Rotary compressor assembly and air conditioner having same

A rotary compressor and compressor technology, applied in rotary piston machinery, rotary piston/oscillating piston pump components, machines/engines, etc., can solve the problem of reducing compressor energy efficiency, small pressure ratio, large pressure ratio, etc. problems, to achieve the effect of improving efficiency and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

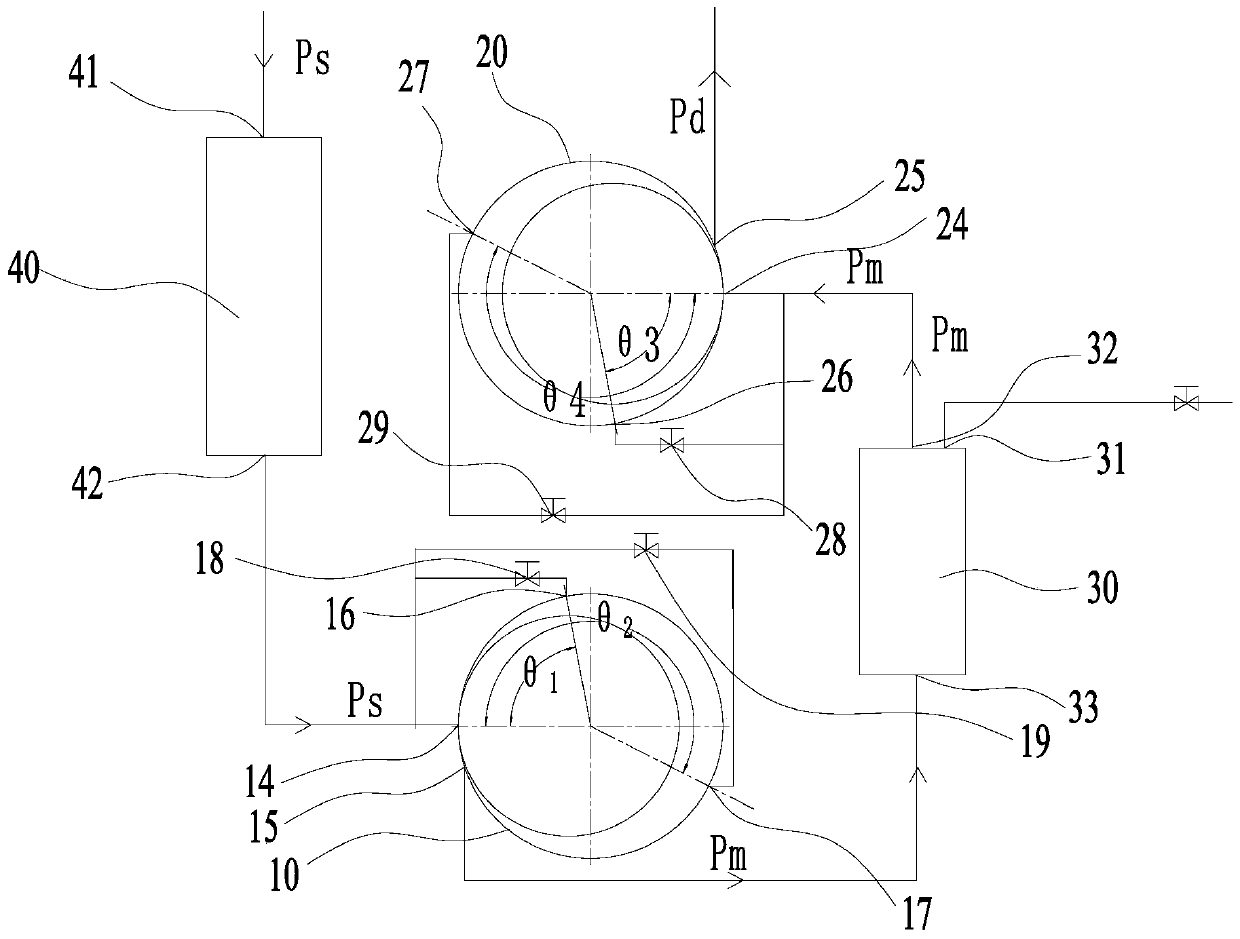

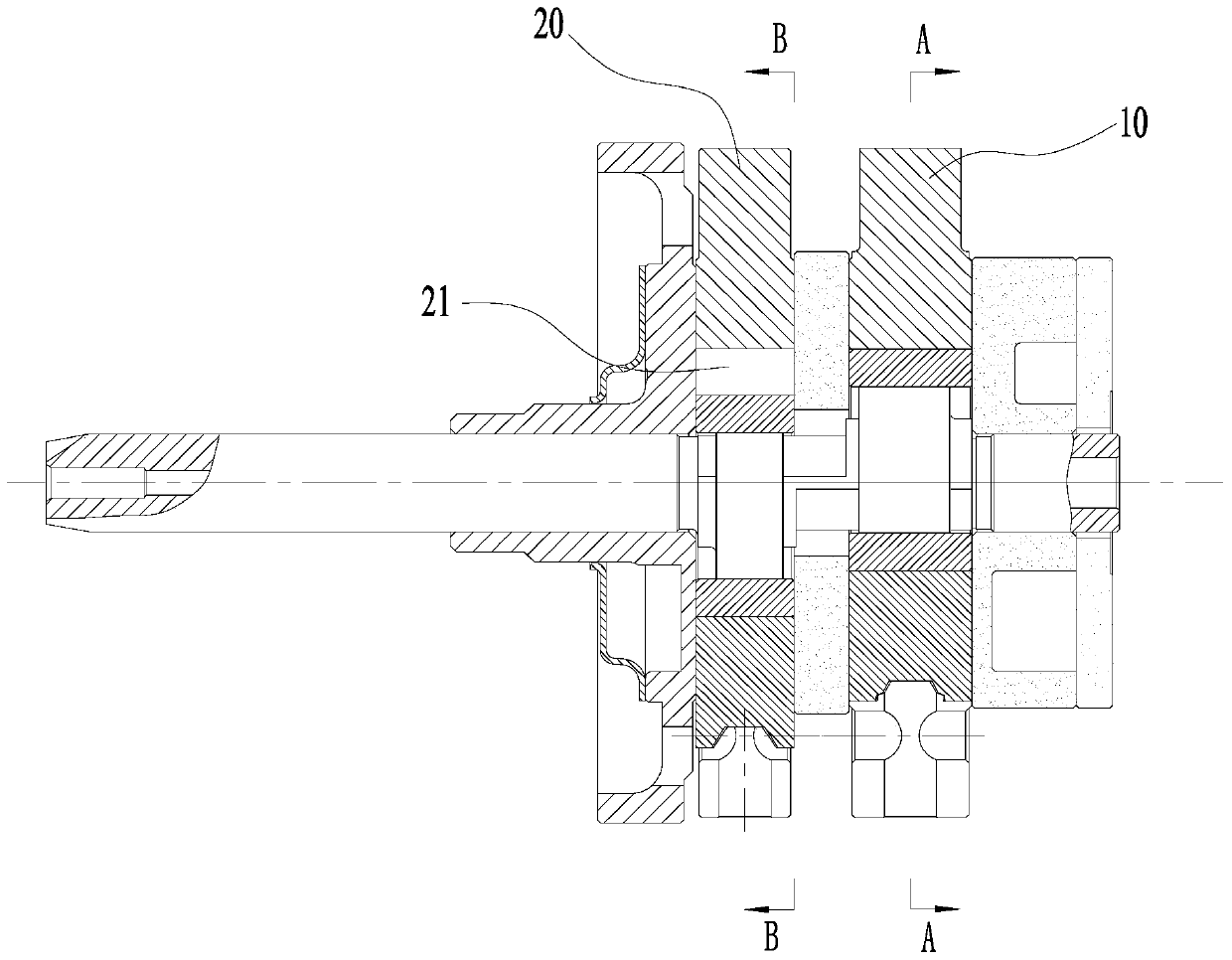

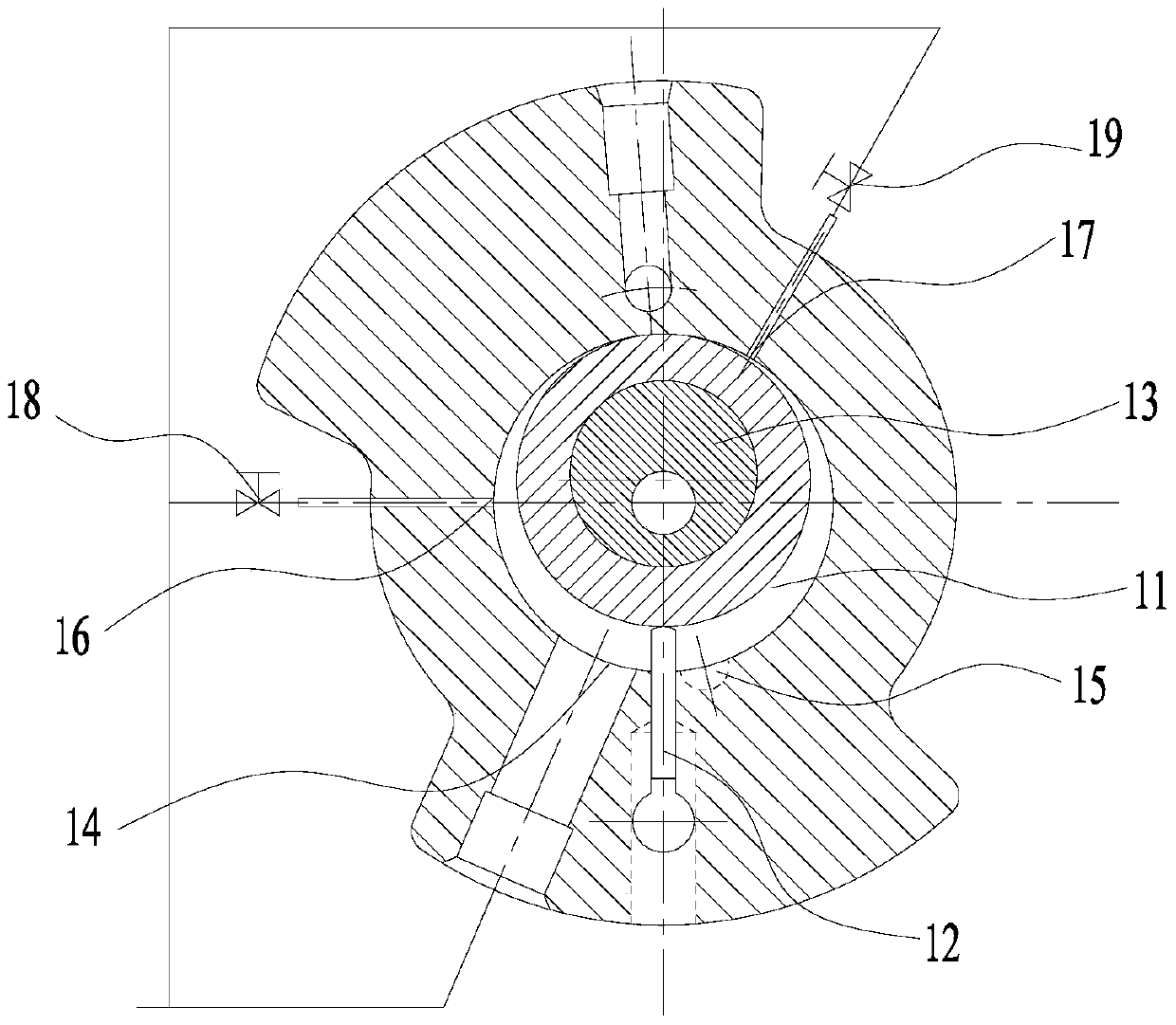

[0023] Such as Figure 1 to Figure 4 As shown, the rotary compressor assembly of this embodiment includes a compressor body, and the compressor body includes a first compression cylinder 10 and a second compression cylinder 20 . The first compression cylinder 10 includes a first compression chamber 11, a first slide plate 12, and a first rotor 13. The first compression chamber 11 has a first suction port 14 and a first exhaust port 15. When the first rotor 13 rotates Directionally, the first suction port 14 is located behind the first slide 12 and the first exhaust port 15 is located behind the first suction port 14 . The second compression cylinder 20 includes a second compression chamber 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com