A building block for a mechanical construction

A technology of mechanical structure and structure, applied in the direction of mechanical equipment, 3D object support structure, application, etc., can solve the problems such as the limitation of the use of additive manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

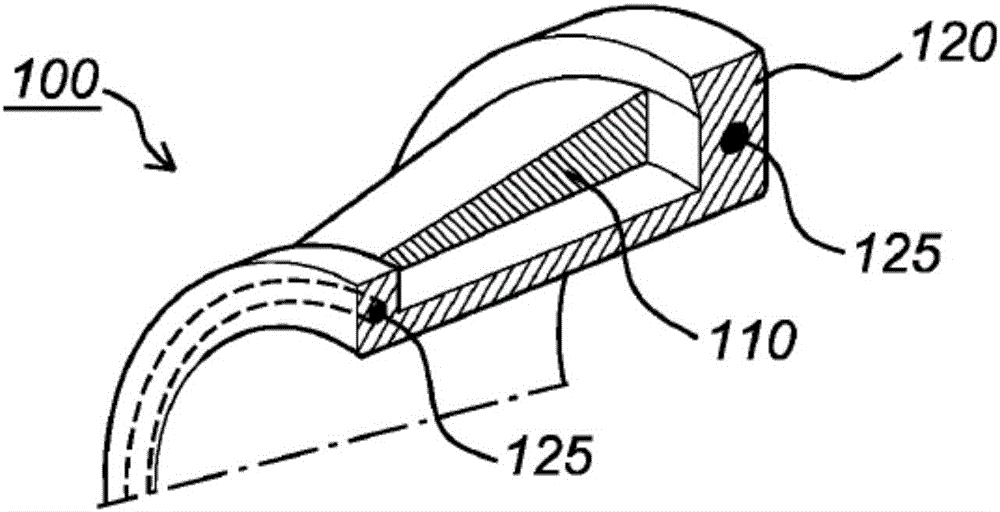

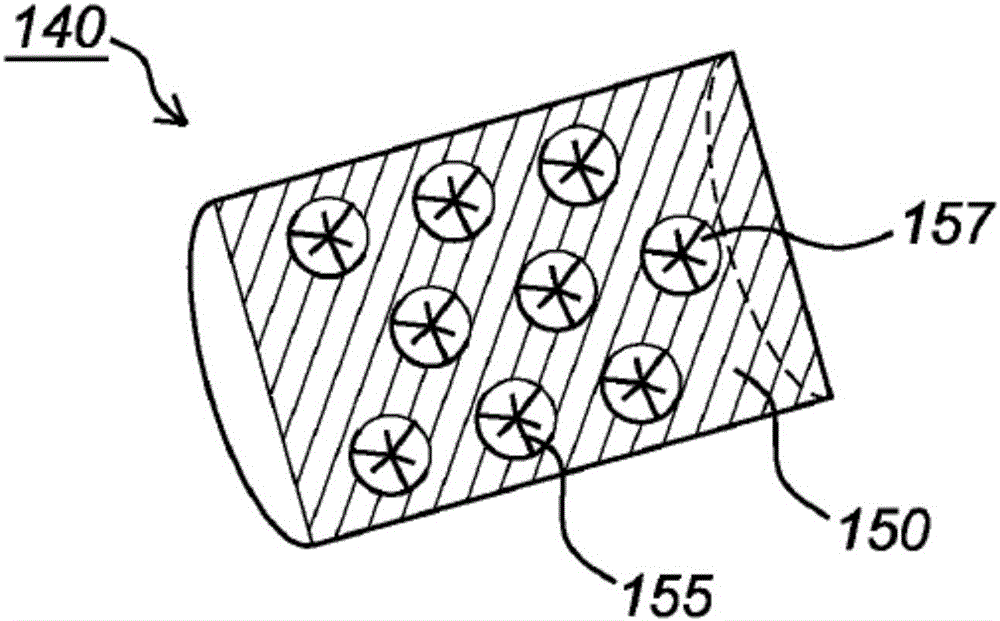

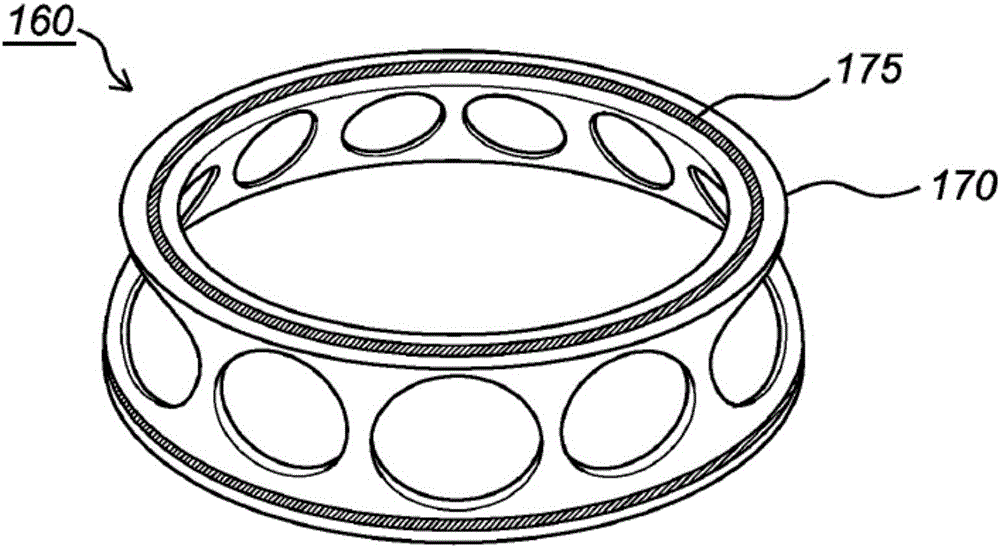

[0039] Figure 1A A bearing 200 according to the present invention is shown (for example, shown in Figure 2A A sectional view of the inner ring 100 of the bearing 200 in . The inner ring 100 is a building block 100 according to the present invention and includes a raceway ring 110 having a raceway surface, and includes a first printing material 120 printed onto the raceway ring 110 . The use of the first printing material 120 provides a very flexible way of manufacturing the shape of the inner ring 100 of the bearing 200, wherein the first printing material 120 can have any desired shape. Using the substantially standardized raceway ring 110 as a starting product, a customized inner ring 100 can be manufactured relatively easily by adding the first printing material 120 . Using this additive manufacturing of adding printing material to a substantially standardized raceway ring 110 ensures a customized inner ring 100 with both high flexibility and high quality. exist Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com