Anti-backward motion device of car

A rear-prevention and automobile technology, which is applied to vehicle components, transportation and packaging, brakes, etc., can solve problems such as car slipping accidents, vehicle damage, car crashes, etc., and achieve the effect of preventing back slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

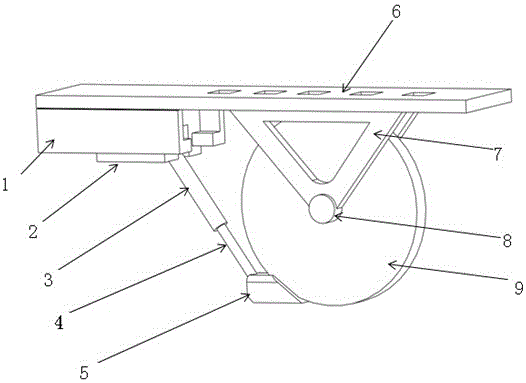

[0024] Embodiment 1: see Figure 1-5 .

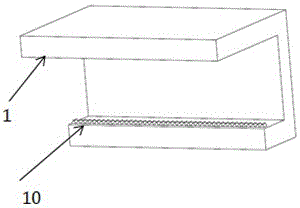

[0025] An automobile anti-rollback device, which includes a frame connection part and a telescopic thrust part, the frame connection part is a main frame 1 with a bottom opening, and the telescopic thrust part includes a sliding connection with the opening end of the main frame 1 The slider 2, the first drive mechanism that drives the slider 2 to move horizontally, the stopper that moves integrally with the slider 2, and the second drive mechanism that drives the retraction of the stopper, drives the second drive mechanism a first rotating mechanism for rotating and a second rotating mechanism for driving the stop block to rotate;

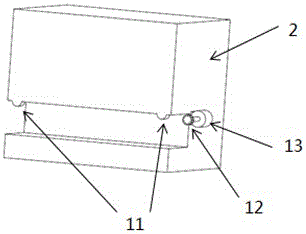

[0026] Described first driving mechanism comprises roller 11, first stepper motor 13 and first gear 12, and described slide block 2 is provided with a chute, and roller 11 is housed on the inner sidewall of chute opening, and one side of chute A first stepping motor 13 is provided, the output end of the fi...

Embodiment 2

[0032] Example 2, see Figure 1-7 , including vehicle frame 6, suspension suspension 7, vehicle axle 8, wheel 9, main frame 1 and vehicle frame are fixedly connected by bolts, when the car is on a ramp to stop and start, the driver turns on the control switch of the device in the cab, When the first stepper motor 13 drives the gear 12 to move on the rack 10 so as to drive the slider 2 to slide to the limit tooth position at one end of the rack 10 to the rear of the frame, the second stepper motor 14 drives the drive gear 16 to move Rotation, of course, stepper motors can also achieve this function, because stepper motors can precisely control the number of turns or strokes of rotation. Because the driving gear 16 is fixedly connected with the hydraulic cylinder 15 at the top of the primary hydraulic rod 3 and the top, so the driving gear 16 rotates, and the hydraulic rod 3 also rotates to a certain angle. After the driving gear stops rotating, the hydraulic cylinder 15 begins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com