3D sewing device

A sewing and equipment technology, applied in the field of 3D sewing equipment, can solve problems such as complex three-dimensional surface shape and complex stitch trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

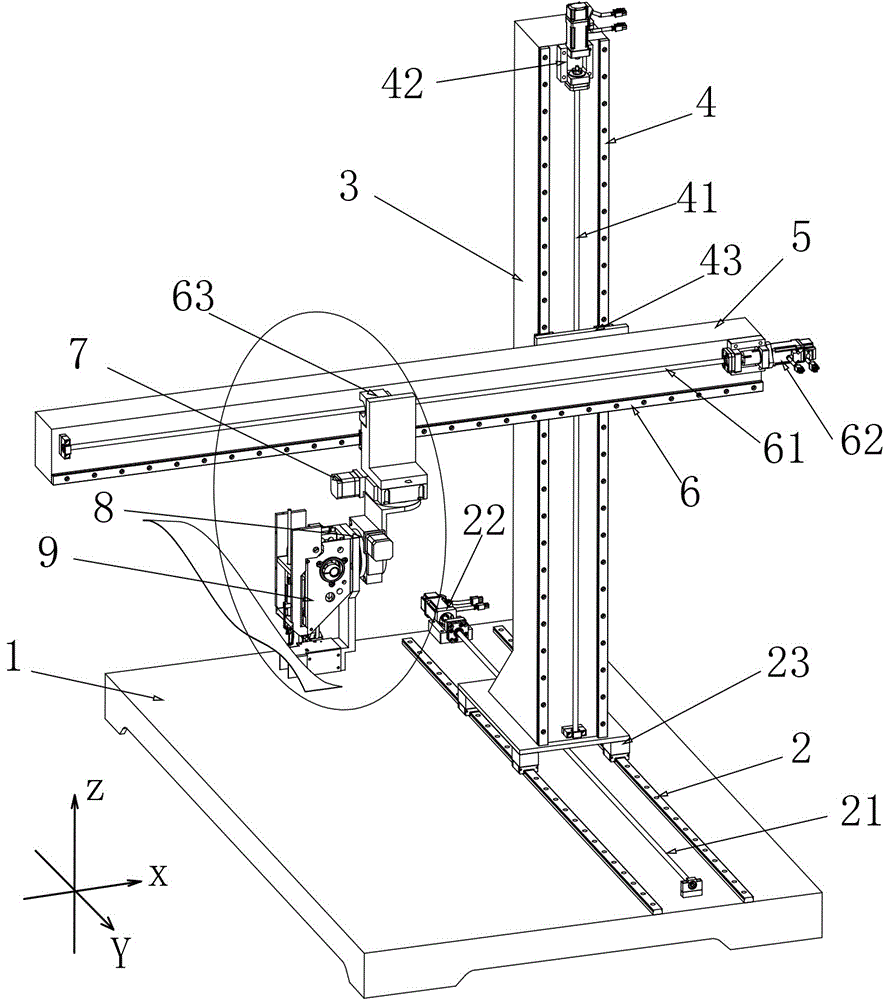

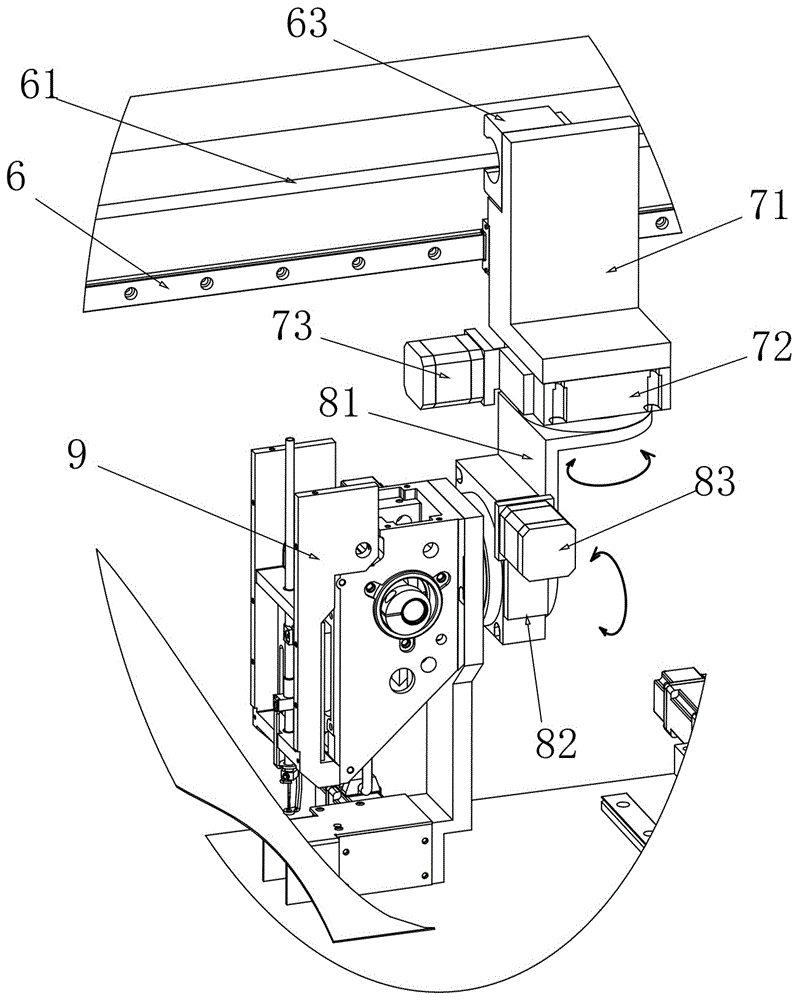

[0012] See attached picture. This embodiment includes a base 1, on which a first guide rail 2 arranged along the Y-axis direction is fixed, on which a first screw 21 and a first drive motor 22 for driving the first screw 21 are arranged, and A slide block 23 is slidably installed on the first screw mandrel 21; a longitudinal pillar 3 arranged along the Z-axis direction is installed on the first slide block 23, and the second guide rail 4 is fixed on the longitudinal pillar 3, and the second guide rail 4 A second screw mandrel 41 and a second drive motor 42 for driving the second screw mandrel 41 are provided, and a second slider 43 is slidably mounted on the second screw mandrel 41; The horizontal pillar 5 that is set, the third guide rail 6 is fixed on the transverse pillar 5, the third guide rail 6 is provided with the third screw mandrel 61 and the third drive motor 62 that drives the third screw mandrel 61, the third slide block 63 is slidably installed On the third screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com