An instrument pointer shaft detection device

A technology of detection device and instrument pointer, applied in the direction of angle/taper measurement, etc., can solve the problems of large error, inaccuracy, fuzzy detection results, etc., and achieve the effect of eliminating manual operation errors, accurate detection results, and rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

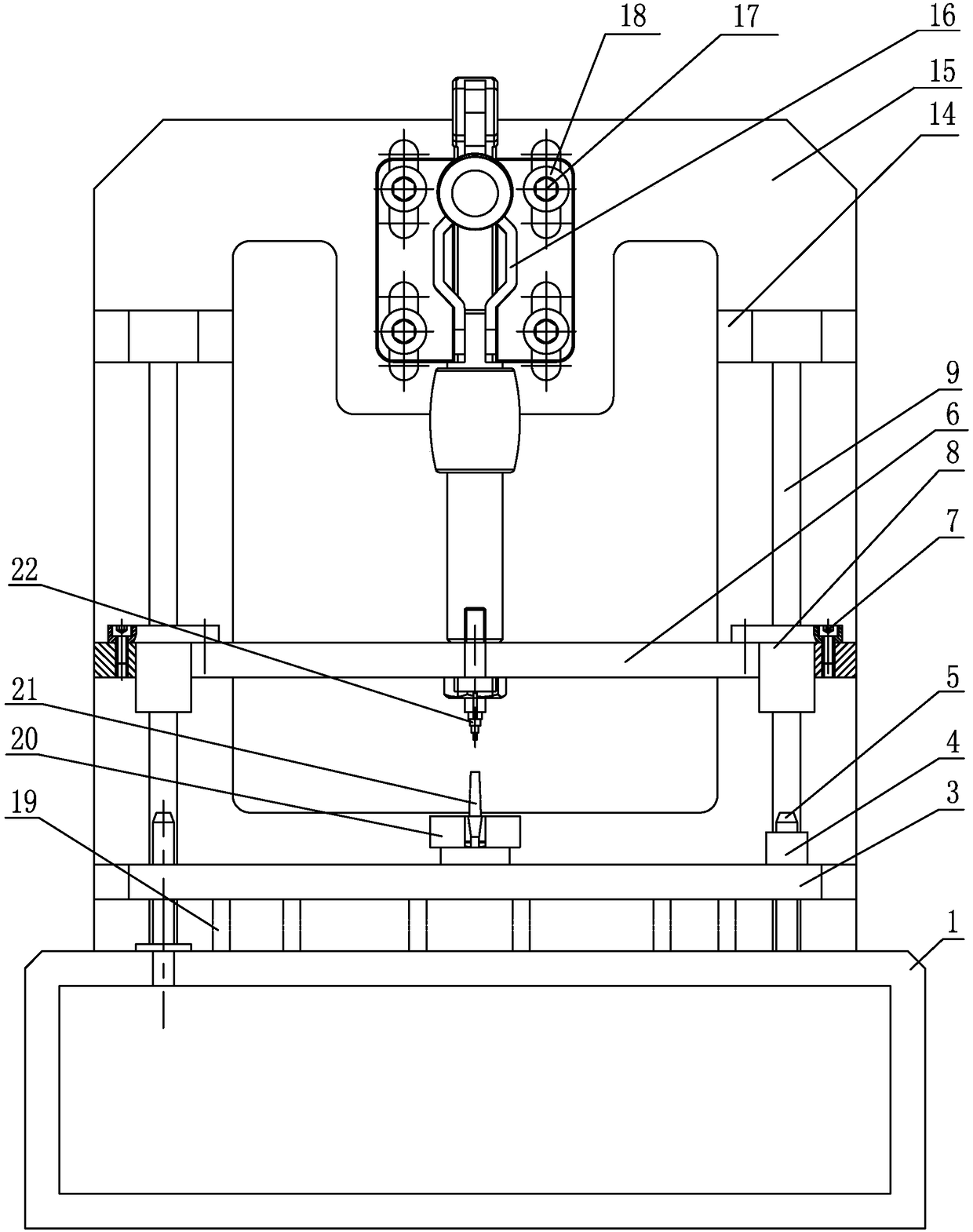

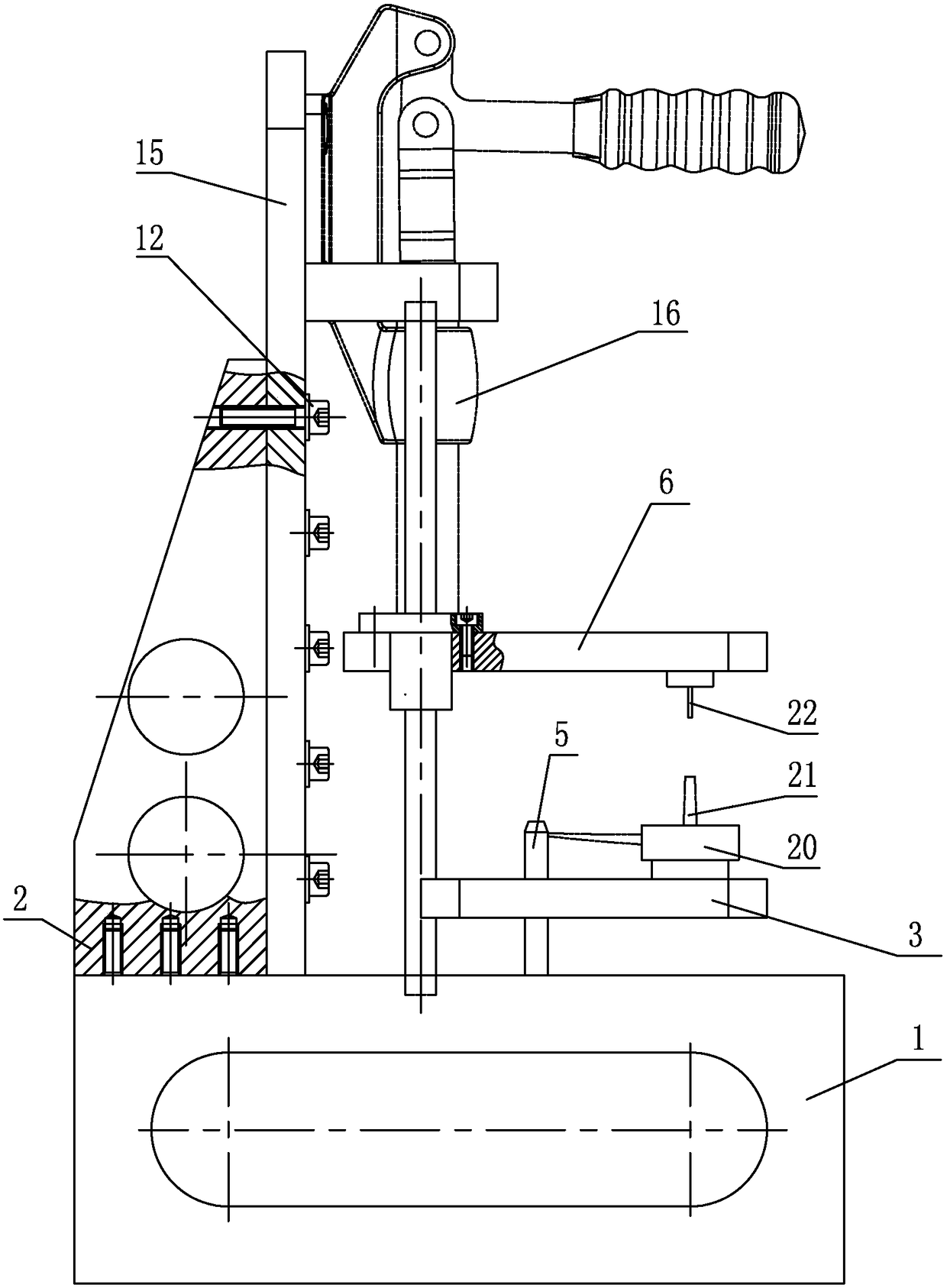

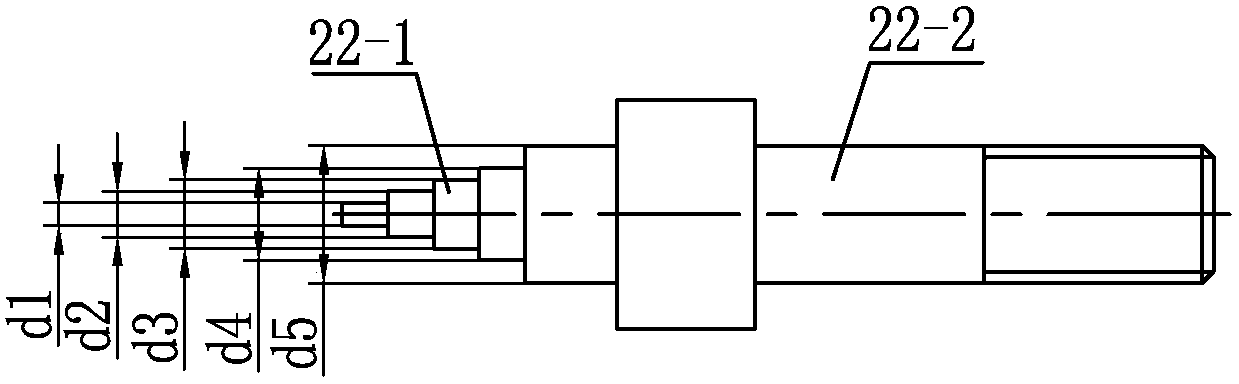

[0012] Specific implementation mode one: combine Figure 1-Figure 5 Explain that a meter pointer shaft detection device in this embodiment includes a base 1, a pointer plate 3, a probe plate 6, a vertical plate 15, a quick clamp 16, a pointer fixing seat 20, two guide columns 9, two An upper linear bearing 8 and two lower linear bearings 4;

[0013] The base 1 is fixed with a vertical plate 15, two guide columns 9 are arranged side by side and installed vertically on the base 1, a lower linear bearing 4 is installed on the lower end of each guide column 9, and the pointer plate 3 is installed on the two lower linear bearings. On the bearing 4, a pointer holder 20 capable of circumferential rotation is installed on the pointer plate 3, the pointer cap of the pointer 21 is installed on the pointer holder 20, and two guide posts 9 above the two lower linear bearings 4 are installed with Two upper linear bearings 8, the probe board 6 is installed on the two upper linear bearings ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 1 Note that the instrument pointer shaft detection device of this embodiment also includes two positioning pins 5, two positioning pins 5 and two guide columns 9 are arranged side by side, the positioning pins 5 are installed on the base 1, and the positioning pins 5 pass through the pointer plate 3 and the two are in sliding contact. With such arrangement, the positioning pins ensure the parallelism and perpendicularity between the base 1 and the pointer plate 3 and at the same time enable the pointer plate 3 to slide freely up and down. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 It should be noted that the instrument pointer shaft detection device of this embodiment further includes a plurality of compression springs 19 , and a plurality of compression springs 19 are arranged between the pointer plate 3 and the base 1 and connected to both. The buffer spring provides buffer protection when the pointer shaft 22 is detected. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com