Elastic sheet for motorcycle disc brake pump

A motorcycle and shrapnel technology, which is applied to bicycle accessories, bicycle brakes, brake parts, etc., can solve the problems that two brake pads cannot be bonded synchronously and the braking effect is not ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

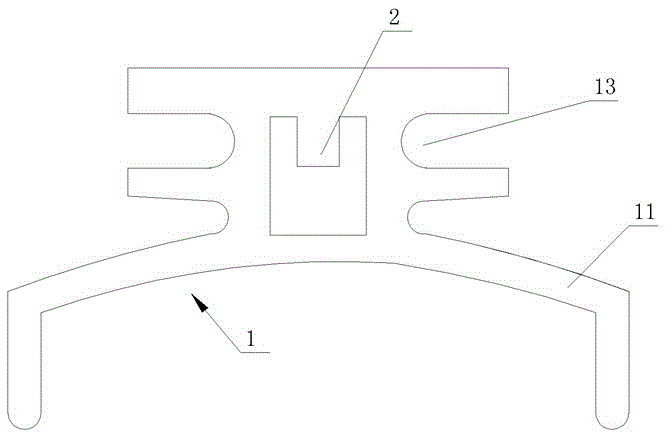

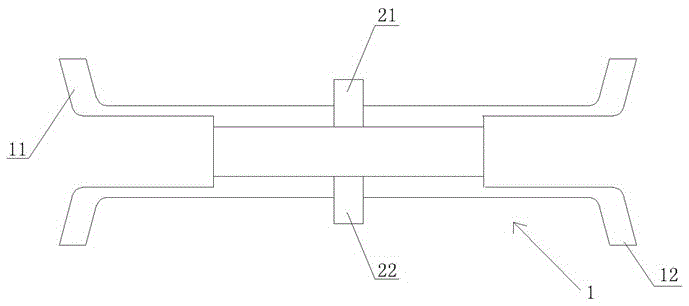

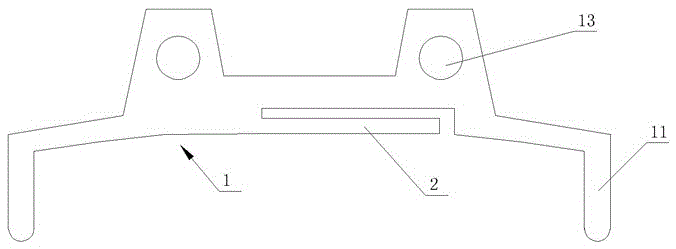

[0022] Referring to the accompanying drawings, a shrapnel for a motorcycle disc brake pump includes a V-shaped shrapnel body 1, the shrapnel body 1 is composed of a left wing 11 and a right wing 12 connected, and the left wing 11 and the right wing The lower part of 12 is provided with a mounting hole 13 for installing the shrapnel on the disc brake pump. The mounting hole 13 can be in the shape of a semi-circular hole or a round hole. The mounting hole 13 is pierced with a guide pin so that the shrapnel is installed on the shrapnel mounting seat of the disc brake pump. Above, the upper part of the left wing 11 and the right wing 12 is a semi-enclosed frame structure, and the semi-enclosed frame is clamped with the outer periphery of the brake pads. Under the elastic force of the shrapnel, the two brake pads are completely separated to both sides. Due to the joint connection between the shrapnel and the disc brake pad, in the non-braking state, the shrapnel is V-shaped, so the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com