Two-stroke engine

An engine, two-stroke technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as large design space, and achieve the effects of simple structure, high cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

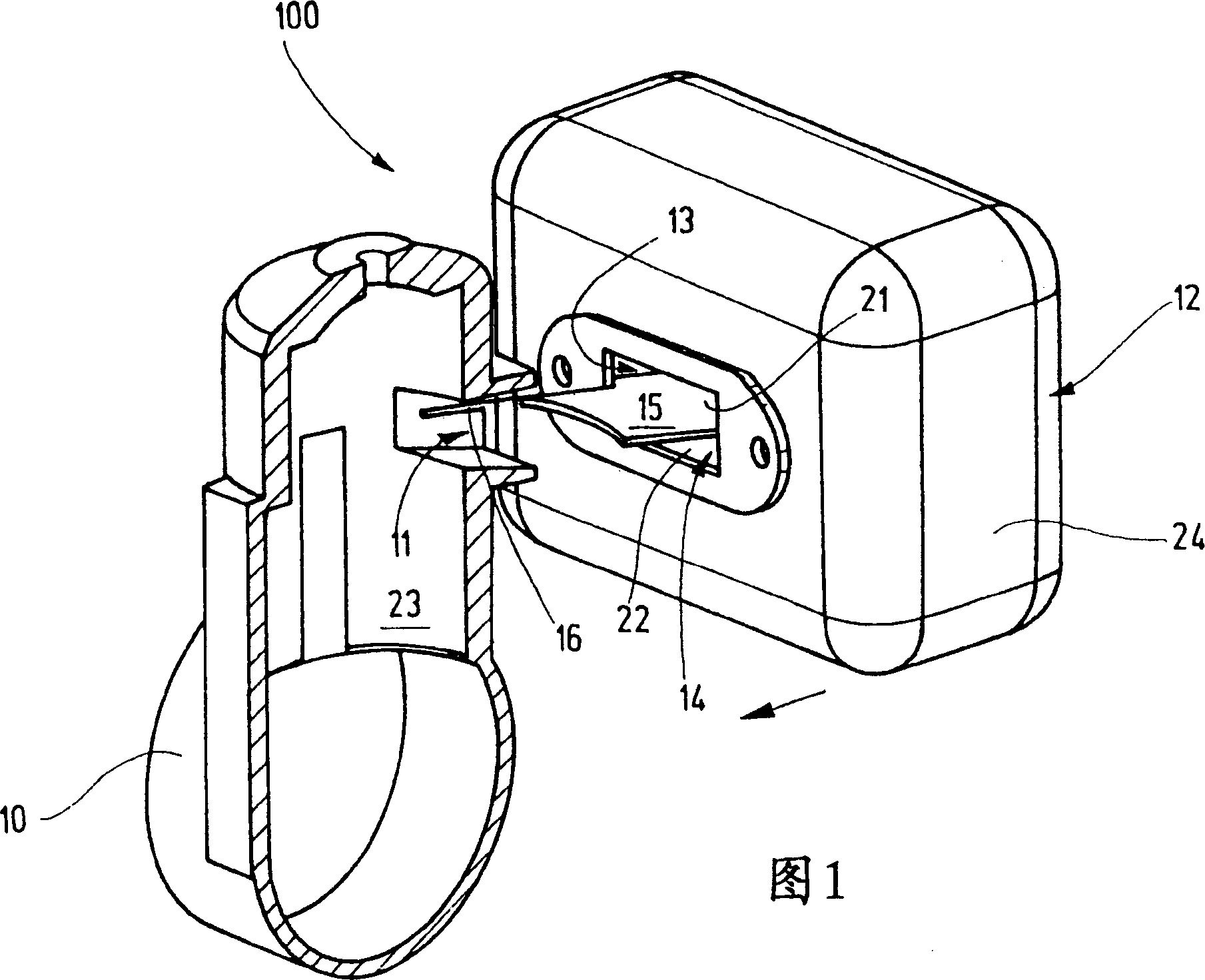

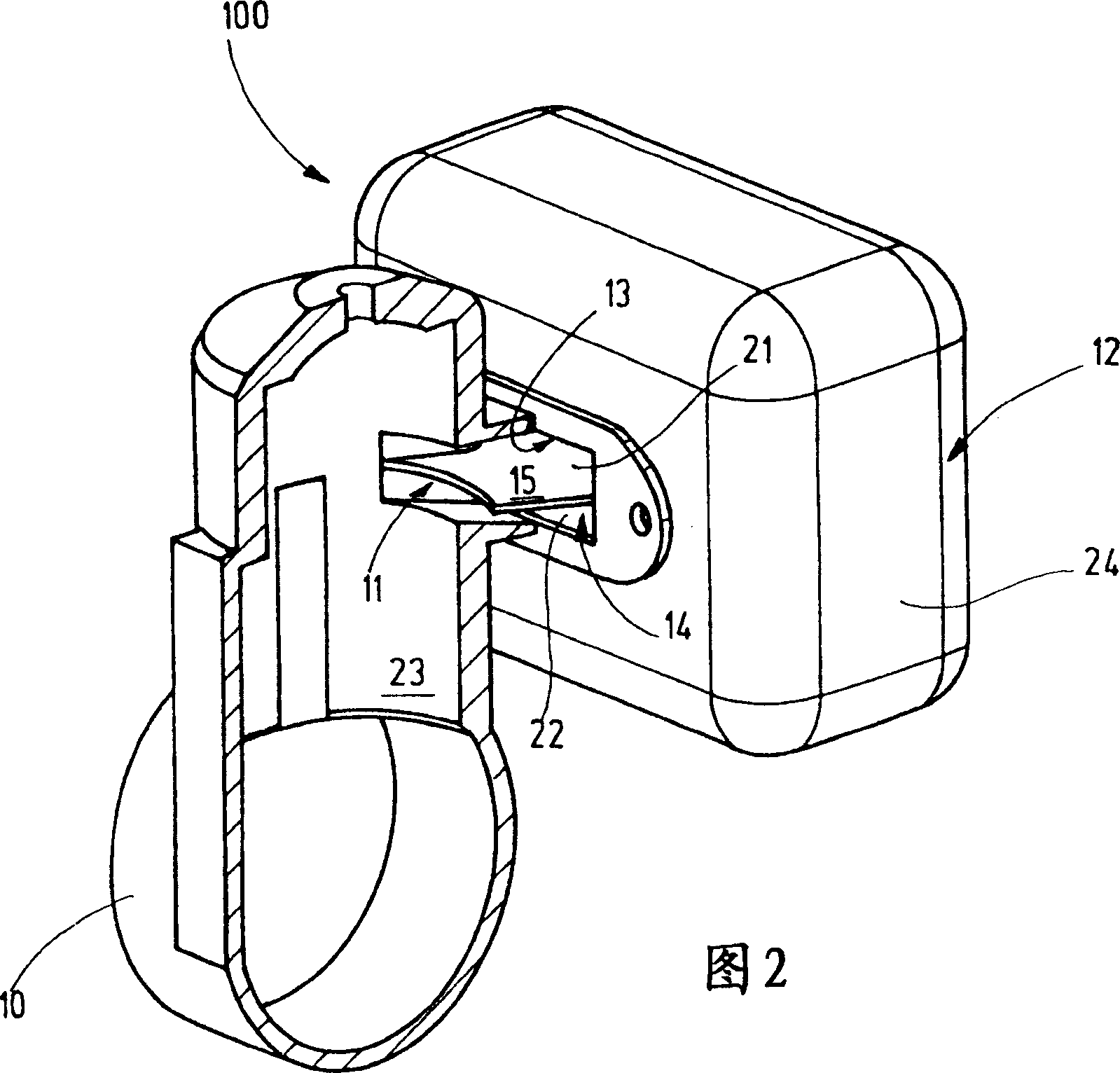

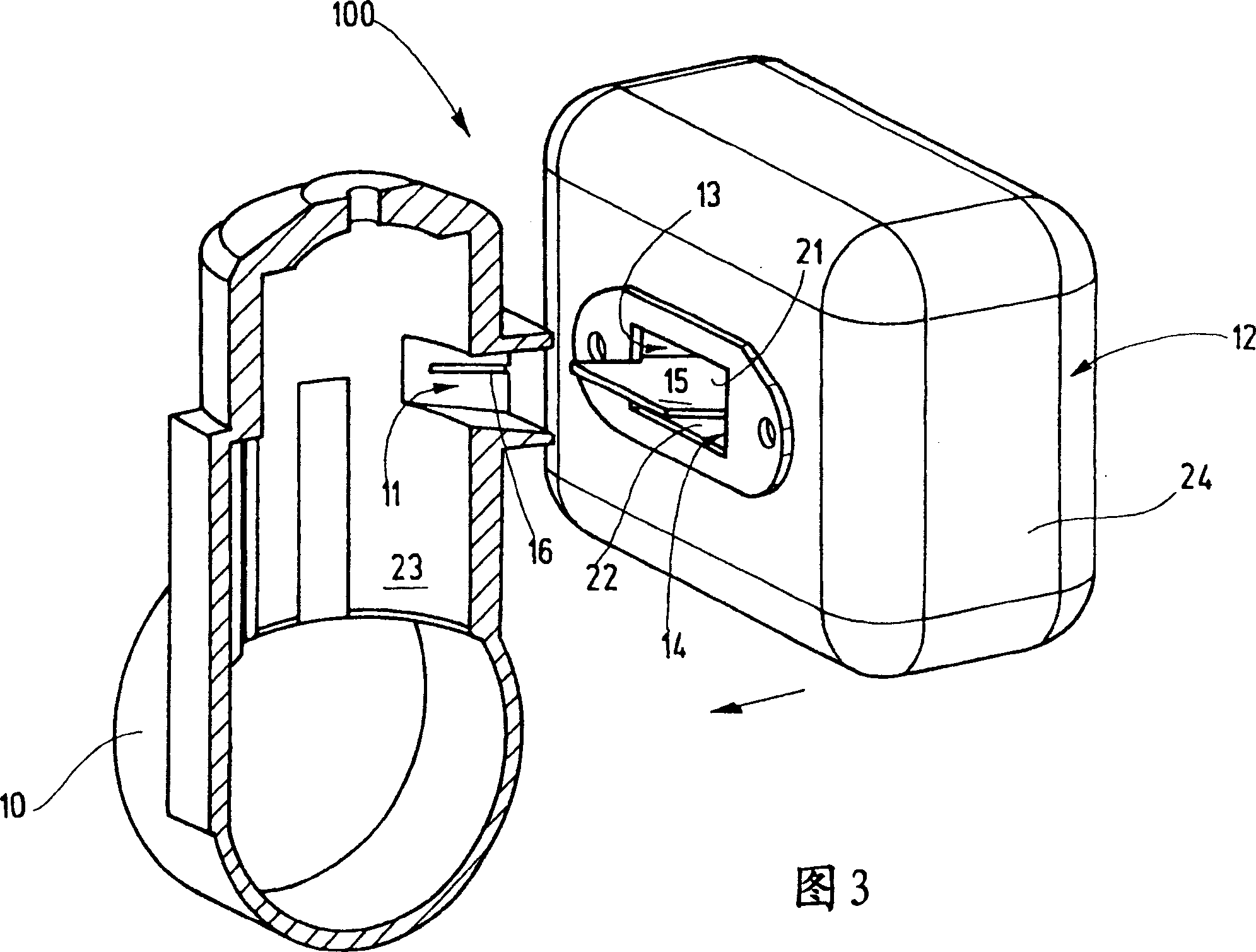

[0037]Figure 1 shows a cylinder 10 of a two-stroke engine 100 having a working volume 23 in which the piston moves and having an exhaust outlet 11 in the form of a duct. The lateral duct wall has fastening means 126 in the form of two grooves 16 (only one groove 16 is shown because it is shown in section), wherein the grooves 16 end at a certain distance from the working volume 23 . Mounted on the cylinder 10 is a muffler 12 having a first chamber 13 and a second chamber 14 surrounded by a common housing wall 24 . The first chamber 13 and the second chamber 14 are separated from each other by a wall, not shown, located inside the housing wall 24 . A bypass is provided between the two chambers, also not shown. The muffler 12 has an inlet which is divided by a partition 15 , thus forming an upper opening 21 and a lower opening 22 . The upper opening 21 is connected to the first chamber 13 as a buffer chamber, and the lower opening 22 is connected to the second chamber 14 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com