A heat treatment experimental device

The technology of an experimental device and a furnace body, which is applied in the field of heat treatment experimental devices, can solve problems such as the influence of operating speed on test accuracy, and achieve the effects of improving test accuracy and test efficiency, stable performance, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

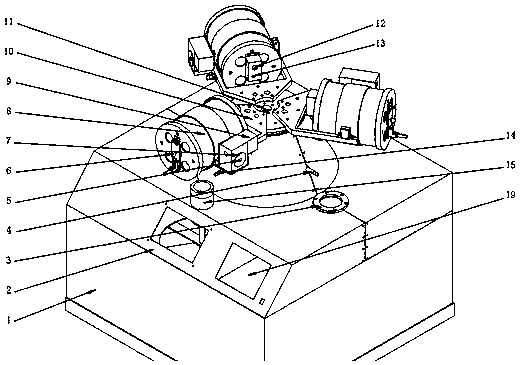

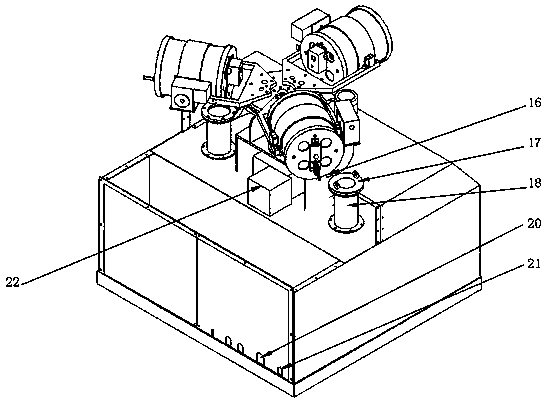

[0030] The heat treatment experimental device in this embodiment includes a cooling water tank 1, a body 2, a water quenching net 3, a furnace shaft 5, a furnace door 6, a turbine worm 7, a furnace body 8, a furnace body motor 9, a furnace body bracket 10, and a main shaft 11. Protective atmosphere inlet 12, thermocouple inlet 13, end quenching sample holder 15, oil quenching net bag 17, quenching oil pool 18, controller 19, cooling water inlet 20, cooling water outlet 21, furnace body support motor 22; body 2 is provided with a cooling water tank 1 underneath the body 2, a furnace body support motor 22 and a turbine reducer are provided on the upper surface of the body 2, the furnace body support motor 22 is connected to the turbine reducer, the output shaft of the turbine reducer is connected to the main shaft 11, and the main shaft 11 passes The flange is connected to the furnace body bracket 10; the furnace body bracket 10 is connected to the furnace body shaft 5 through the...

Embodiment approach 1

[0039] The device described in this embodiment is used for water quenching operation:

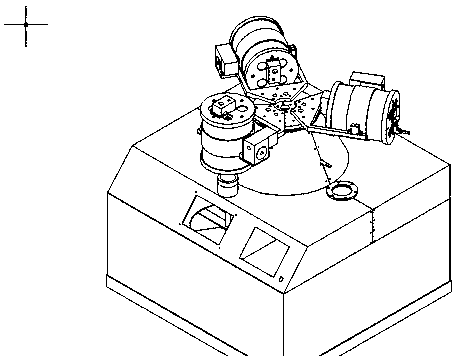

[0040] Load the sample, pass in the protective atmosphere, and heat up the furnace body 8. When it reaches the set temperature, heat preservation is performed. After the heat preservation is completed, the furnace body support motor 22 drives the main shaft 11 to rotate the furnace body 8 to the water quenching station. The furnace body motor 9 drives the furnace body 8 to rotate down 90 degrees. At this time, the furnace door is opened, and the sample automatically falls into the water quenching net 3 to complete the quenching process, and then the furnace body motor 9 drives the furnace body 8 to rotate 90 degrees in reverse. Return the furnace body 8 to its original position to complete the water quenching process (such as Figure 4 Shown).

Embodiment approach 2

[0042] The device described in this embodiment is used for oil quenching operations:

[0043] Load the sample, pass in the protective atmosphere, and heat up the furnace body 8. When the set temperature is reached, heat preservation is performed. After the heat preservation is completed, the furnace body support motor 22 drives the main shaft 11 to rotate the furnace body 8 to the oil quenching station. The furnace body motor 9 drives the furnace body 8 to rotate 90 degrees downwards. At this time, the furnace door is opened, and the sample automatically falls into the quenching oil pool 18 to complete the quenching process, and then the furnace body motor 9 drives the furnace body 8 to rotate 90 degrees in reverse. Return the furnace body 8 to its original position to complete the oil quenching process (such as Figure 5 Shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com