Automatic turn-over machine for lead-acid storage battery

A lead-acid battery, automatic turning technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

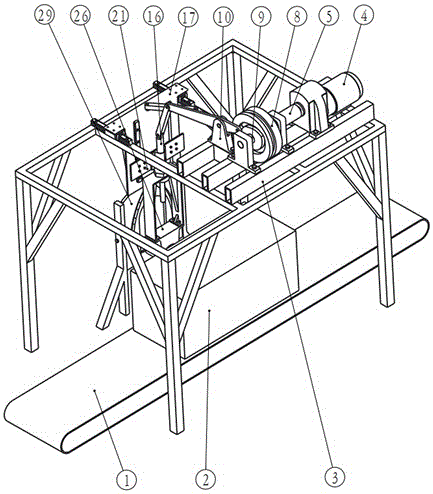

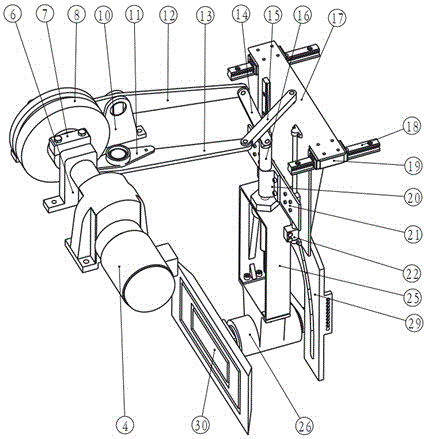

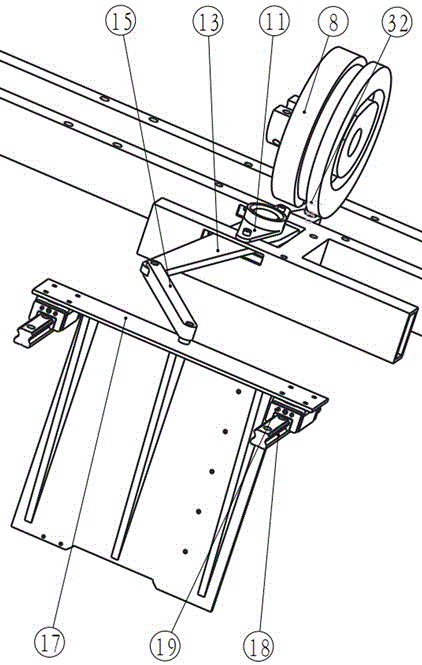

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] Such as Figure 1-5 As shown, the present invention includes a frame 3, a main transmission device, a translation cam linkage mechanism, a lifting cam linkage mechanism and an overturning mechanism; The driving shaft 9, the cam 8 and the pressing block 7; the decelerating motor 4 and the bearing support 6 are respectively fixed on the frame 3 by screws, the driving shaft 9 is installed in the bearing support 6, and the driving shaft 9 passes through the shaft coupling Device 5 links to each other with the shaft of reduction motor 4, and cam 8 is installed on the driving shaft 9 by pressing block 7 and screw.

[0017] Described translation cam link mechanism comprises swing arm support 11, swing arm 13, connecting arm 15, seven-shaped plate 17, slide block 19, horizontal guide rail 18 and cam follower 32; Described swing arm support 11 and the horizontal guide ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap