Slim Ironless Brushless Two Pole Permanent Magnet DC Motor

A permanent magnet direct current, slender technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems that the motor fails to achieve the maximum efficiency, maximizes the efficiency of the motor, and does not highlight the maximum efficiency of the motor. The effect of small loss, high power density, and maximized motor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

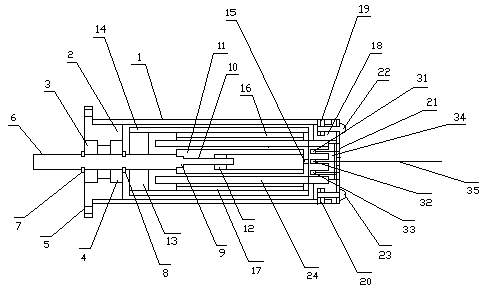

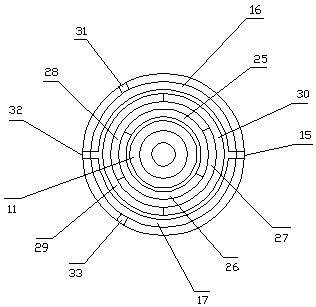

[0014] exist figure 1 , figure 2, middle, the barrel-shaped shell 1 is made of non-magnetic aluminum alloy, the inner circle of the left end of the barrel-shaped shell is tightly fitted with the left end cover 2, the inner circle of the left end cover is provided with a bearing frame, and the inner circles of the left and right ends of the bearing frame are installed with left and right Bearings 3 and 4, the left end of the left end cover is formed with a square flange, and the four corners of the flange are provided with connecting holes 5, and the inner and outer rotors are provided with drive shafts 6, which are installed on the inner circles of the left and right bearings, and are located at the left and right ends of the left bearing. The outer circle of the drive shaft at the right end of the bearing is formed with left and right circlip grooves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com