Thread anti-loosening mechanism and anti-loosening mounting method

An installation method and thread technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of inability to quickly disassemble, inability to achieve anti-loosening, unreliability, etc., achieve reliable anti-loosening performance, prompt use flexibility, anti-loosening Reliable effect of loose measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manner of the present invention will be described in detail below according to the accompanying drawings.

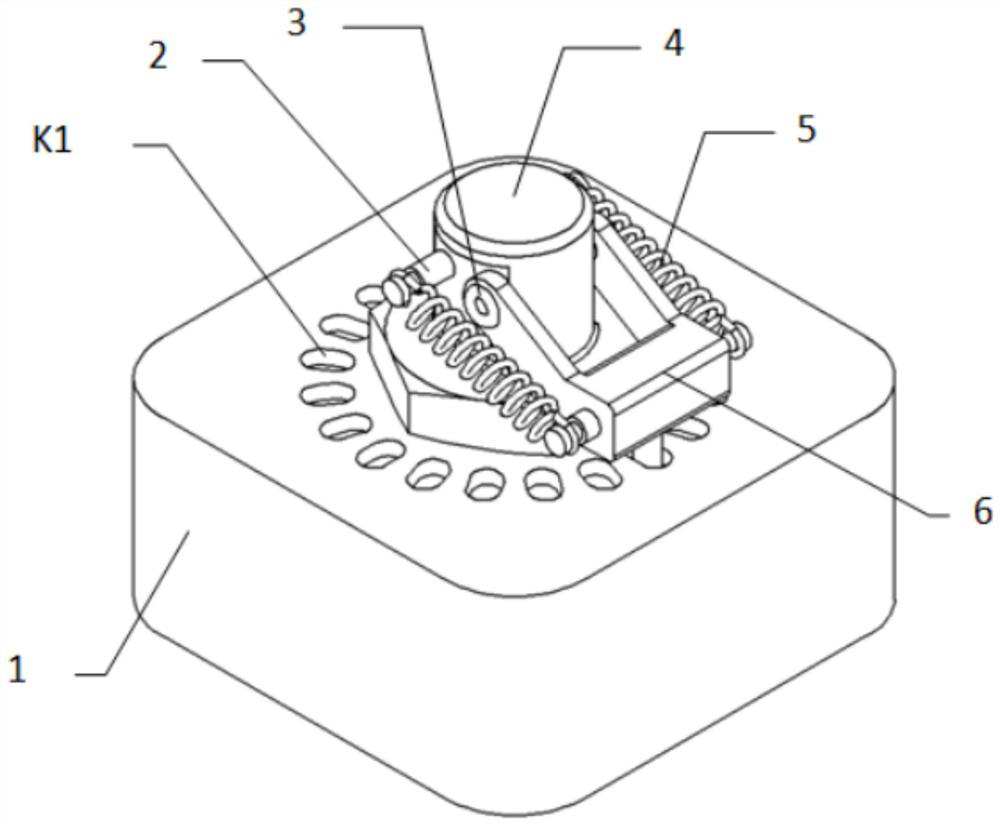

[0018] The overall design idea of the present invention is to provide a fast-detachable thread anti-loosening mechanism by utilizing the spring fixed limit mechanism to carry out the thread anti-loosening and the design idea of rotating past the dead point for quick disassembly. A concrete realization of a thread anti-loosening mechanism, the structural diagram is as follows figure 1 As shown, it is mainly composed of mounting base 1; pin shaft 2; hollow rivet 3; screw rod 4; On the mounting base 1, the upper surface of the mounting base 1 is provided with a circle of small holes K1 for inserting the rotating arm 6;

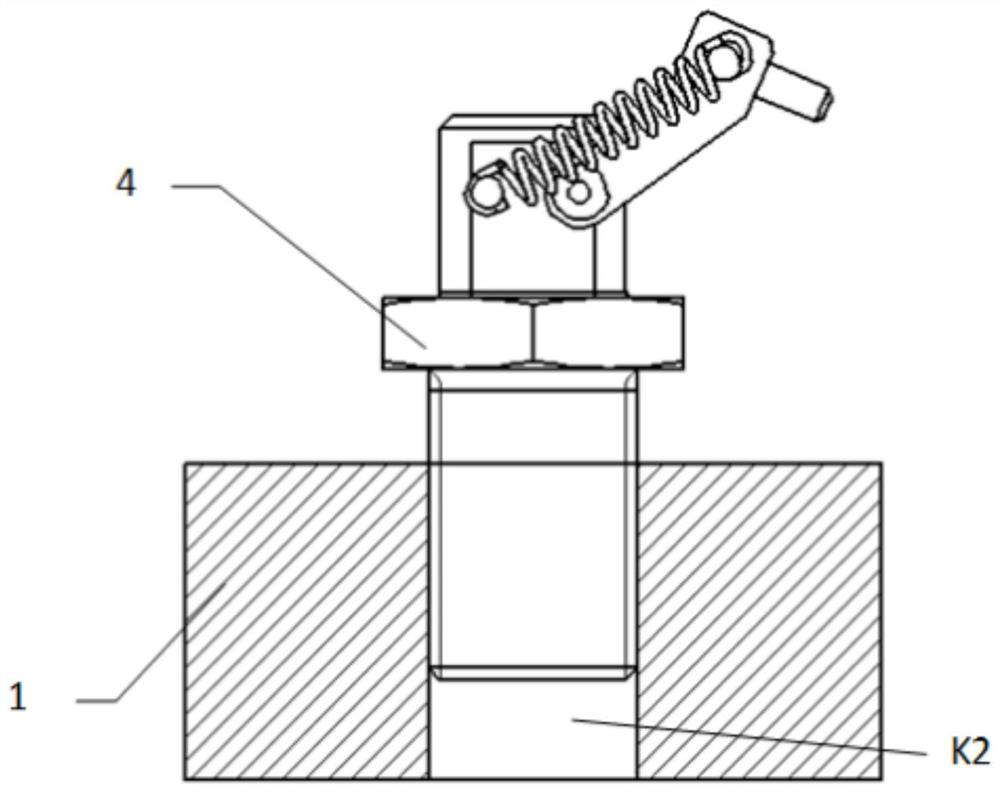

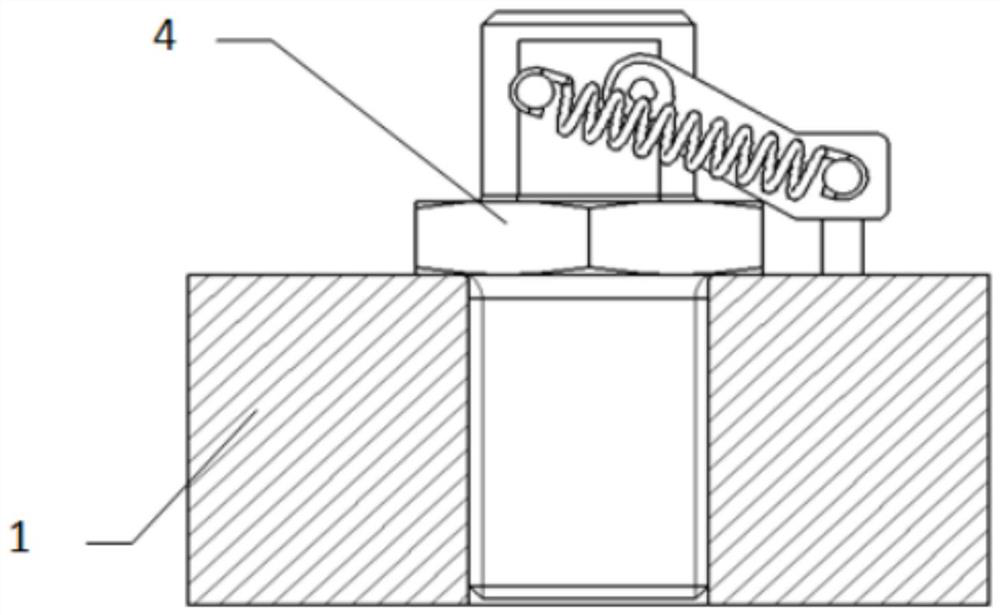

[0019] The screw 4 is in the shape of large and small steps, and the bottom of the screw 4 is provided with an external thread for connecting with the threaded hole K2; the middle of the screw is provided with an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com