Self-reposition friction energy dissipation support based on shape memory alloy

A memory alloy, friction energy dissipation technology, applied in the field of structural shock absorption, can solve the problems of difficult maintenance of viscous dampers, easy aging of viscoelastic dampers, plastic residual of mild steel dampers, etc., so as to improve the shock absorption effect and structure. Simple, energy-efficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below by means of embodiments and in conjunction with the accompanying drawings.

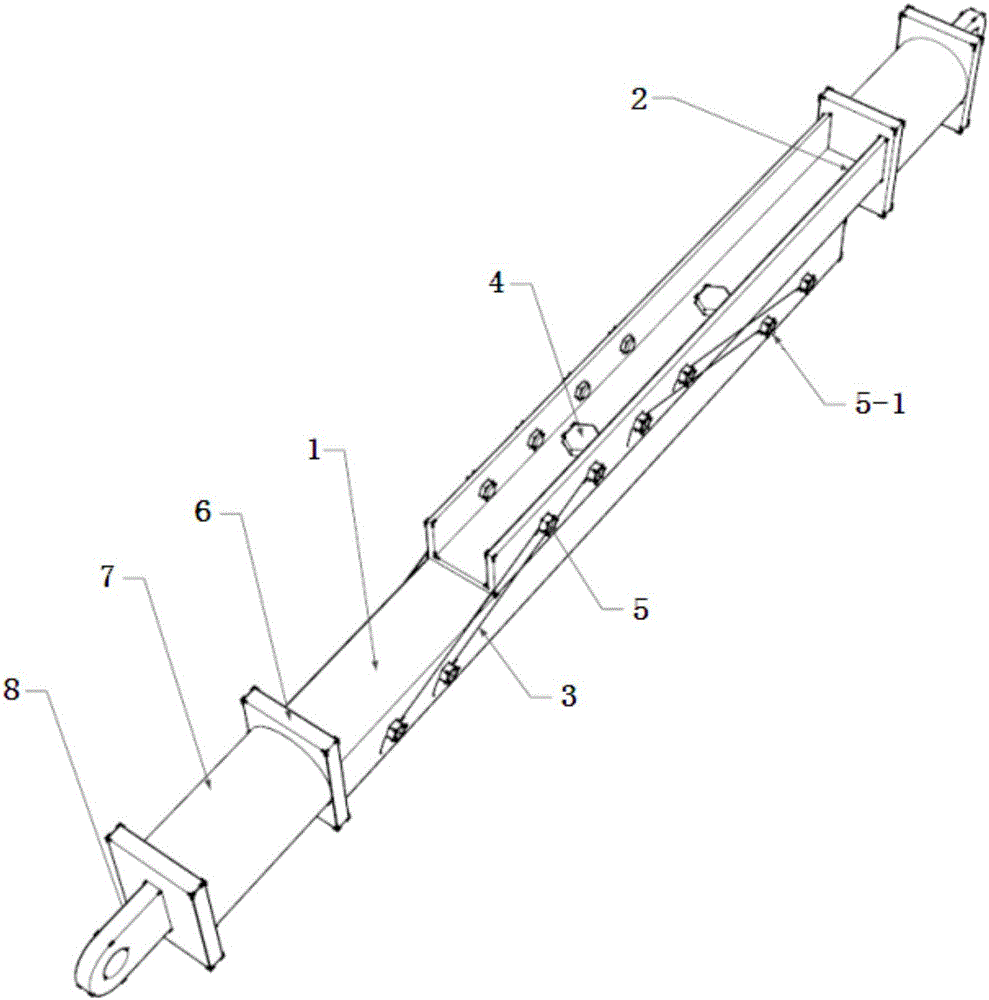

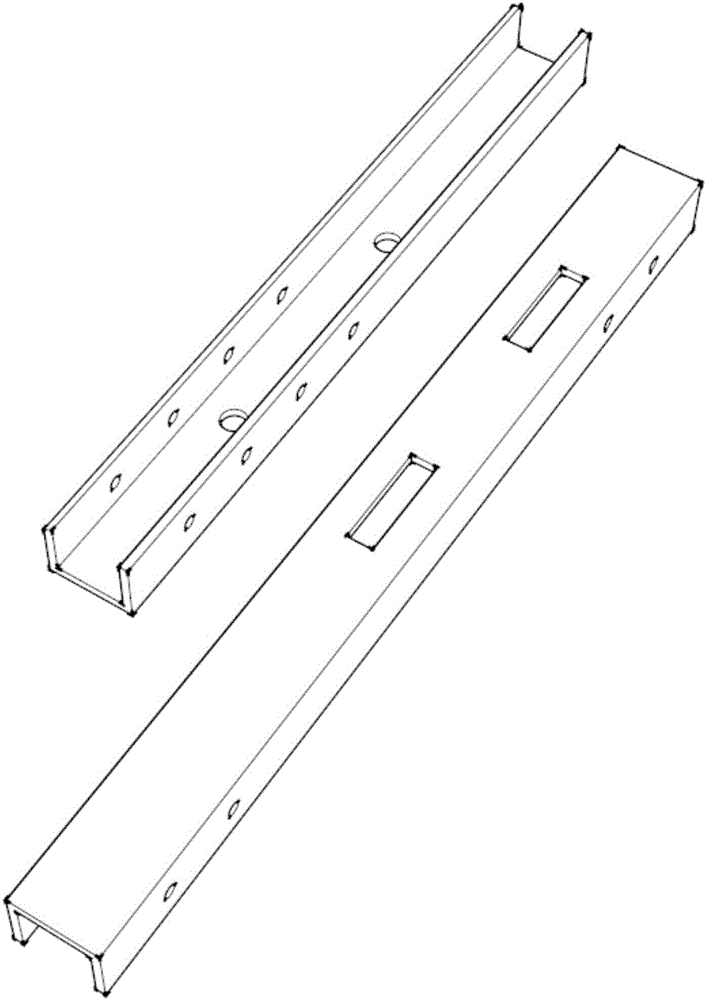

[0015] Such as Figure 1-Figure 4 As shown, a self-resetting frictional energy-dissipating support based on a shape memory alloy includes a first channel steel 1 and a second channel steel 2, and the outer ends of the first channel steel 1 and the second channel steel 2 are respectively connected with circular tubes 7 and connecting plate 8; the opening of the first channel steel 1 is downward, and the opening of the second channel steel 2 is upward, and the two press the contact surface through the connecting piece 4 to provide friction; Four first bolts 5 distributed equidistantly, four second bolts 5-1 are respectively arranged on the left and right sides of the flange of the second channel steel 2, and the second bolts 5-1 are symmetrical with respect to the central axis of the second channel steel 2 Setting; the first bolt 5 is connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com