Crochet hook anti-swing structure

An anti-swing and crochet needle technology, which is applied to the loop mechanism of sewing machines, textiles, papermaking, sewing equipment, etc. It can solve the problems of poor waist pulling effect, crochet needles swinging and skipping under force, etc., so as to achieve convenient operation and use, and avoid skipping stitches , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

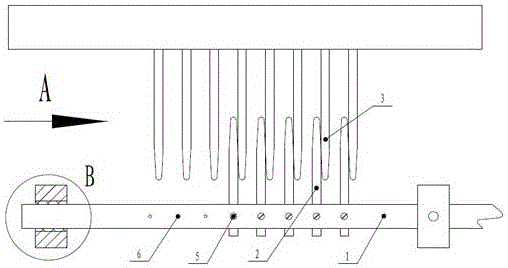

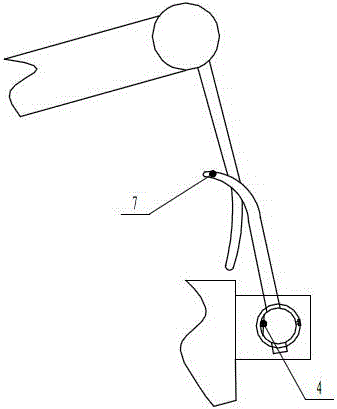

[0016] Such as Figure 1~3 As shown, a crochet anti-swing structure includes a fixed rod 1 fixedly connected to the machine base 9, a plurality of arc-shaped anti-sway rods 2 are arranged on the fixed rod 1, and the free ends of the anti-sway rods 2 are bent downwards. Stretch to one side of the crochet needle 3, close to the side of the crochet needle 3.

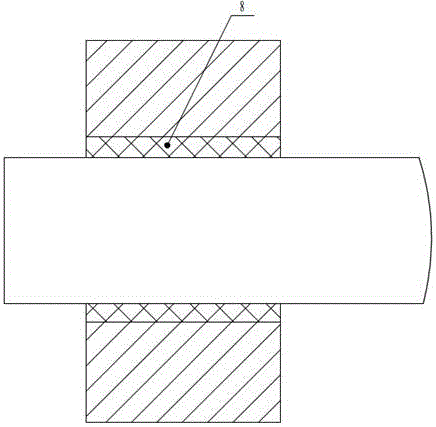

[0017] Preferably, the bottom end of the above-mentioned fixed rod 1 is provided with a strip-shaped plane 4, the length of which is greater than the total width of a row of crochet needles 3, and a strip-shaped plane is provided so that when the crochet needle rotates, it will not bump into the fixed rod. Improve the service life of crochet hooks.

[0018] Preferably, the above-mentioned anti-sway bar 2 is connected to the installation hole 6 provided on the fixed rod 1 through a set screw 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com