Electronic certificate sewing equipment with automatic aligning function

A technology of electronic certificates and stitching equipment, which is applied in binding and other directions, can solve the problems of reducing the yield rate, time-consuming and labor-consuming, binding deviation, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

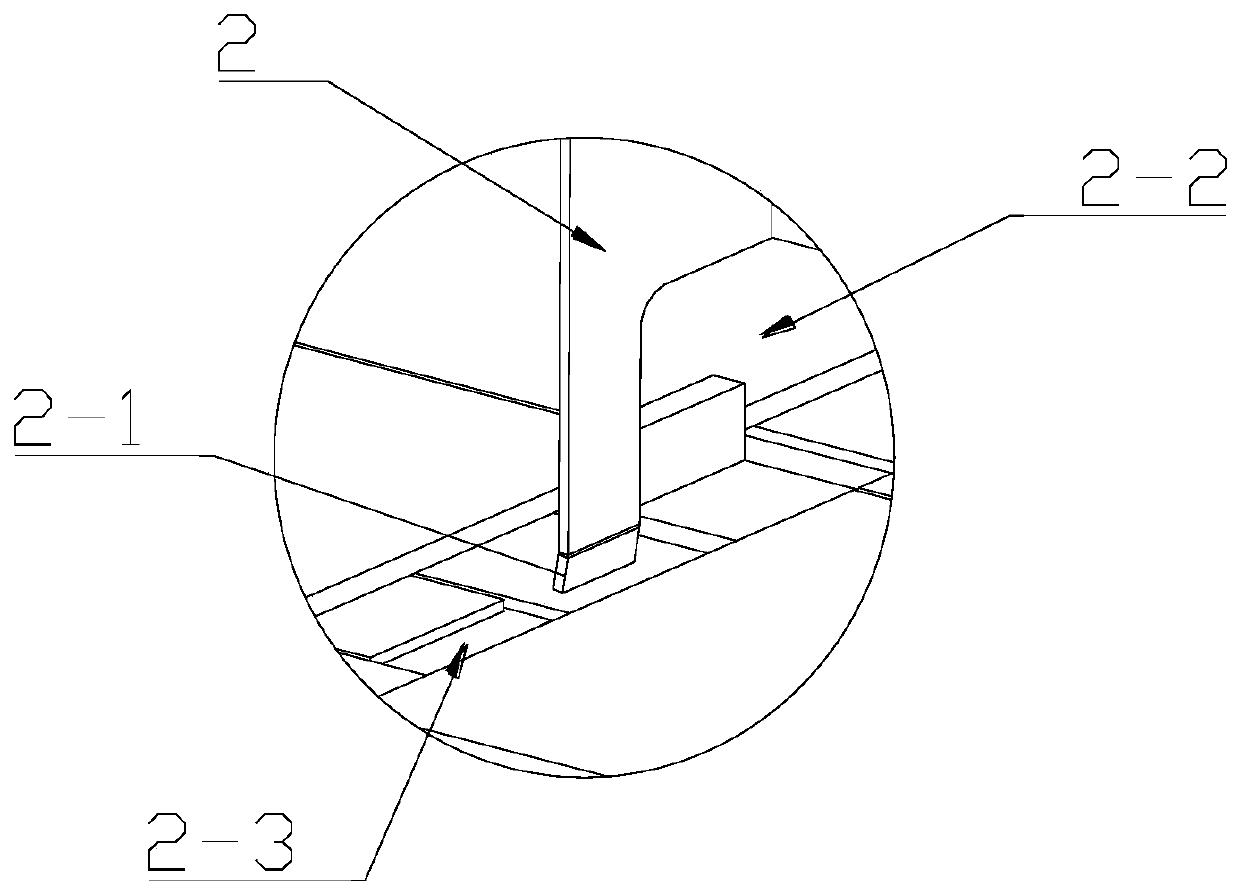

[0053] see Figure 4 The positioning mechanism includes a positioning seat 9 arranged on the support frame 1 and a driving mechanism for driving the baffle 2 to swing, wherein the driving mechanism includes a first connecting block 11 arranged on the upper end of the baffle 2, and a first connecting block 11 arranged on the upper end of the baffle 2 The second connection block 10 on the positioning seat 9, the swing motor 12 and the first screw drive mechanism, wherein, the two ends of the baffle plate 2 are connected to the positioning seat 9 through the rotation shaft 15; The first screw drive mechanism includes a first screw 13 and a first screw nut 14 matched with the first screw 13, wherein the swing motor 12 is rotatably connected to the first connecting block 11, and the swing motor The main shaft of 12 is connected with the first screw 13 , and the first screw nut 14 is rotatably connected with the second connecting block 10 . When the conveyer belt drives the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com