Matching accuracy tester for auto parts

A technology for precision detection and auto parts, which is applied in the direction of instruments, measuring devices, mechanical diameter measurement, etc., can solve the problems of time-consuming detection, increase the difficulty of detection, and reading errors, etc. It is convenient to achieve radius, ensure high-precision detection, and convenient detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

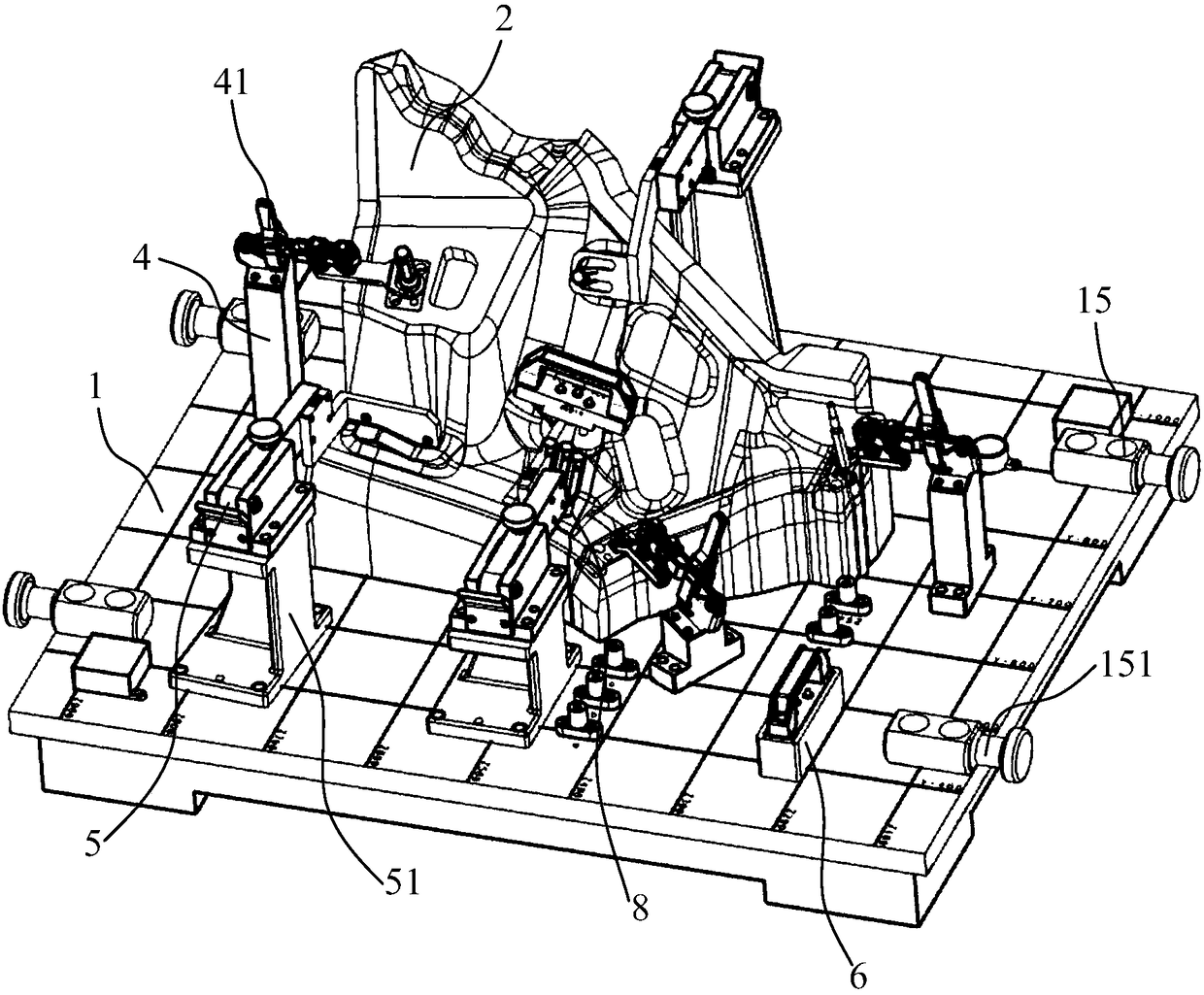

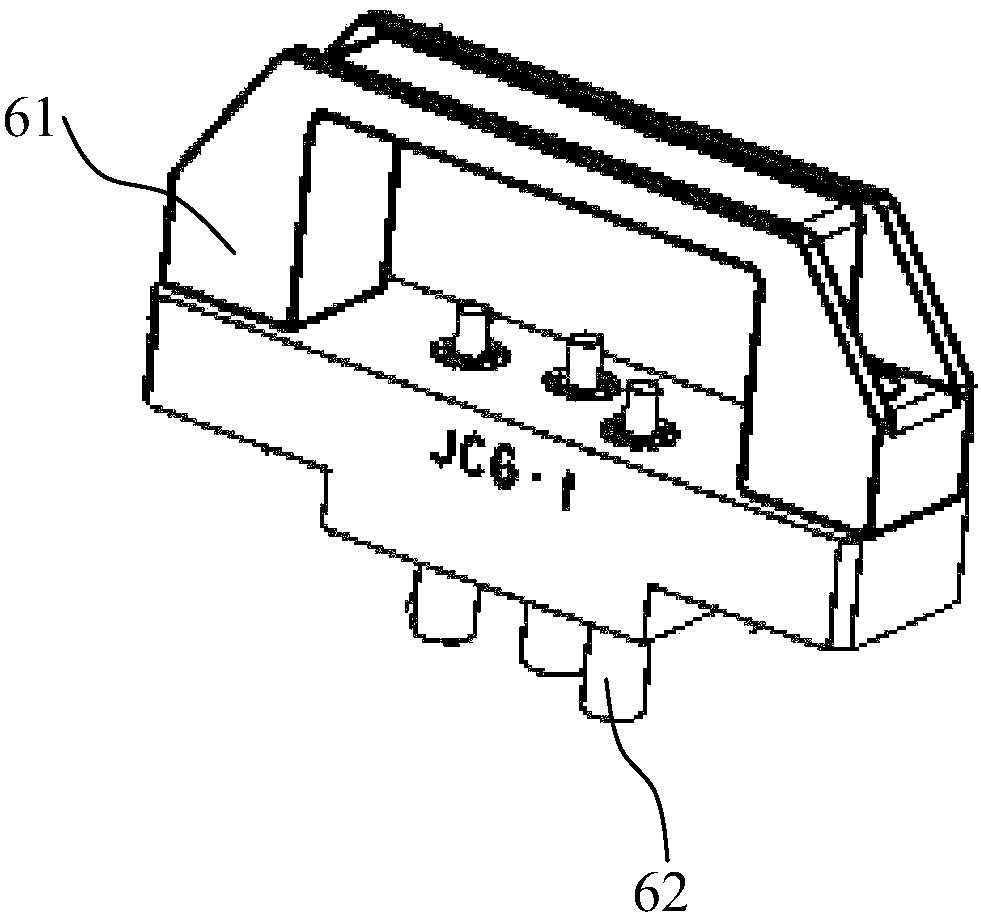

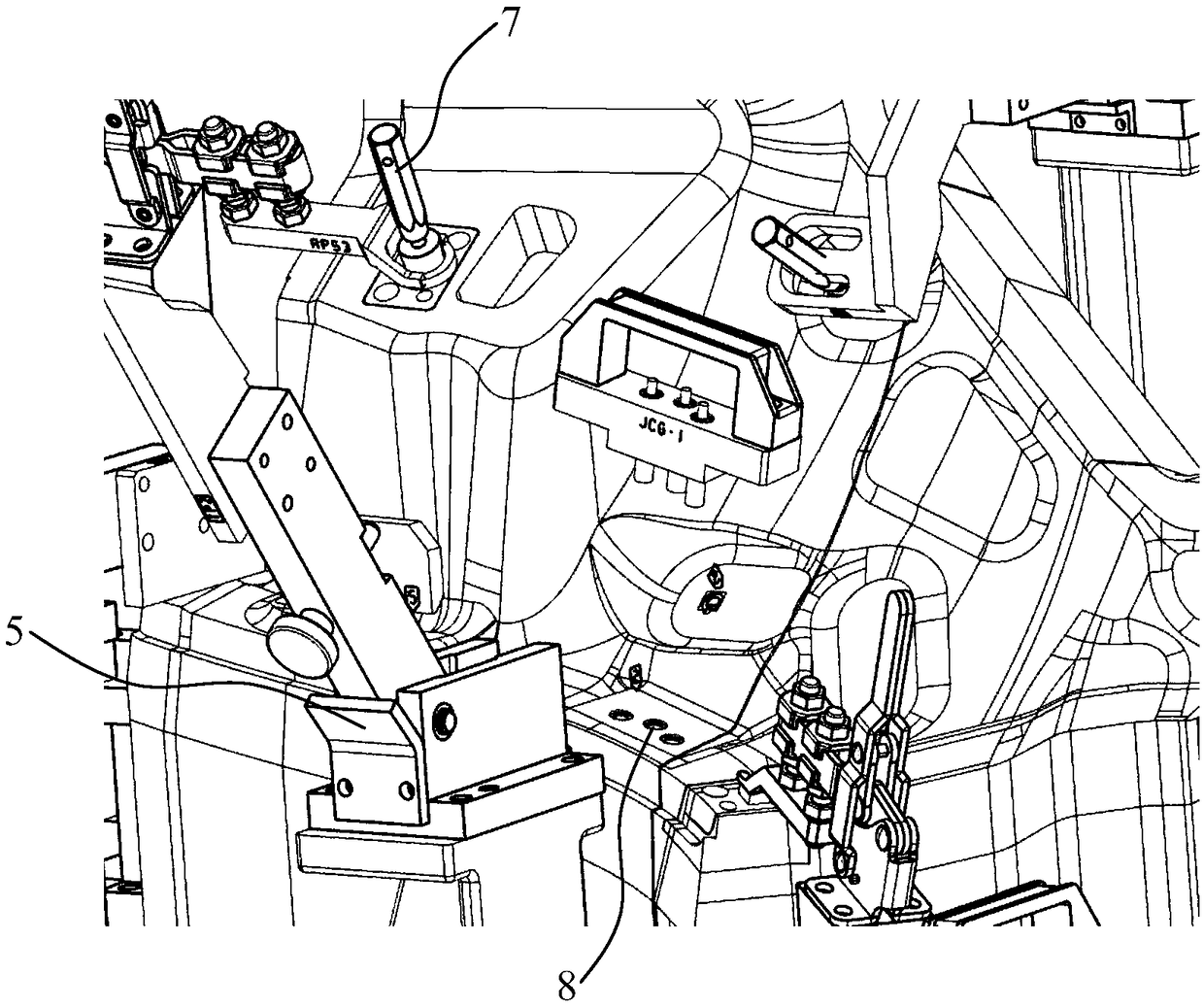

[0024] Embodiment 1: A matching accuracy detector for auto parts, including a coordinate base 1, an analog block seat 2 for placing parts to be tested, a detection rod 3, a clamping mechanism 4, a gap detection mechanism 5, and a through hole position detection mechanism 6 and the go-no-go gauge pin 7, the clamping mechanism 4 and the gap detection mechanism 5 are installed on the coordinate base 1, and the clamp 41 located at the upper end of the clamping mechanism 4 is used to clamp the to-be-placed object on the upper surface of the analog block seat 2. Detection parts, the through hole position detection mechanism 6 further includes a handle base 61 and at least two second pins 62 located on the bottom surface of the handle base 61;

[0025] The lower part of the go-no-go gauge pin 7 is the first pin 71, the middle part of the go-no-go gauge pin 7 is sequentially provided with a go-no-go part 72 and a no-go gauge part 73 from bottom to top, and the upper part of the go-no-g...

Embodiment 2

[0029] Embodiment 2: A matching accuracy detector for auto parts, including a coordinate base 1, an analog block seat 2 for placing parts to be tested, a detection rod 3, a clamping mechanism 4, a gap detection mechanism 5, and a through hole position detection mechanism 6 and the go-no-go gauge pin 7, the clamping mechanism 4 and the gap detection mechanism 5 are installed on the coordinate base 1, and the clamp 41 located at the upper end of the clamping mechanism 4 is used to clamp the to-be-placed object on the upper surface of the analog block seat 2. Detection parts, the through hole position detection mechanism 6 further includes a handle base 61 and at least two second pins 62 located on the bottom surface of the handle base 61;

[0030] The lower part of the go-no-go gauge pin 7 is the first pin 71, the middle part of the go-no-go gauge pin 7 is sequentially provided with a go-no-go part 72 and a no-go gauge part 73 from bottom to top, and the upper part of the go-no-g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com