Valve Stem Booster

A technology of booster and valve stem, applied in valve details, valve device, valve operation/release device, etc., can solve problems such as hidden danger of industrial valve safety use, device slippage, valve handwheel and external device fixed connection, etc. Solve the effect of assisting the opening of damaged valves and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

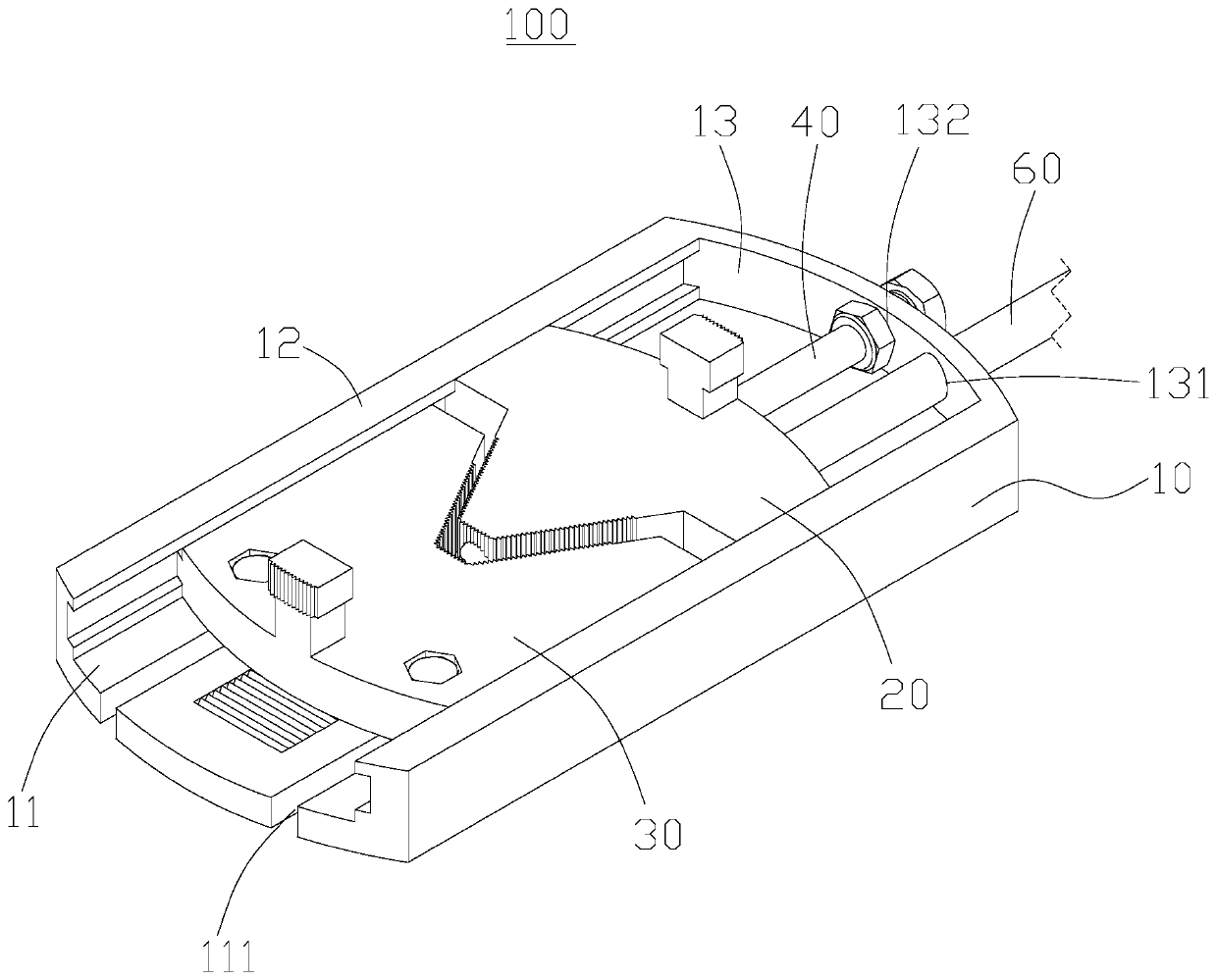

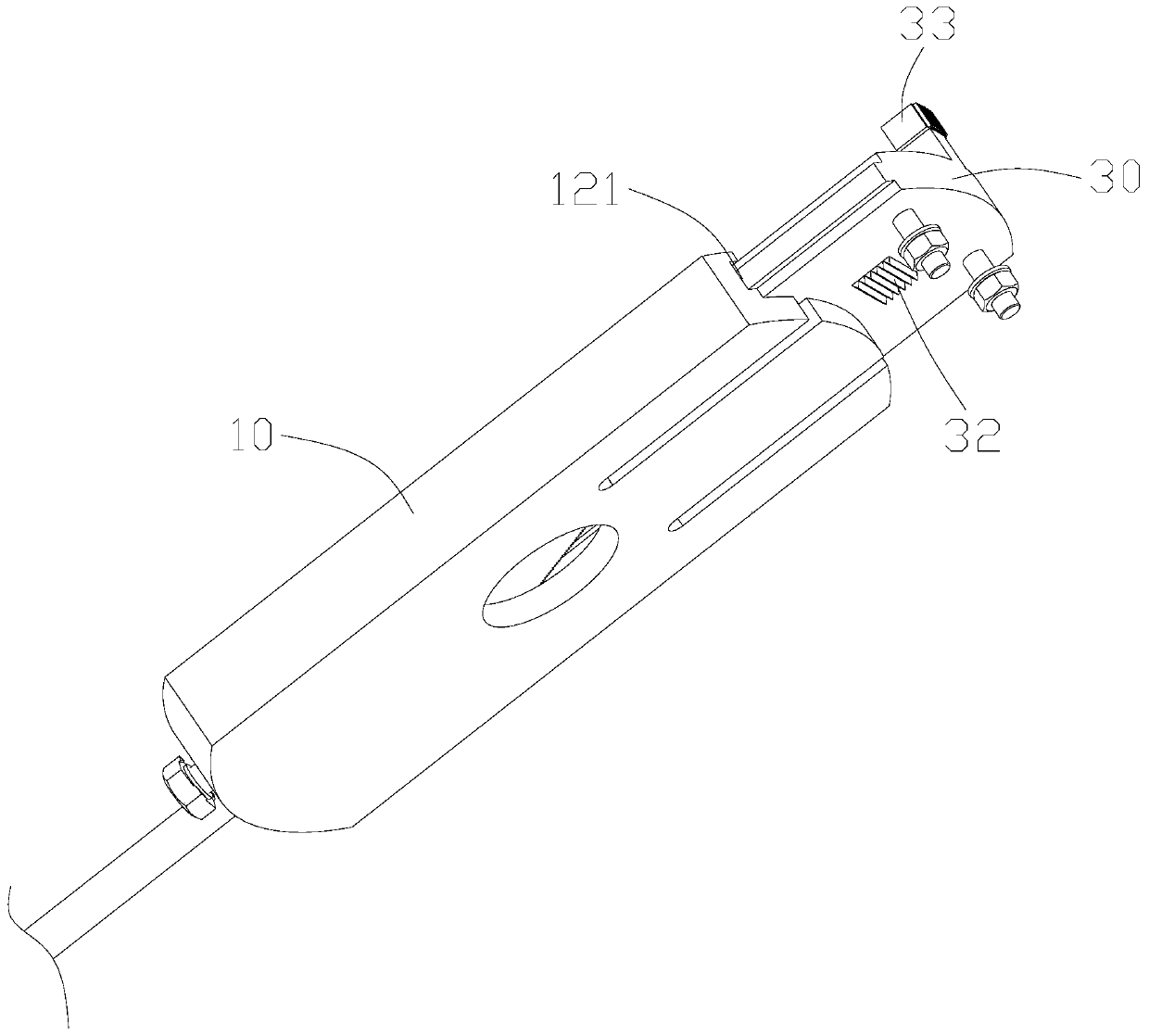

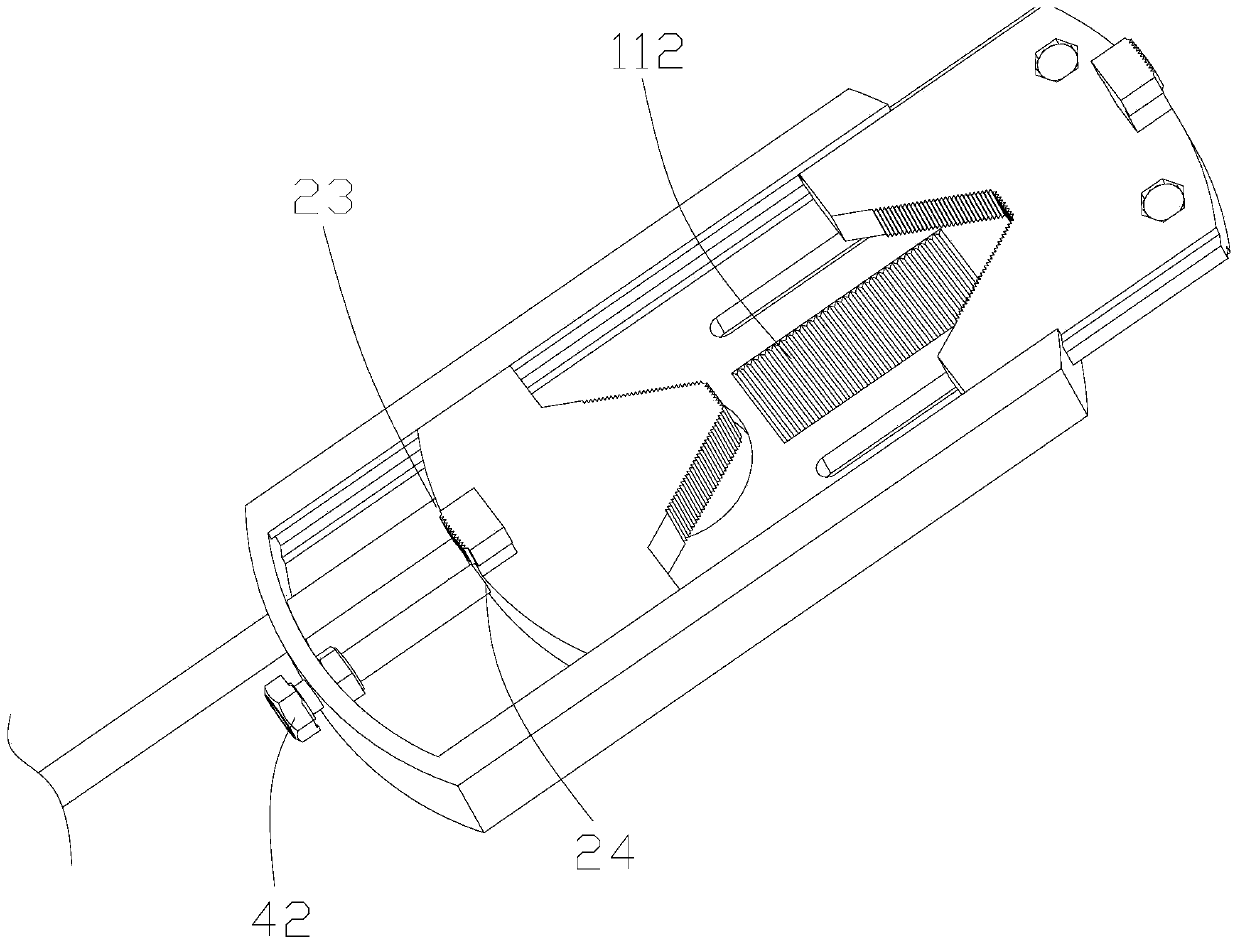

[0028] like Figure 1-4 As shown, it is a valve stem booster 100 of a preferred embodiment of the present invention, including a housing 10, a first fixing member 20, a second fixing member 30 and a booster rod 60, the housing 10 includes a bottom plate 11, and the first fixing member The piece 20 and the second fixing piece 30 are slidably installed on the bottom plate 11 in turn, and the first fixing piece 20 and the second fixing piece 30 are respectively provided with first clamping teeth 21 and second clamping teeth 31 with matching shapes on opposite sides of the second fixing piece 30. A clamping tooth 21 and a second clamping tooth 31 cooperate to clamp the valve stem 301; the housing 10 is provided with a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com