Segmental transverse unbonded prestressed assembled prefabricated hollow slab bridge structure and its construction technology

A technology of hollow slab bridge and construction technology, which is applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of large prestress loss and long force transmission path, and achieve high prestress efficiency, improved integrity, and easy replacement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

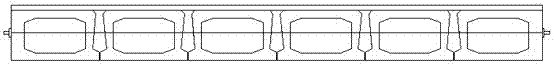

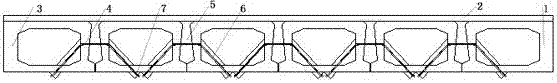

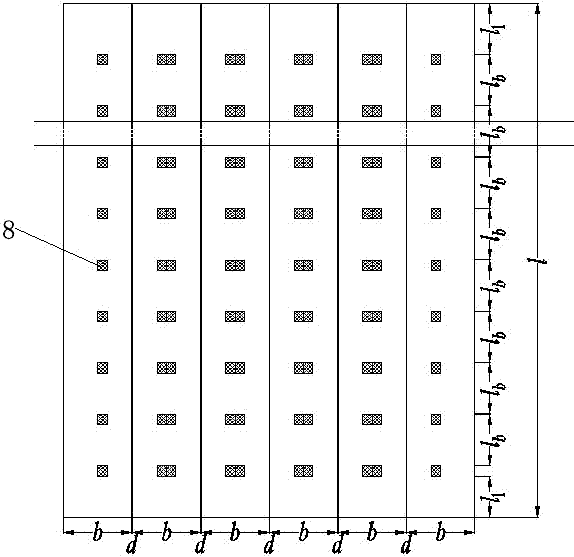

[0032] Such as Figure 2-11 A segmental transverse unbonded prestressed assembled prefabricated hollow slab bridge structure, comprising a hollow slab 1 and a concrete layer 2 laid on the hollow slab, the hollow slab is composed of at least two hollow slabs 3 arranged in sequence , the gap between the webs 4 of adjacent hollow plates forms a hinge joint 5, and at least two adjacent hollow plates are connected by prestressed beams 6, and anchoring devices 7 are provided at both ends of the prestressed beams. The anchoring device of the present invention is an anchor. An anchor groove 8 is arranged on the bottom plate. The prestressed beam extends out of the anchor groove, and the anchor is fixed at the end of the prestressed beam. According to the design requirements of different working conditions, the prestressed beam Tension is carried out and finally tightened.

[0033] Such as Figure 2-9 As shown, that is, the prestressed beam passes through the bottom part of the I hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com