Improved structure of nozzle

A technology of nozzles and spray caps, which is applied in the field of improved structure of nozzles, can solve the problems of poor ability of nozzles to form spray, etc., and achieve the effects of stable and reliable performance, good spraying performance and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

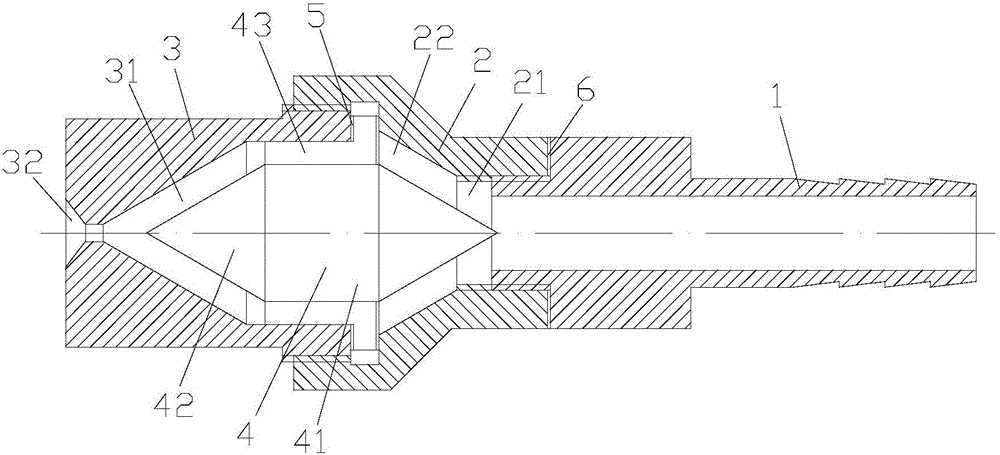

[0013] Such as figure 1 shown. An improved structure of a nozzle, including a pipe joint 1, a spray cap 2, and a nozzle 3, the spray cap 2 has a transverse through cavity, and the through cavity in the spray cap 2 consists of a straight cavity 21 at the rear of the spray cap, a 2. The tapered cavity 22 in the middle of the cone top direction to the right is formed by another straight cavity located in the front part of the spray cap 2, which is expanded in diameter relative to the rear straight cavity, and the diameter of the straight cavity in the front part of the spray cap 2 is larger than that of the middle cone. The diameter of the bottom of the cavity 22 is conical, so that an annular step is formed between the front straight cavity and the middle conical cavity 22 in the spray cap 2. There is a horizontal through cavity in the nozzle 3, and the through cavity in the nozzle 3 is located at the rear of the nozzle 3. The straight cavity of the nozzle 3 is composed of a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com