Positioning push assembly of vertical type channeling machine

A rolling groove machine, vertical technology, applied in the field of vertical rolling groove machine, can solve problems such as affecting the conveying progress and tipping of front-end objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

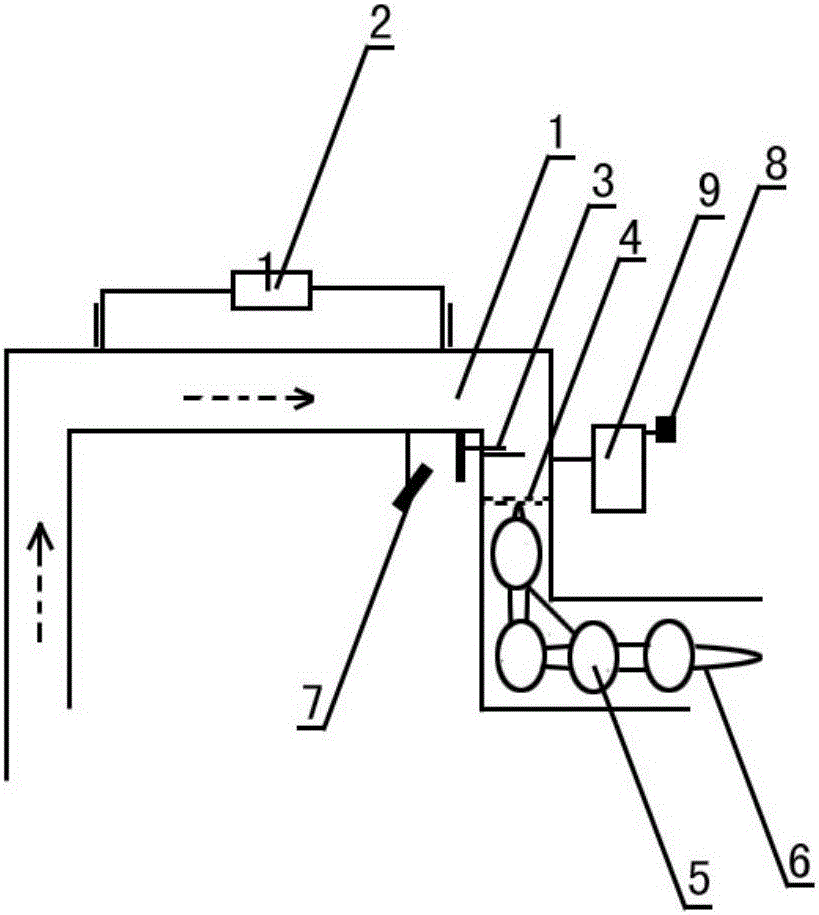

[0012] Embodiment: as shown in the accompanying drawing. The vertical grooving machine positioning and pushing assembly includes a rolling grooving machine operating table (1). The operating table (1) is designed in a similar structure. The No. 1 monitoring device (2) is installed in the middle, and the right side is equipped with a separating part including a dial. moving device (3), segmented layer (4), circular groove (5), crawler belt conveyor (6), No. 2 monitoring device (7) is flush with the segmented layer (4), and is aimed at rolling groove The state is monitored, and at the same time, the grooving objects are pushed into the groove (5) individually and then transported out of the operating table (1).

[0013] The vertical grooving machine locates and pushes the component, and a prompting device (8) is set, and the mode of prompting information is sound or LED sound display.

[0014] Vertical grooving machine positioning and pushing components, the depth of the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com