Control method for throttling freezing type cryosurgery device

A control method and surgical technology, applied in the field of medical devices for cryosurgical treatment, can solve the problems of low-temperature working medium waste in gas throttling cryosurgical equipment, and achieve the effects of improving gas utilization, reducing costs, and increasing hyperthermia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

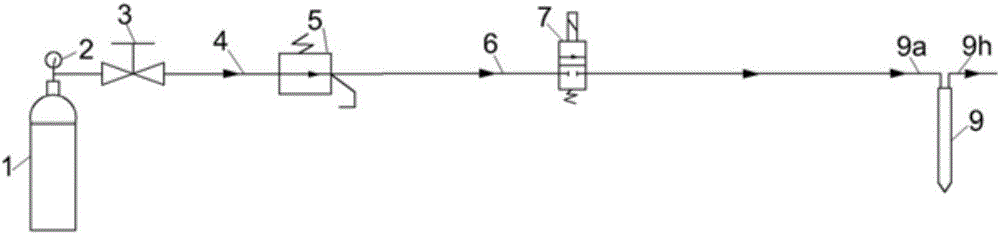

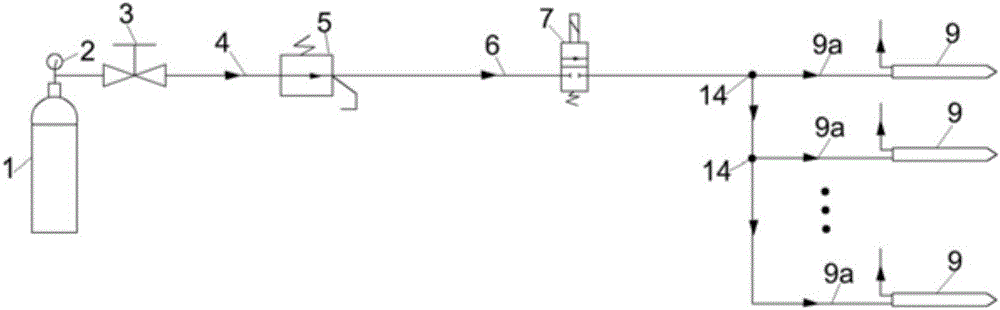

[0037] Embodiment 1: as figure 1 As shown, the structure of the throttling refrigeration type cryosurgical device used is: comprising a refrigeration gas circuit and a refrigerator 9, the refrigeration gas circuit includes a gas inlet pipe 4 connected in sequence with the gas outlet of the high-pressure gas source 1 and the refrigeration gas main pipe 6. The gas input pipe 4 is provided with a barometer 2 and a gas source pressure regulating valve 3, and the gas source pressure regulating valve 3 of the present invention is opened and closed manually or electrically. A pressure-limiting valve 5 is provided at the connection between the gas input pipe 4 and the refrigerated gas main pipe 6 , and a refrigerated solenoid valve 7 is provided on the refrigerated gas main pipe 6 . Such as image 3 As shown, multiple refrigerator inlet pipes 9a can also be connected to the end of the frozen gas main pipe 6 through the second tee 14 connected in series, and one refrigerator is connec...

Embodiment 2

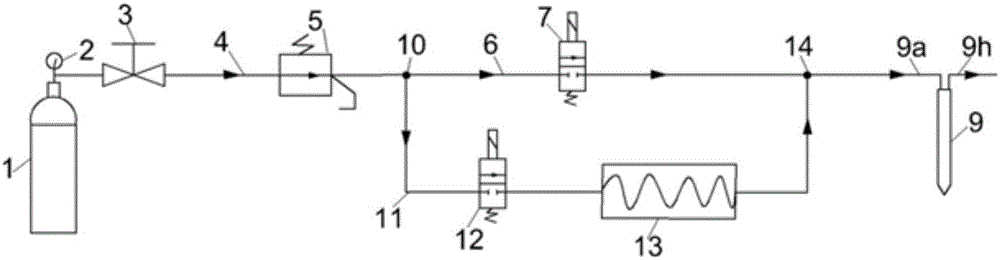

[0040] Embodiment 2: as figure 2 As shown, a kind of embodiment that can preheat the gas, the structure of the throttling refrigeration type cryosurgical device used is: including the freezing gas circuit, the heating gas circuit 11 and the freezer 9, and the said freezing gas circuit includes the high-pressure gas source 1 The gas inlet pipe 4 connected with the gas outlet in sequence and the refrigerated gas main pipe 6, the gas input pipe 4 is provided with a barometer 2 and a gas source pressure regulating valve 3, the gas input pipe 4 and the refrigerated gas main pipe 6 A pressure limiting valve 5 is provided at the joint of the refrigerated gas main pipe 6, and a refrigerated solenoid valve 7 is provided on the refrigerated gas main pipe 6, and a first Tee 10, a second tee 14 is provided at the connection between the frozen gas main pipe 6 and the refrigerator inlet pipe 9a, and is connected to the refrigerator; the heating gas circuit 11 is connected to the first thre...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap