A Simple Pose Compensation Mechanism for Automatic Docking and Release Connector of Launch Vehicle

A technology of automatic docking and compensation mechanism, applied in transportation and packaging, space navigation equipment, space navigation ground equipment, etc., can solve problems such as complex structure, achieve small size, improve force performance, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

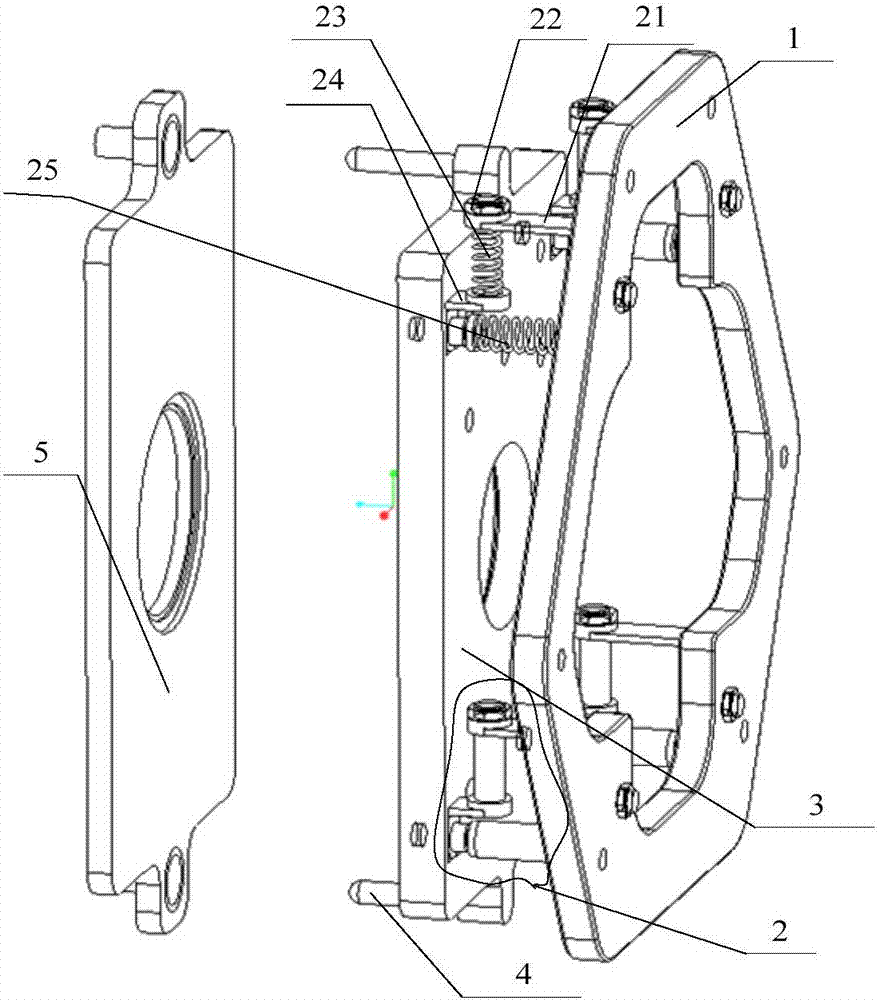

[0016] Such as figure 1 As shown, the simple pose compensation mechanism for the automatic docking and venting connector of the launch vehicle of the present invention includes a moving platform 1 and a ground connector panel 3 parallel thereto. The moving platform 1 and the ground connector panel 3 pass through at least four Evenly distributed elastic parts 2 are connected.

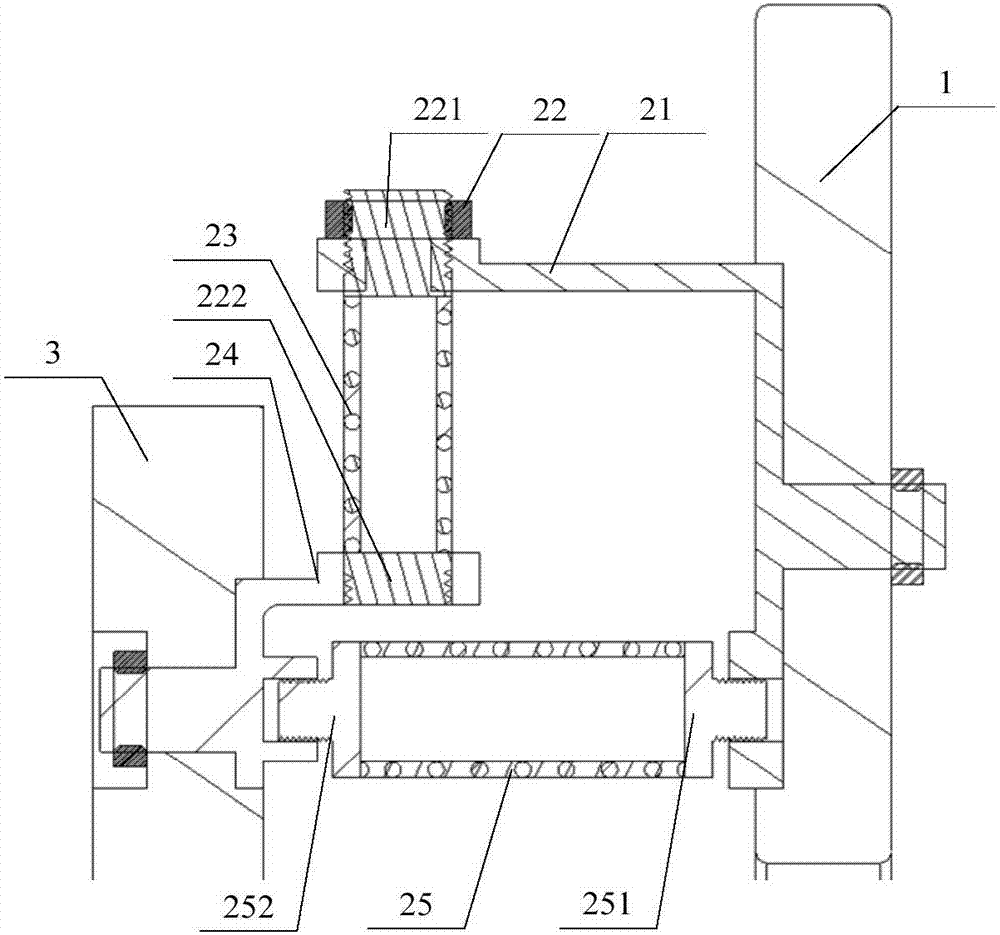

[0017] As a preference, such as figure 2 As shown, the elastic component 2 includes a mounting seat A21, an adjusting nut 22, an upper and lower compound rubber spring 23, a mounting seat B24, a front and rear compound rubber spring 25 and an adjusting screw 221;

[0018] The mounting base A21 is fixedly mounted on the rear side of the moving platform 1, the mounting base B24 is fixedly mounted on the front side of the ground connector panel 3, and the two ends of the front and rear composite rubber springs 25 are fixedly connected to the mounting base A21 and the mounting base B24 respectively, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com