Automatic pocket patching machine multi-thread sewing adjustment pressing device

A pocketing machine and pressure-regulating technology, which is applied to sewing equipment, sewing machine components, cloth pressing mechanism, etc., can solve the problems of clothing appearance and quality degradation, and seam sewing is not smooth and uniform enough, so as to achieve smooth sewing and ensure smooth sewing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

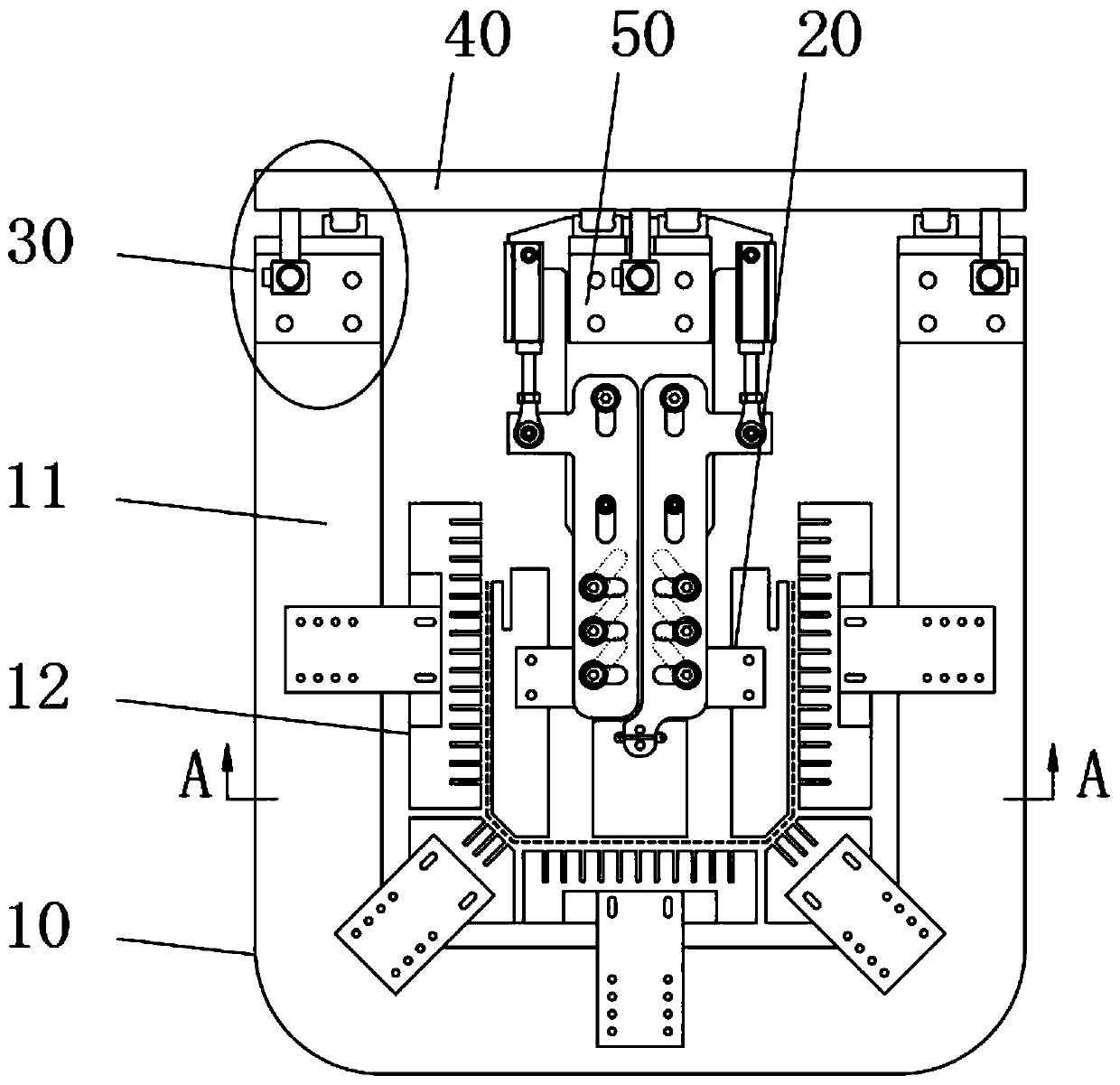

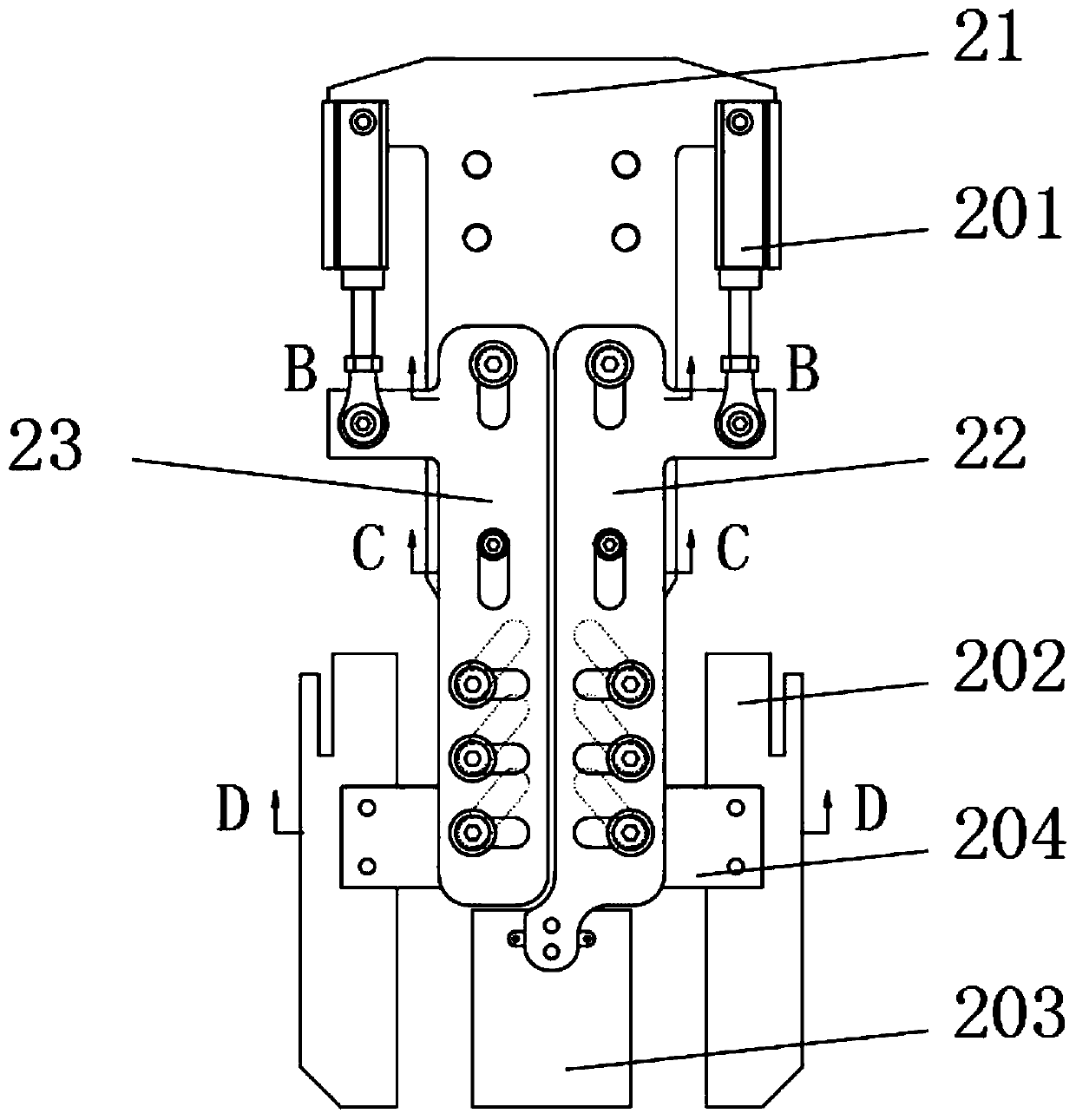

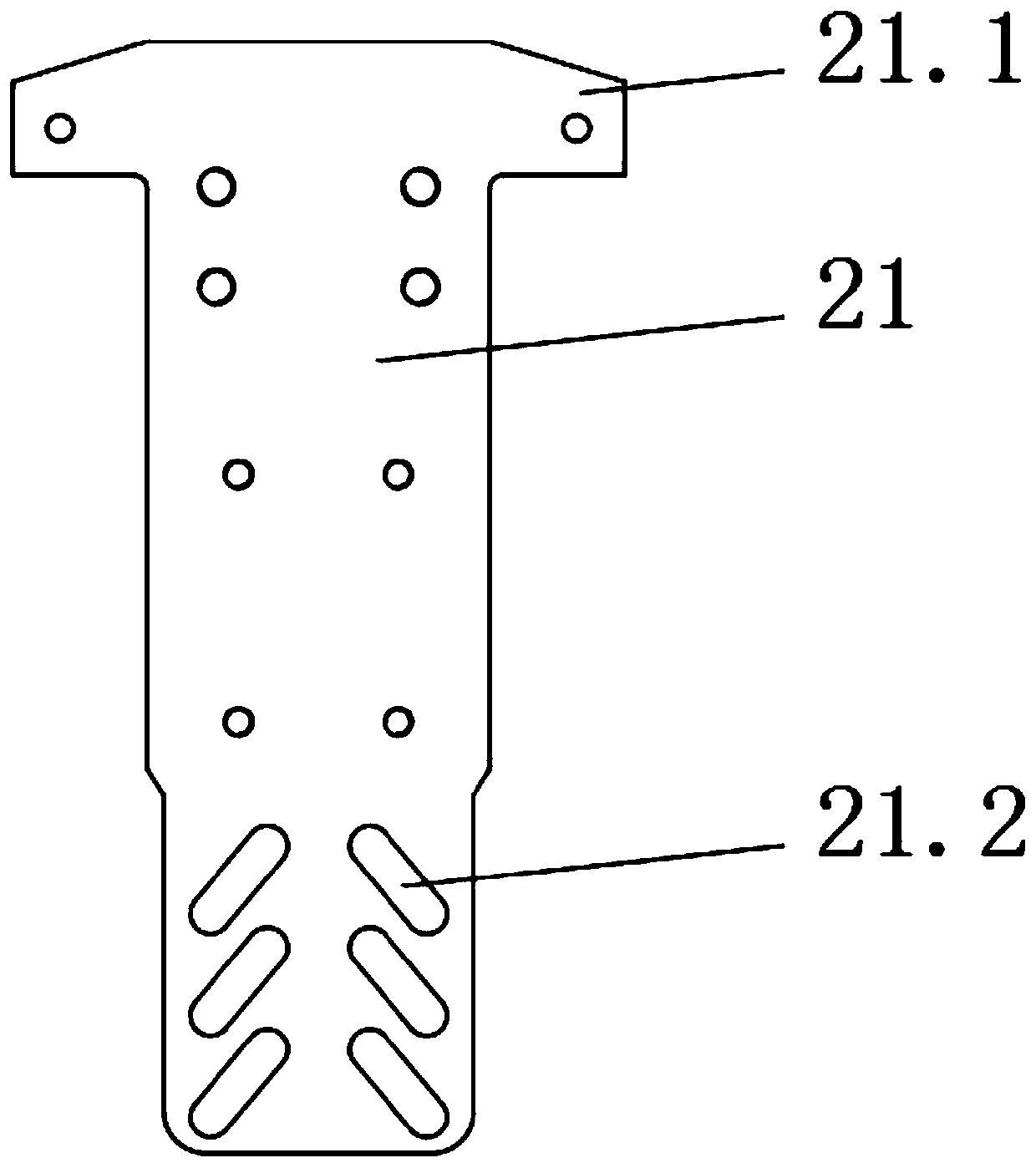

[0041] Embodiment one, with reference to Figure 1-11, an automatic bag sticking machine multi-thread sewing adjustment pressing device, including a pressing frame 10, an adjustment mechanism 20, a side lifting assembly 30, a moving plate 40 and a middle lifting assembly 50, the pressing frame 10 includes an outer pressing frame 11, an inner Press frame 12, and one end of the outer press frame 11 is provided with a side lift assembly 30, an adjustment mechanism 20 is provided at the middle position inside the press frame 10, and one end of the adjustment mechanism 20 is provided with a middle lift assembly 50, and the adjustment mechanism 20 includes a guide substrate 21 , right guide plate 22, left guide plate 23, adjusting cylinder 201, side pressure claw 202, end pressure claw 203, connecting plate 204, first contour column 205, second contour column 206, limit sleeve 207, the first Third-level column 208, one end of the guide base plate 21 is provided with an ear seat 21.1...

Embodiment 2

[0042] Embodiment two, refer to Figure 3-10 , the third contour column 208 runs through the first guide groove 21.2 and the third guide groove 22.3 to connect with the connecting plate 204, and the inside of the first guide groove 21.2 and the third guide groove 22.3 is slidingly connected with the side surface of the third contour column 208, The side surface of the first contour column 205 is slidably connected with the second guide groove 22.2, and the second contour column 206 is slidably connected with the second guide groove 22.2 through a limit sleeve 207. The right guide plate 22, The left guide plate 23 and the connecting plate 204 are all attached to the guide base plate 21 under the limits of the first contour column 205, the second contour column 206 and the third contour column 208, which ensures that the side pressing claws 202 and the end The stability of the pressure claw 203 when moving can avoid the service life of the adjustment mechanism being affected by ...

Embodiment 3

[0043] Embodiment three, refer to Figure 12-16 , the inner pressure frame 12 is composed of a plurality of inner pressure plates 12.1 of different shapes, and each inner pressure plate 12.1 is fixed on the inner side of the outer pressure frame 11 through a corresponding adjustment plate 11.2 and a backing plate 11.3, and the outer pressure frame 11 is in a "U" shape structure, and the bottom surface of the outer pressure frame 11 is glued with a rubber pad 11.1, and one end surface of the adjustment plate 11.2 is provided with an adjustment groove 11.4, which is used to adjust the position of the inner pressure plate 12.1, the inner pressure plate 12.1, the side pressure claw 202 and the end pressure claw 203 Rubber pads 11.1 are adhered to the bottom surface to improve the adhesion to the material sheet and patch pocket;

[0044] The side lifting assembly 30 includes a side lifting cylinder 301, a side connecting column 302, a side connecting corner piece 303, a side slider...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com