Weld holder of mast oil cylinder installation base of forklift

A forklift mast and mounting seat technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the requirements of coaxiality and high tolerance requirements, and cannot guarantee the reliable installation of oil cylinders, and cannot guarantee the same installation holes. Axis and other issues, to ensure reliable installation, to ensure the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

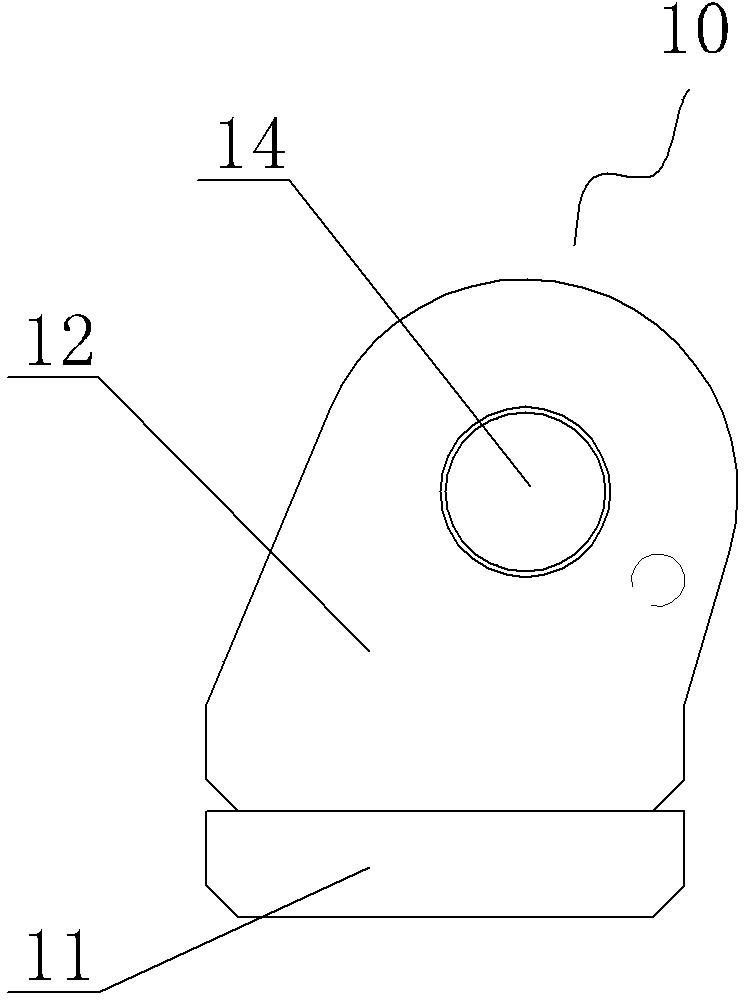

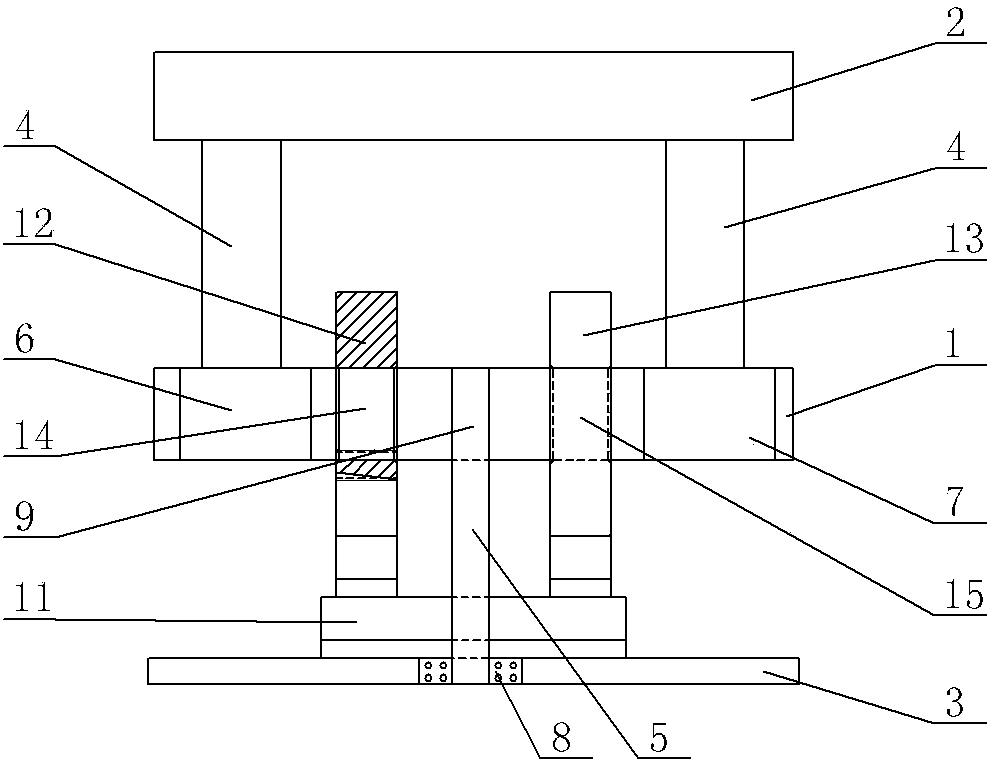

[0011] See figure 2 , the present invention includes a positioning shaft 1, a horizontal hanger 2 and a horizontal bottom plate 3, the horizontal hanger 2 is connected with the positioning shaft 1 through a vertical pull rod 4, the side of the horizontal bottom plate 3 is connected with the positioning shaft 1 through a rotating connecting rod 5, and the positioning shaft 1. The horizontal hanger 2 and the horizontal bottom plate 3 are kept horizontal and parallel to each other. There are two vertical pull rods 4, and the two vertical pull rods 4 are respectively connected to the positioning shaft 1 through hoops 6 and 7; Card access. When welding the base 11 and the two support ears 12, 13, the base 11 is placed on the horizontal bottom plate 3, the positioning shaft 1 passes through the installation holes 14, 15 of the two support ears 12, 13, and the two vertical pull rods 4 The hoops 6, 7 are respectively engaged and connected with the positioning shaft 1 located outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com