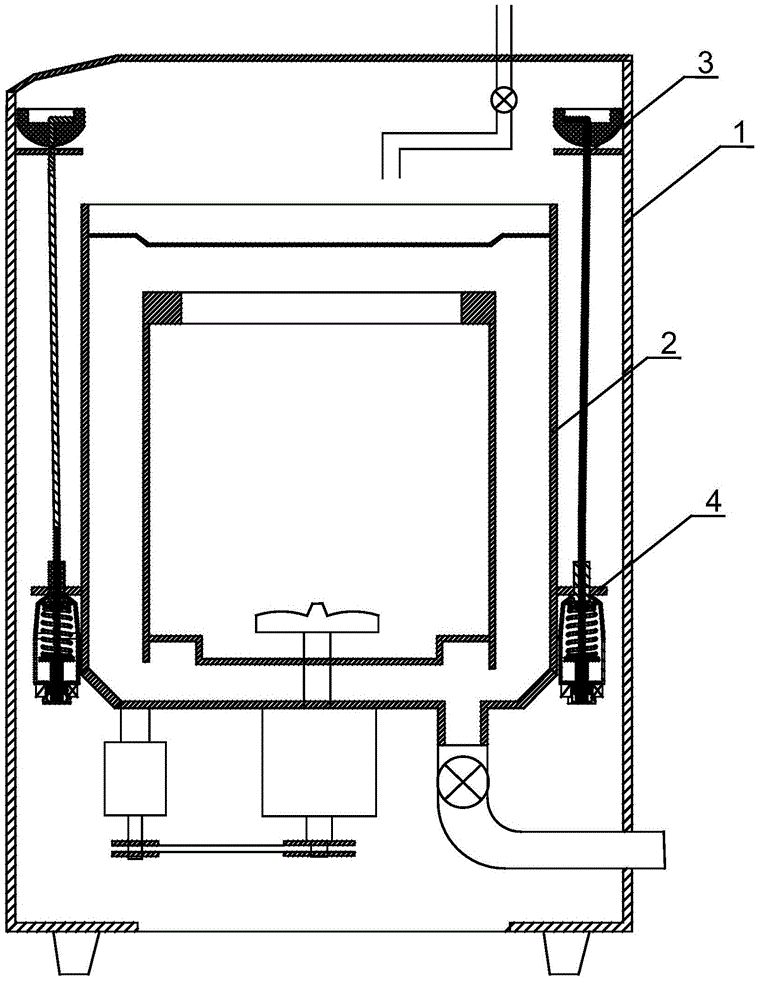

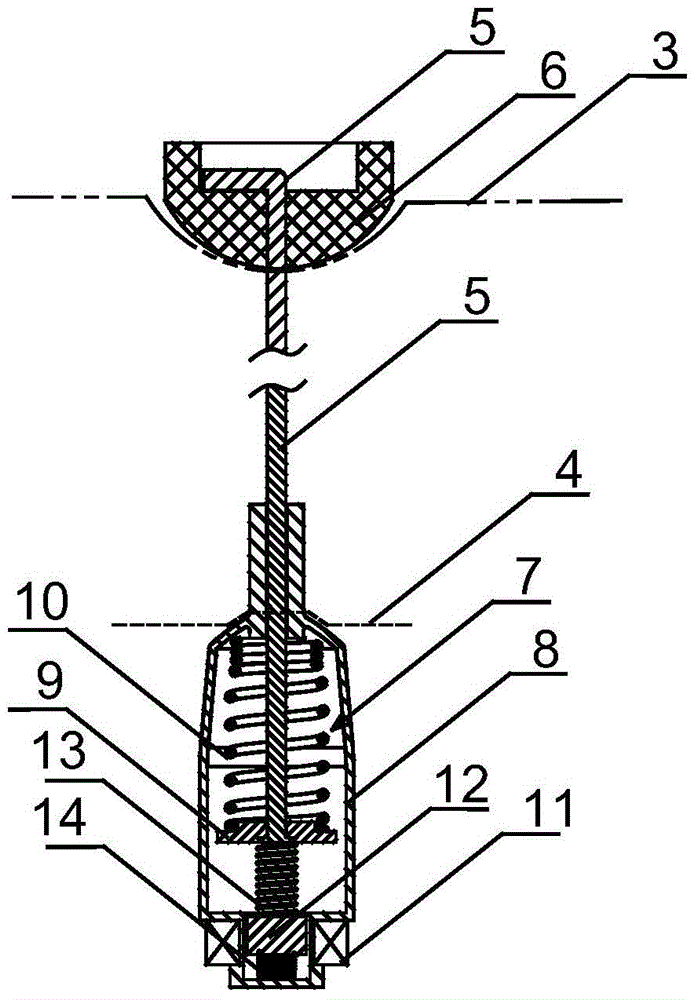

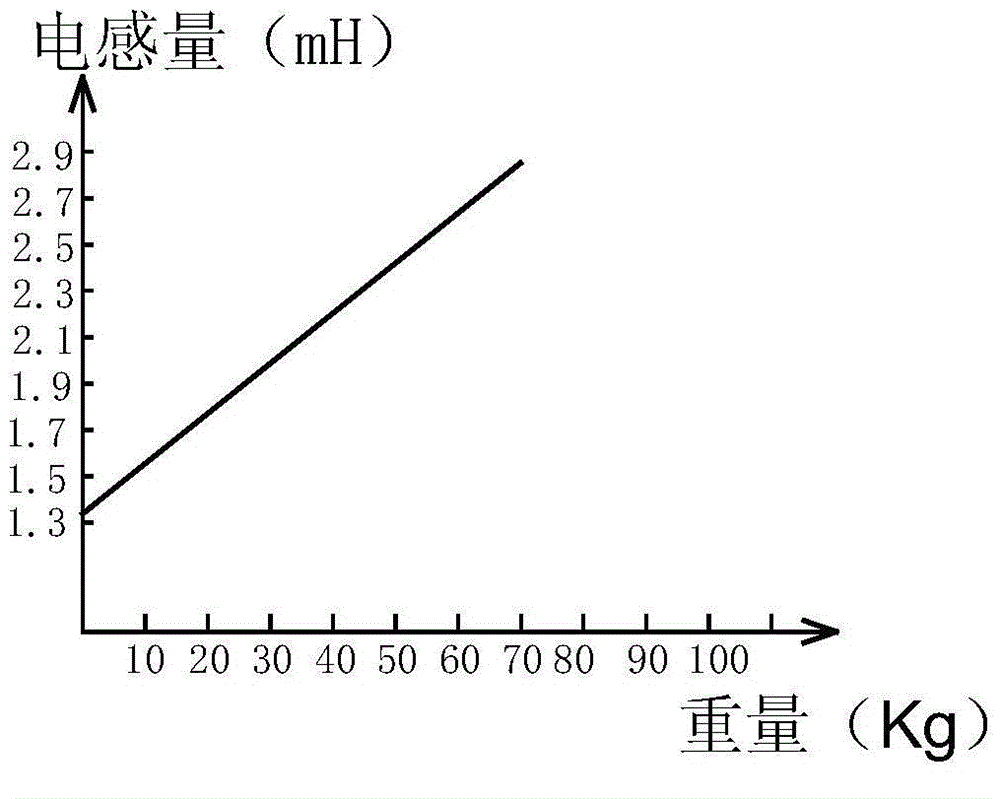

[0018] The sensing device of the present invention, such as figure 1 , figure 2 As shown, a hook A3 is connected to each of the upper four corners of the inner wall of the washing machine outer box 1, and four hooks B4 are connected to the lower part of the outer wall of the washing machine washing tub 2 at circumferential intervals. A hanger rod 5 is hung on it and is stabilized by a pad 6, and a shock absorber 7 is hung on the hook B. The shock absorber has a casing 8, and the lower end of the hanger rod 5 extends into the casing of the shock absorber. A support body 9 is arranged in the shell, the lower end of the boom is connected with the support body, a shock absorbing spring 10 is arranged between the top of the shell and the support body, and the upper part of the shell is hung on the hook B so that the shock absorber is connected to the hook B, A spring A14 is arranged at the bottom of the casing, a magnetic iron core 12 is placed on top of the upper end of the spri...

Embodiment 2

[0021] In this example, the sensing device, such as Figure 4 As shown, the shock-absorbing spring is composed of shock-absorbing spring A10-1 and shock-absorbing spring B10-2 coaxially interlocked. The height of shock-absorbing spring B is smaller than that of shock-absorbing spring A. In the initial state, one end of shock-absorbing spring B is Keep it in the air (when the lower end of the shock absorber spring B is against the support, the upper end remains in the air). The other structures are the same as the implementation one.

[0022] When water is added into the washing tub, as in the first embodiment, the casing of the shock absorber moves downward, and the shock absorber spring A is compressed first. Continue to add water, the shock spring B is compressed. Suppose the elastic coefficient of damping spring A is K1, the free length is La, the elastic coefficient of damping spring B is K4, the free length is Lb, the total stroke of the washing tub is L, and when the d...

Embodiment 3

[0024] In this example, the sensing device, such as Image 6 As shown, what is different from Example 2 is that the support body 9 is provided with a cavity that opens downward, and the cavity is provided with a guide rod 15, the lower end of the guide rod is connected to the magnetic iron core 12, and the connection between the guide rod and the magnetic iron core has a diameter The length of the guide rod is to keep the upper end of the guide rod away from the top of the cavity, the spring B13 is sleeved on the guide rod, the lower end of the spring B is placed on the step of the guide rod, and the upper end of the spring B is higher than the guide rod. top of the rod. The other structures are the same as the second implementation. In this example, while maintaining the structure and function of the spring B, the distance between the magnetic iron core and the support body can be reduced, which is beneficial to the miniaturization of the sensing device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com