Grounding clip for an airbag ignition system

一种气囊点火、接地夹的技术,应用在连接部件保护接地/屏蔽装置、连接、电气元件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

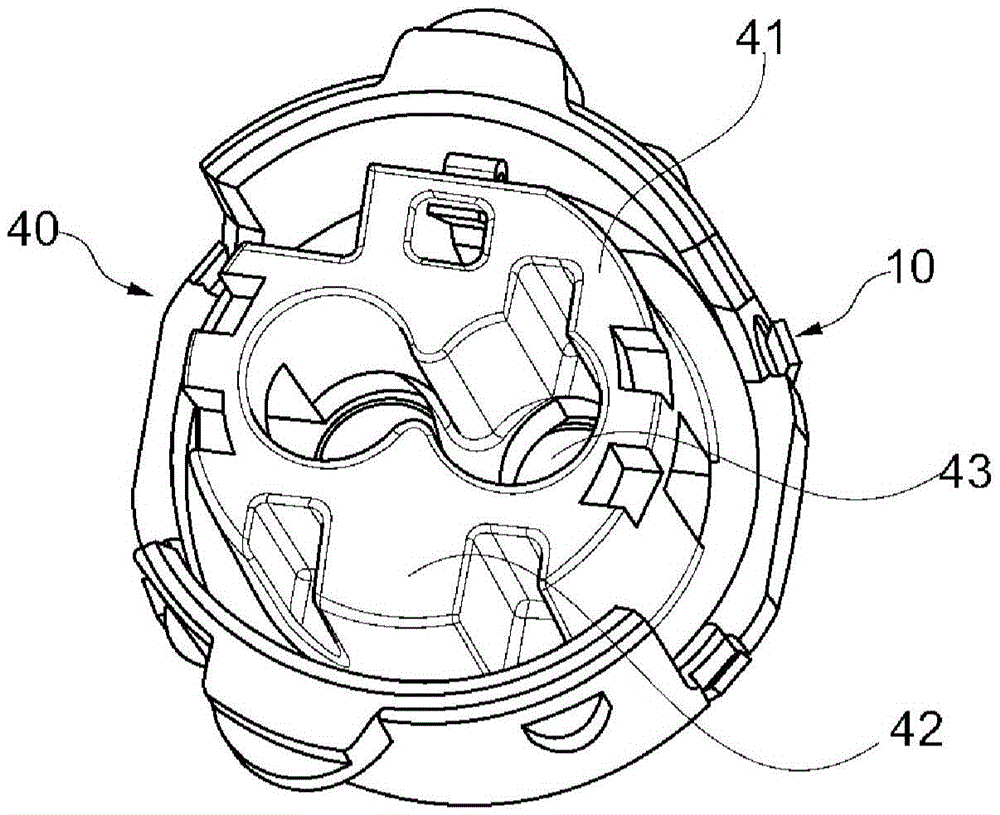

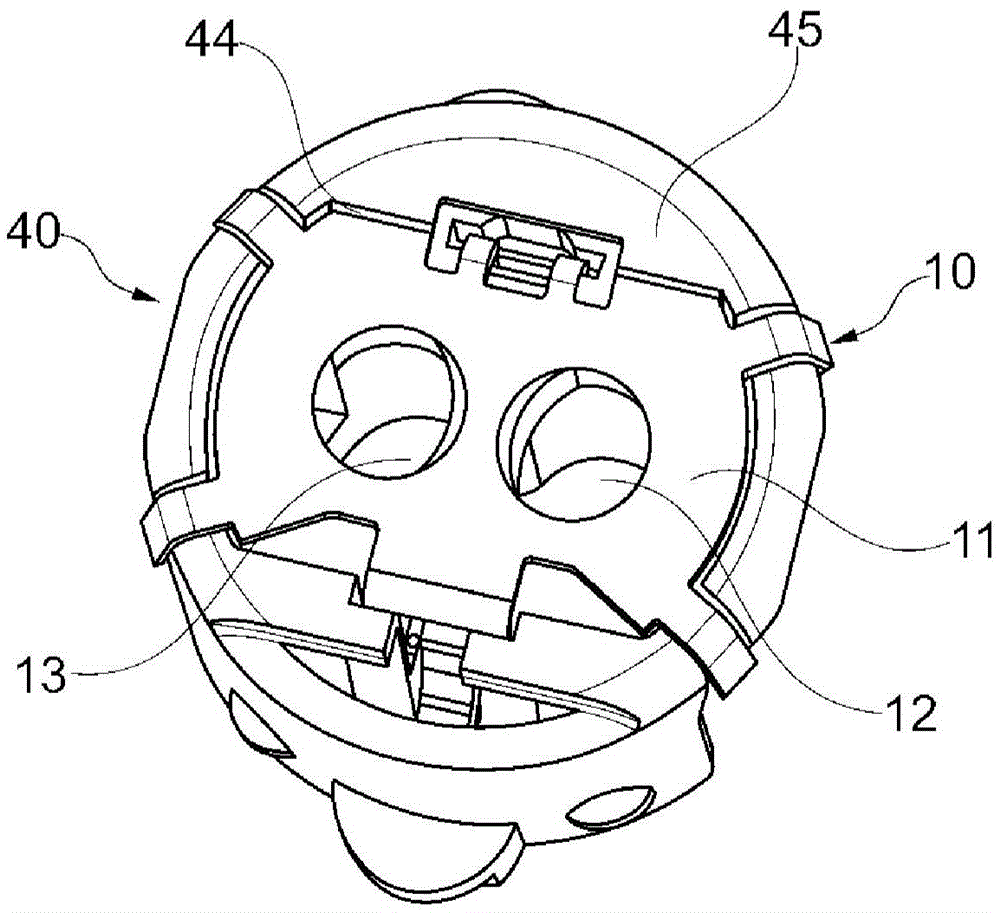

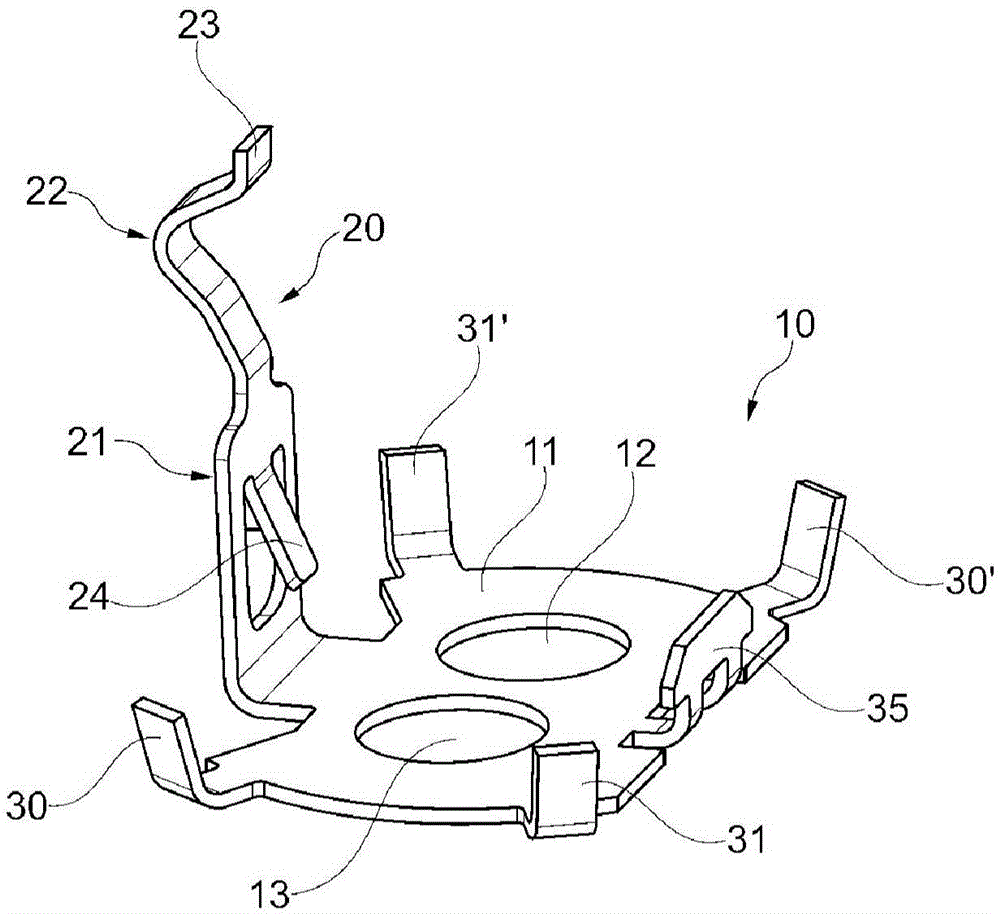

[0028] figure 1 A three-dimensional view of the airbag retainer insert 40 is shown when viewed in the mating direction. The airbag retainer insert 40 may be abbreviated as retainer 40 or insert 40 . The holder 40 has a counterpart face 41 comprising a coding element 42 and a hole 43 in the shape of an hour glass. In the assembled state, the insert 40 will be fitted in the socket of the airbag squib and the contact pins of the squib will extend into this hole 43 . The ground clip 10 is mounted to the insert 40 from its bottom. ground clip 10 is shown in more detail in the Figure 4 middle. available from figure 1 As can be seen in the illustration, the grounding clip 10 does not have any means for short-circuiting the pins of the airbag squib, such as corresponding contact tongues, which would protrude into the hole 43 in the state of the art. In other words, the grounding clip 10 is freed from the means of shorting the pins of the airbag squib.

[0029] figure 2 shows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com