Stitching mechanism having piece counting function and used for woven bag stitching procedure

A technology of pressing mechanism and woven bag, which is applied in sewing equipment, sewing machine components, textiles and paper making, etc. It can solve problems such as accumulation of woven bags, failure to suture normally, easy deviation of suture opening, etc., so as to ensure consistency and convenience Check the effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

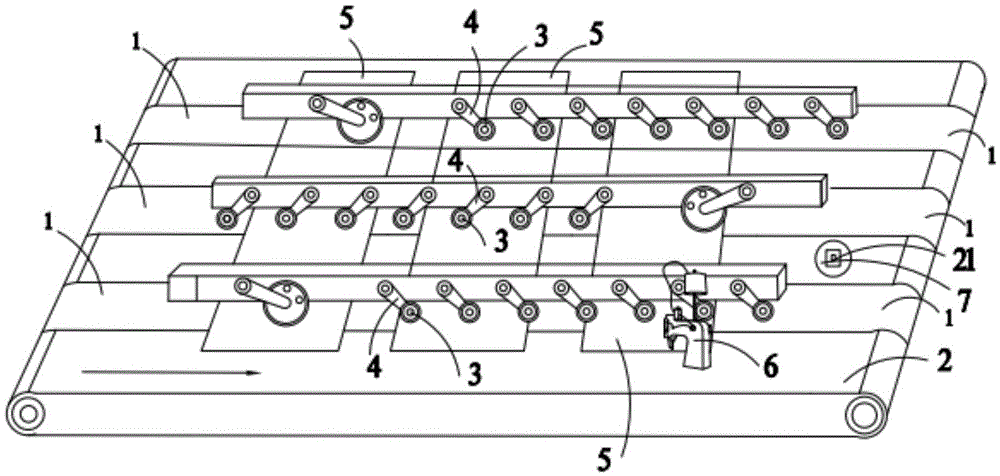

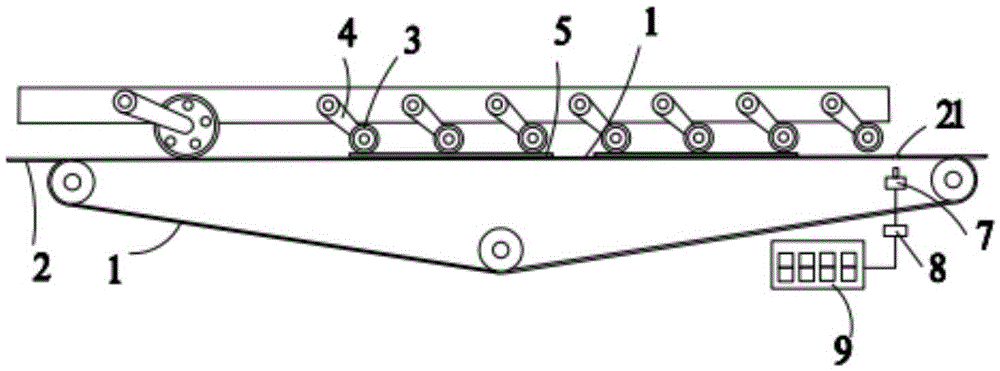

[0009] In the figure, 1 is a transmission belt, 2 is a support platform, 3 is a roller, 4 is a connecting arm, 5 is a woven bag, 6 is a sewing machine, 7 is a far-infrared sensor, 8 is a converter, 9 is a counter, and 21 is a through hole.

[0010] Depend on figure 1 It can be seen that the sewing and sealing process pressing mechanism of the woven bag 5 includes three transmission belts 1, a support platform 2 made of steel plates, a plurality of rollers 3, a far-infrared sensor 7, a converter 8 and a counter 9. An automatic sewing machine 6 is arranged on the support platform 2 . Three transmission belts 1 are horizontally arranged on the supporting platform 2 parallel to each other, and the transmission belts 1 are connected with the driving device for transmitting the woven bag 5 . The roller 3 is arranged above the transmission belt 1 and cooperates with the transmission belt 1 through the connecting arm 4 along the moving direction of the conveyor belt. Connecting arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com