Permanent lock bolt and method for using permanent lock bolt

A technology for anti-loosening bolts and bolts, applied in the direction of bolts, screws, nuts, etc., can solve the problems of machine vibration, damage to threaded fasteners, and failure to reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

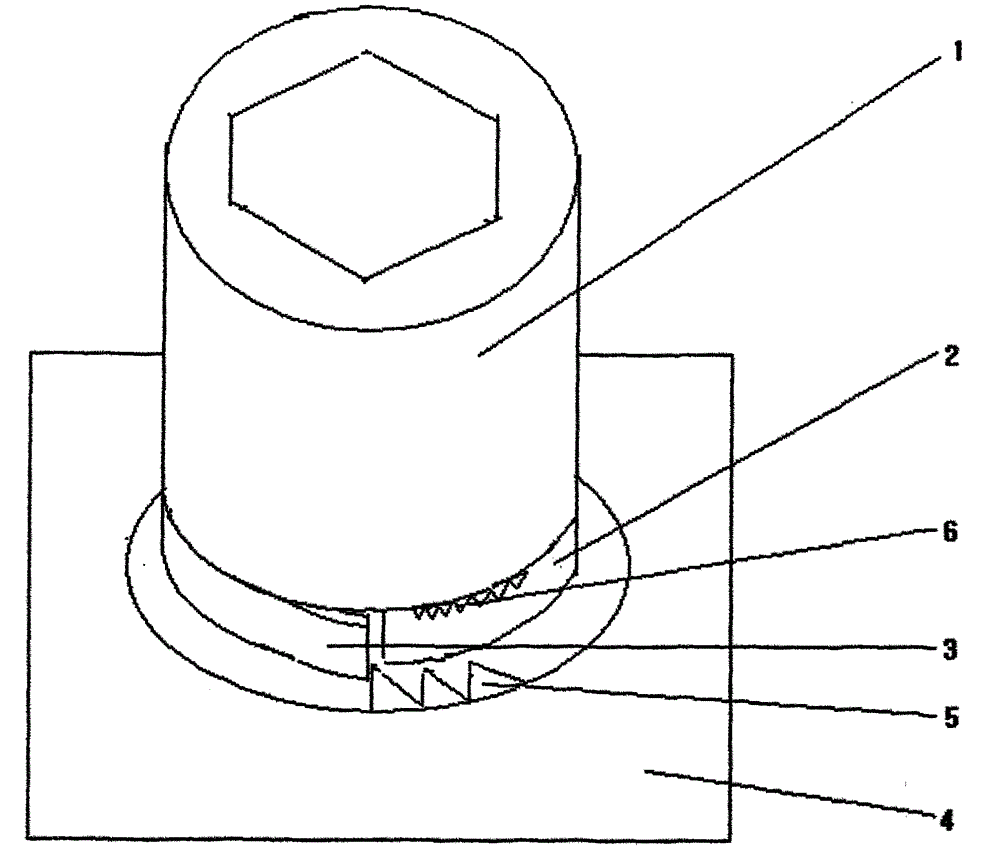

[0005] Screw the T-shaped bolt 1 in the clockwise direction on the screw hole of the machine part 4, set the C-shaped gasket 2 on the bolt, the gasket is made of spring steel, and the end 3 of the gasket pointing to the counterclockwise direction opens outwards. Serrations are provided on the surface of the gasket and the bottom surface of the head of the bolt respectively and engage with each other 6 . Serrations 5 are provided on the periphery of the screw hole outer end of the machine part, the tooth tips of the serrations face the direction of the screw hole, and the slopes of the serrations face the counterclockwise direction. The serrations on the face of the washer lock the head of the bolt, and the open end of the washer catches the serrations on the outer end of the screw hole. The elastic C-shaped gasket on the bolt can only rotate clockwise. When it rotates counterclockwise, the opened end of the C-shaped gasket will be stuck on the serrations at the outer end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com