Box for new material coating machine

A coating machine and new material technology, applied in the field of coating machines, can solve the problems of not achieving the best use effect, complex structure of the coating machine box, affecting product quality, etc., to achieve good fixing effect, beautiful surface quality, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Corresponding reference characters indicate corresponding parts throughout the views of the drawings.

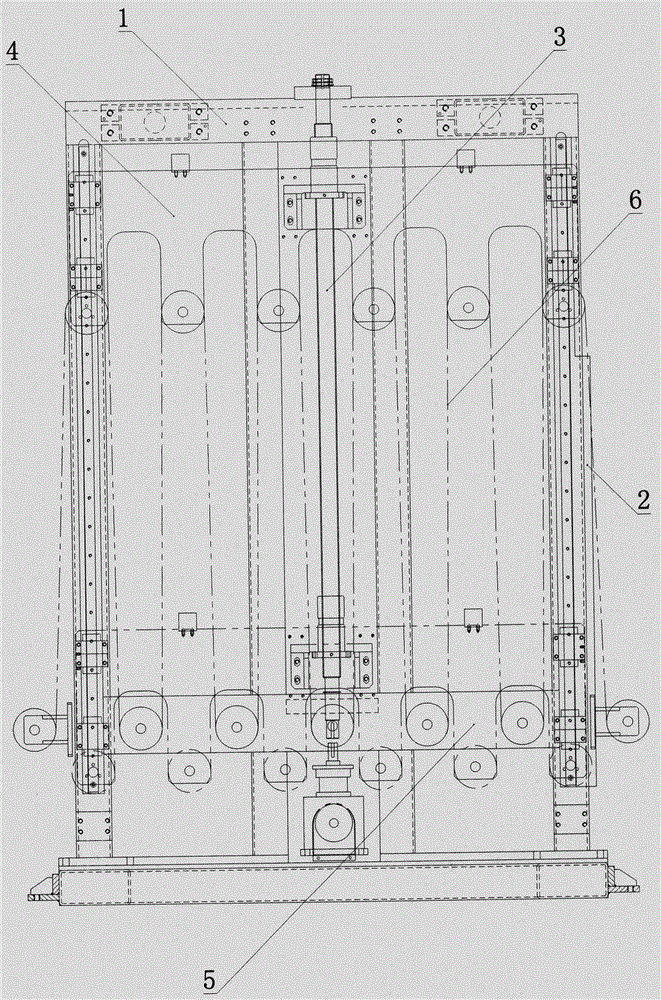

[0020] A box body for a new material coating machine, including a fixed frame 1, a linear guide rail 2, a ball screw 3, a floating frame 4, a box body 5, a floating frame 4, a fixed frame 1, a linear guide rail 2, and a ball screw 3 is fixed on the box body 5, the floating frame 4 is connected with the box body 5 through the slider of the linear guide rail 2 and the nut on the ball screw 3, and the floating frame 4 is driven by the ball screw 3.

[0021] When in use, the base material 6 passes alternately between the fixed frame 1 and the floating frame 4; It is connected with the nut on the ball screw 3 and the box body 5, and the floating frame 4 is driven by the ball screw 3, and the linear guide 2 acts as a guide to ensure that the level of the floating frame 4 is parallel, and the parallel level can reach within 1mm.

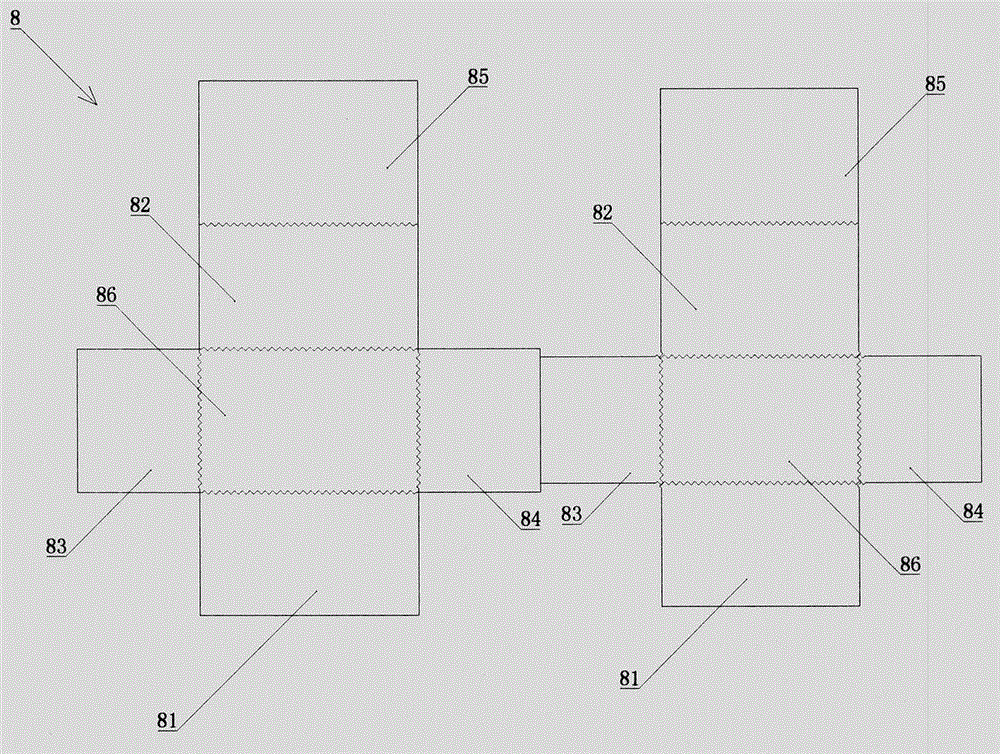

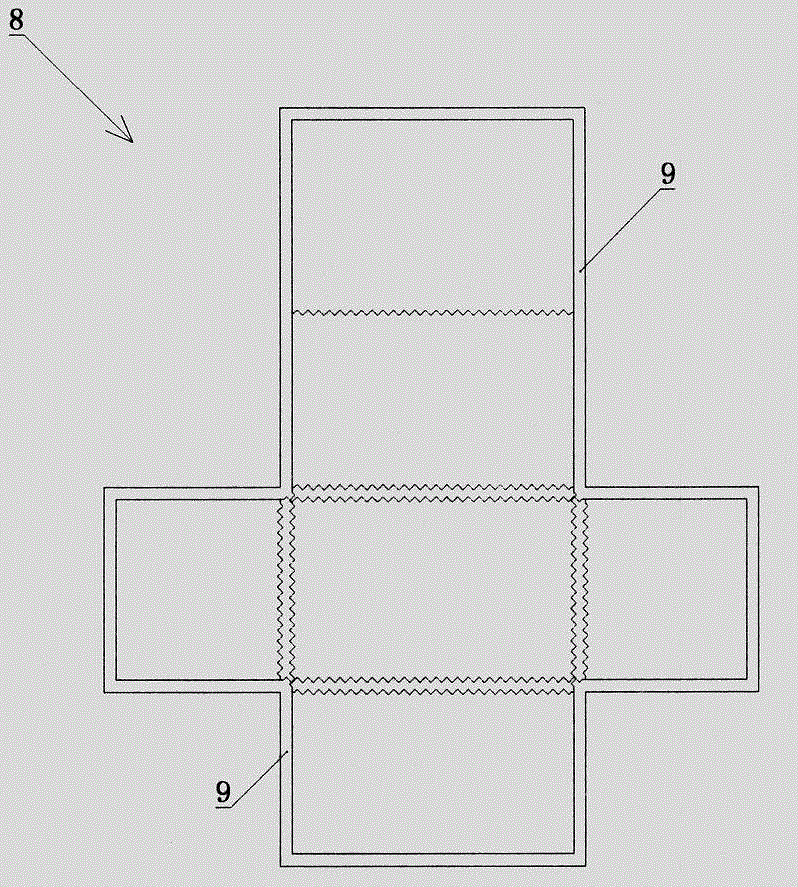

[0022] In a preferred embodiment, the board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com