Full-automatic template machine provided with gear

A template machine, fully automatic technology, applied in the direction of cloth feeding mechanism, cloth pressing mechanism, sewing machine components, etc., can solve the problem that it is difficult to ensure the consistent stitch distance of products, and achieve the effect of consistent stitch distance, good product quality and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

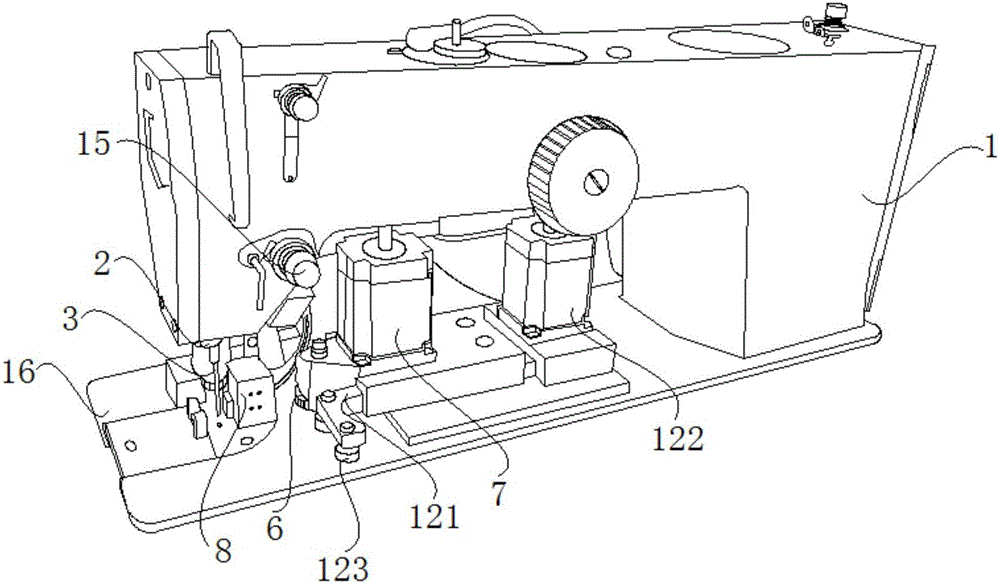

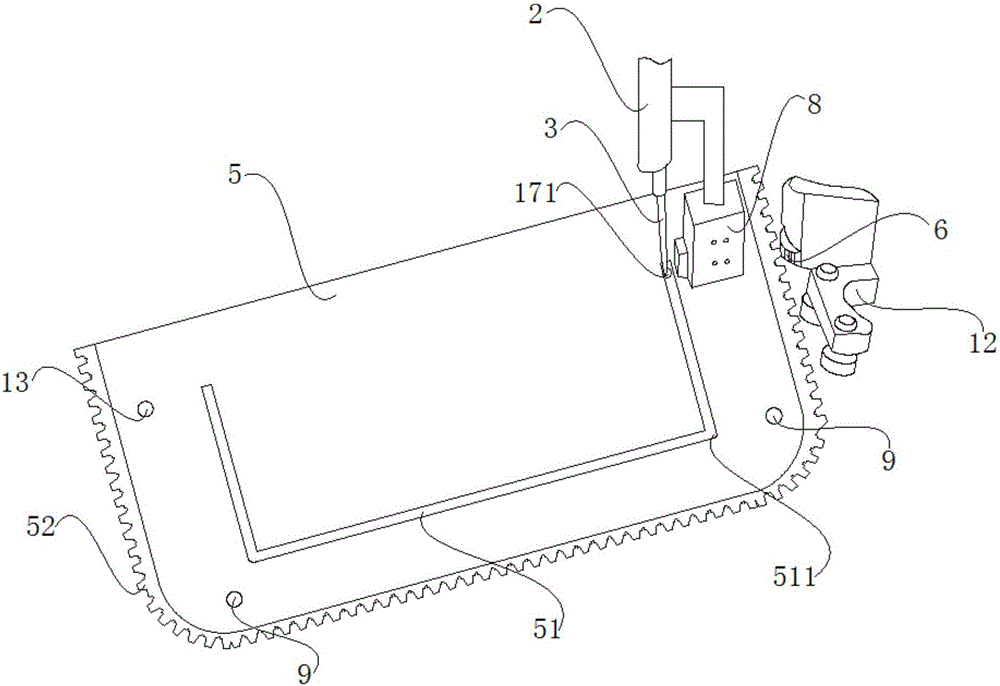

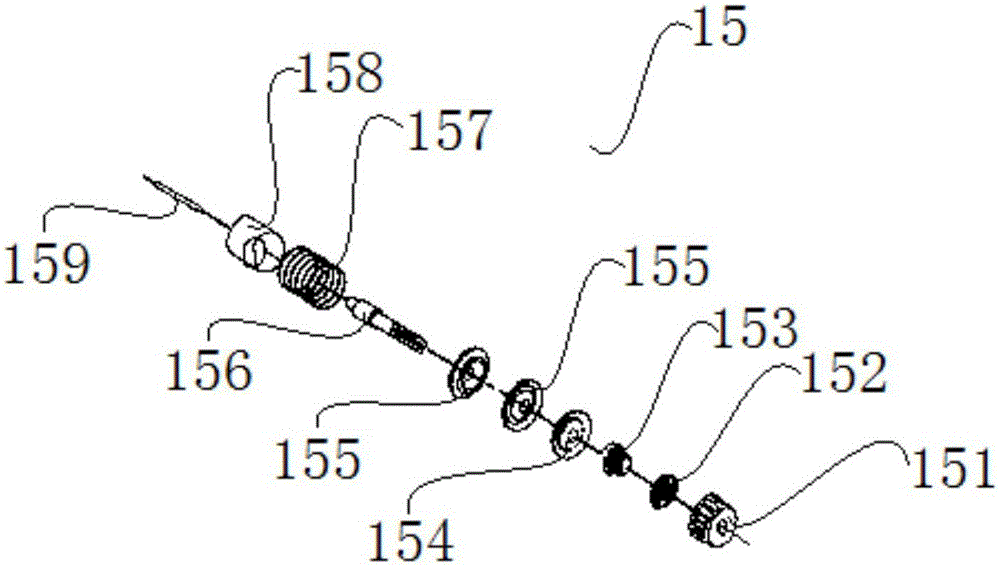

[0021] A fully automatic template machine with gears in the present invention: the second drive unit 7 drives the gear 6 to synchronously drive the template 5 to move at a constant speed, and the template 5 is double-limited by the pinhole seat 171 and the presser foot assembly 8 to prevent the In the process of making clothes, the sewing needle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com