Clamping bracket to hold flashlight

A technology for clamping brackets and flashlights, which is applied to the components of lighting devices, lighting auxiliary devices, lighting and heating equipment, etc., can solve the problems of complex bracket structure, poor versatility, and low reliability, and achieve convenient use and simple structure , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

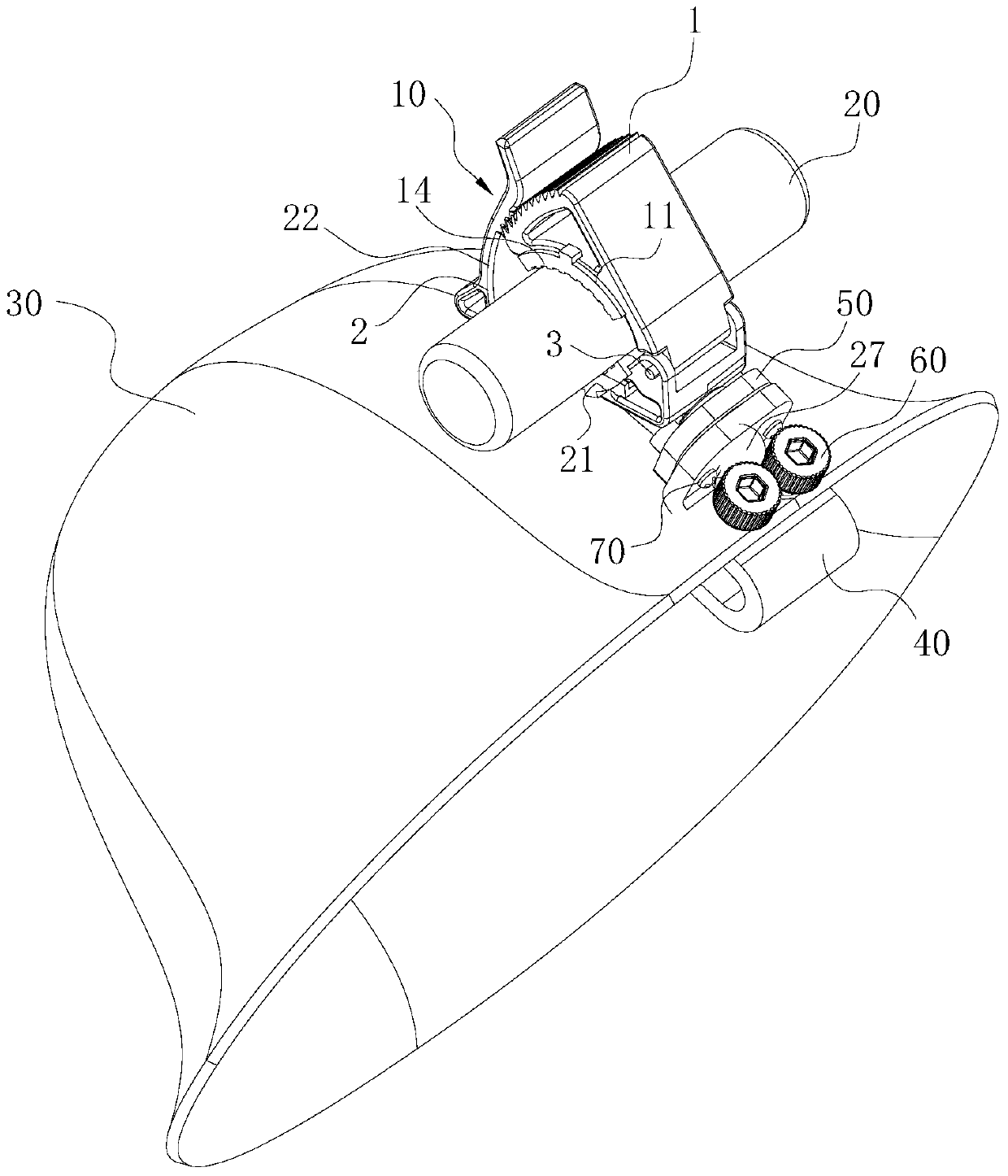

[0018] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

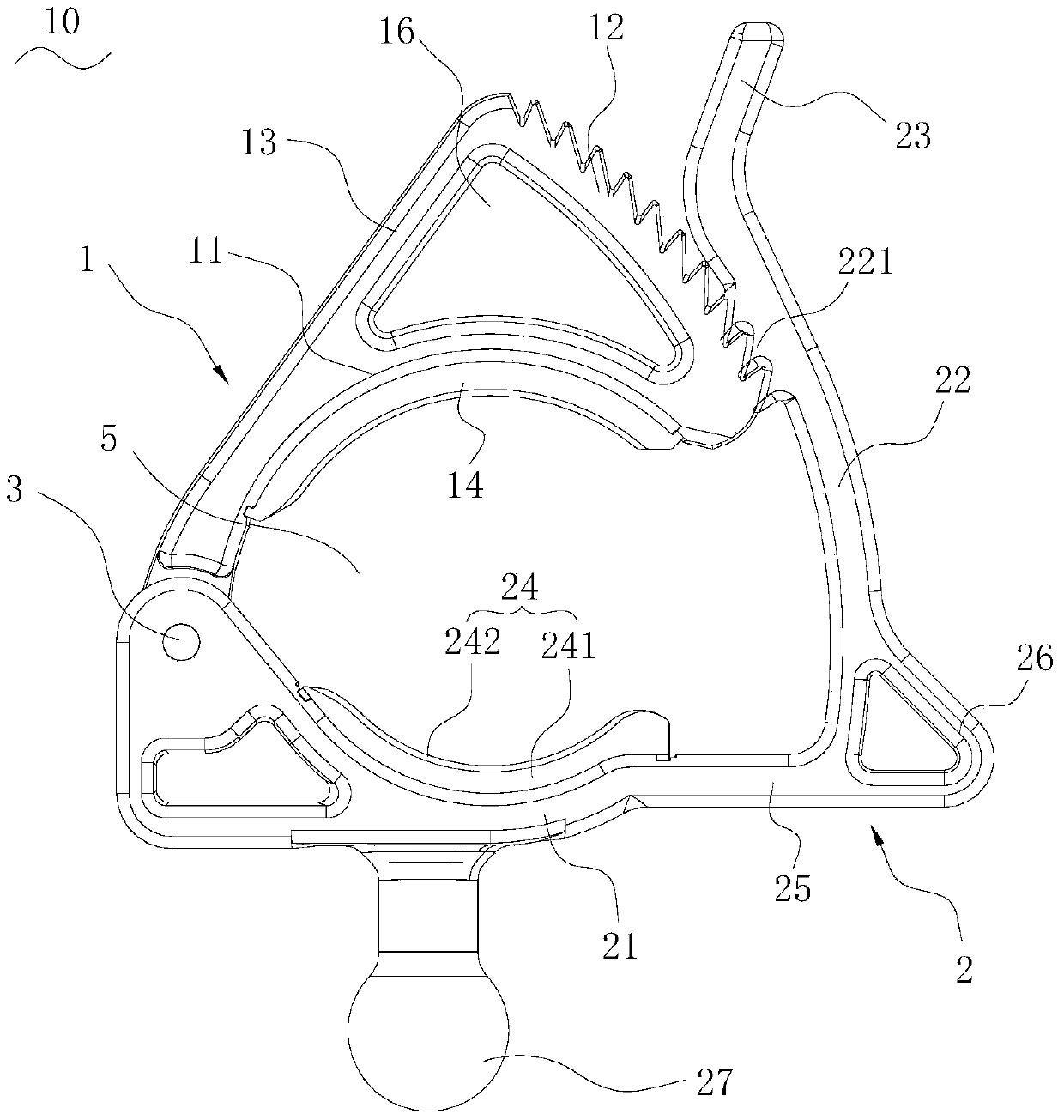

[0019] The invention provides a clamping bracket capable of clamping flashlights with different diameters. Through the cooperation of three main parts, a variable-diameter clamping bracket mechanism with a large adjustable range is formed.

[0020] figure 1 A clamping bracket structure of a preferred embodiment of the present invention is illustrated, and the clamping bracket 10 includes three main parts: a first clamping arm 1 , a second clamping arm 2 and a rotating shaft 3 . The first clamping arm 1 and the second clamping arm 2 realize mutual rotation through the rotating shaft 3, thereby forming a variable-sized clamping space 5 between the first clamping arm 1 and the second clamping arm 2, so that It can clamp flashlights of different diameters.

[0021]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com