Double-disc ploughshare comprising innerlying depth guide

A depth control wheel, double disc technology used in ploughs, spaced quantitative seeding machinery, agricultural machinery and implements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

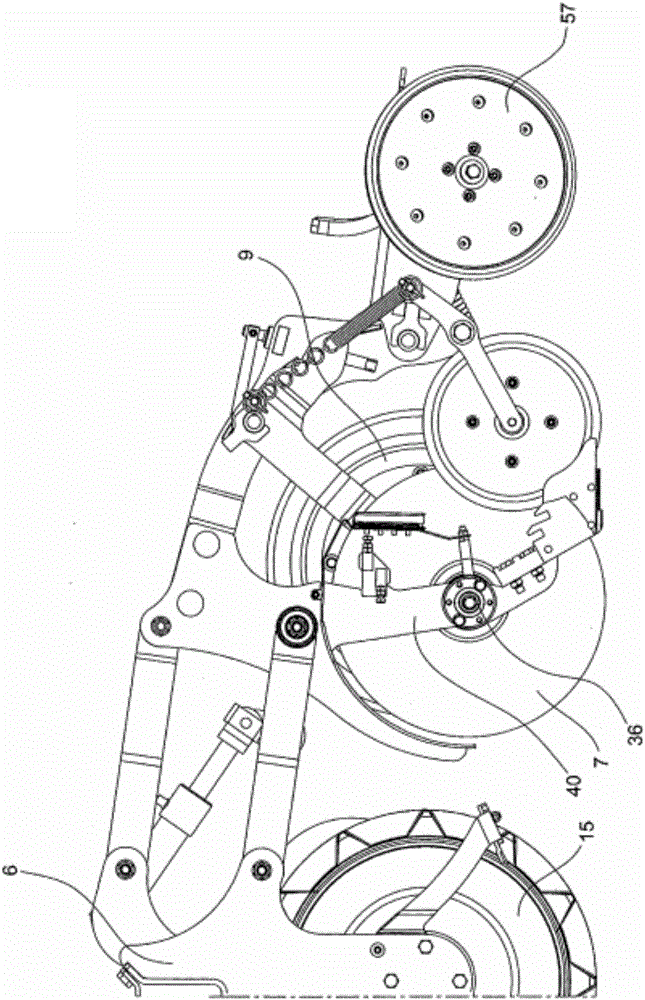

[0030] figure 1 Shown is a side view of the unit which is important for the invention, said unit comprising a sowing coulter supported on a coulter arm 40 and designed as a double disc coulter 7 which rotates about a wheel axle 36 , the unit also includes a depth control wheel 9 arranged flush. In front of the unit comprising the double disc coulters 7, 8 and the depth control wheel 9, it can be seen that the frame 6 is provided with a device 14 designed as a cylinder 15, and behind the unit is a pressure roller 57.

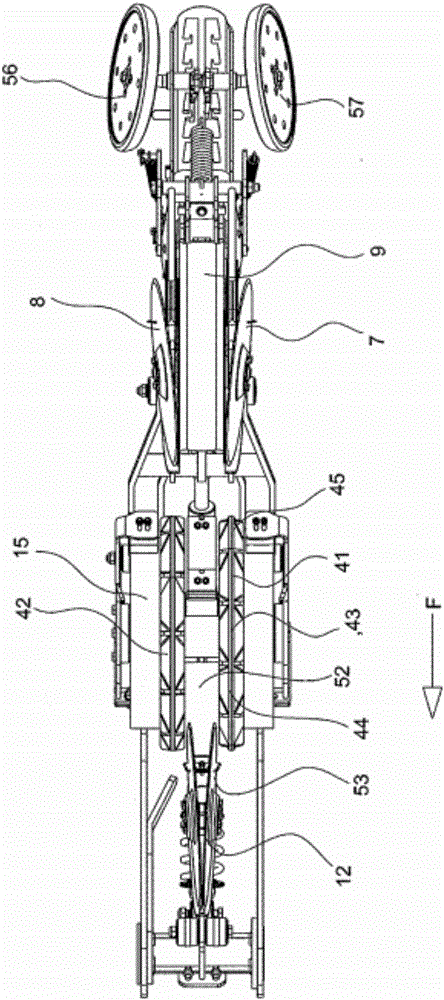

[0031] Such as figure 2 Shown is an overall view from the bottom up, with the direction of travel F indicated, including a view of the transition between the fertilizer coulters 12 and the cylinder 15 . In order to ensure a mutual cleaning effect and avoid soil accumulation as much as possible, the cylinder 15 has a central recess 52 for receiving the rear end 53 of the fertilizer coulter 12 . Rings 41 , 42 are provided on both sides of the recess 52 . Seen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com