Gear with hobbed hard tooth surface

A hard tooth surface and hobbing technology, which is applied to components with teeth, gear lubrication/cooling, belts/chains/gears, etc., can solve problems such as misinstallation, affecting the fixing effect, and waste of lubricating oil, so as to save lubrication oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

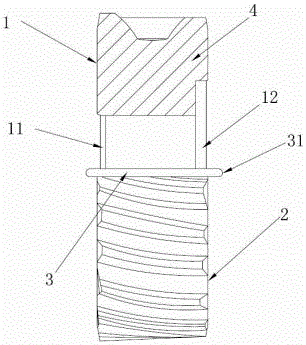

[0011] like figure 1 As shown, it includes a gear rod 1 and a gear body 2, and a transverse stopper 3 is provided between the gear rod 1 and the gear body 2, which can effectively prevent the lubricating oil on the gear body 2 from flowing into the gear rod, causing the gear rod 1 Loosening, while saving lubricating oil to a certain extent, the edge of the retainer 3 is arc-shaped 31, the left side of the gear rod 1 is provided with a small keyway 11, the right side of the gear rod 1 is provided with a large keyway 12, the The small keyway 11 is located on the corresponding surface of the large keyway 12. The large keyway 12 and the small keyway 11 are not only used to fix other structures, but also play a positioning role to prevent misinstallation. The gear rod 1 and the gear body 2 are equipped with The wear-resistant layer 4, the gear body 2 is a helical gear, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com