Mold locking mechanism

A mold clamping and mold technology, applied in the field of mold clamping mechanism, can solve the problems of volume expansion, large axial force of locking teeth, bending, etc., and achieve the effect of reducing instantaneous impulse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

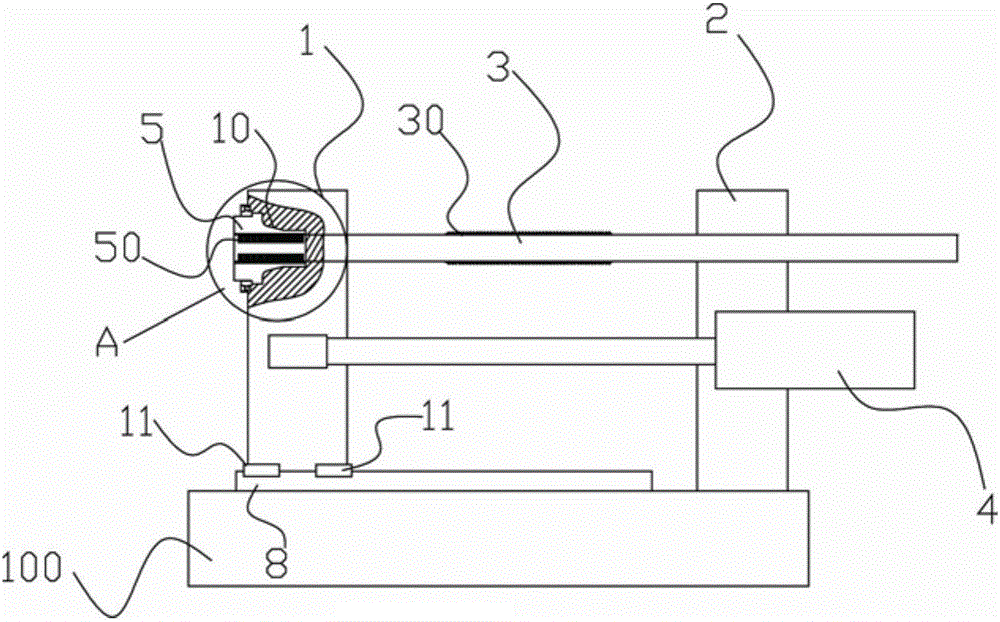

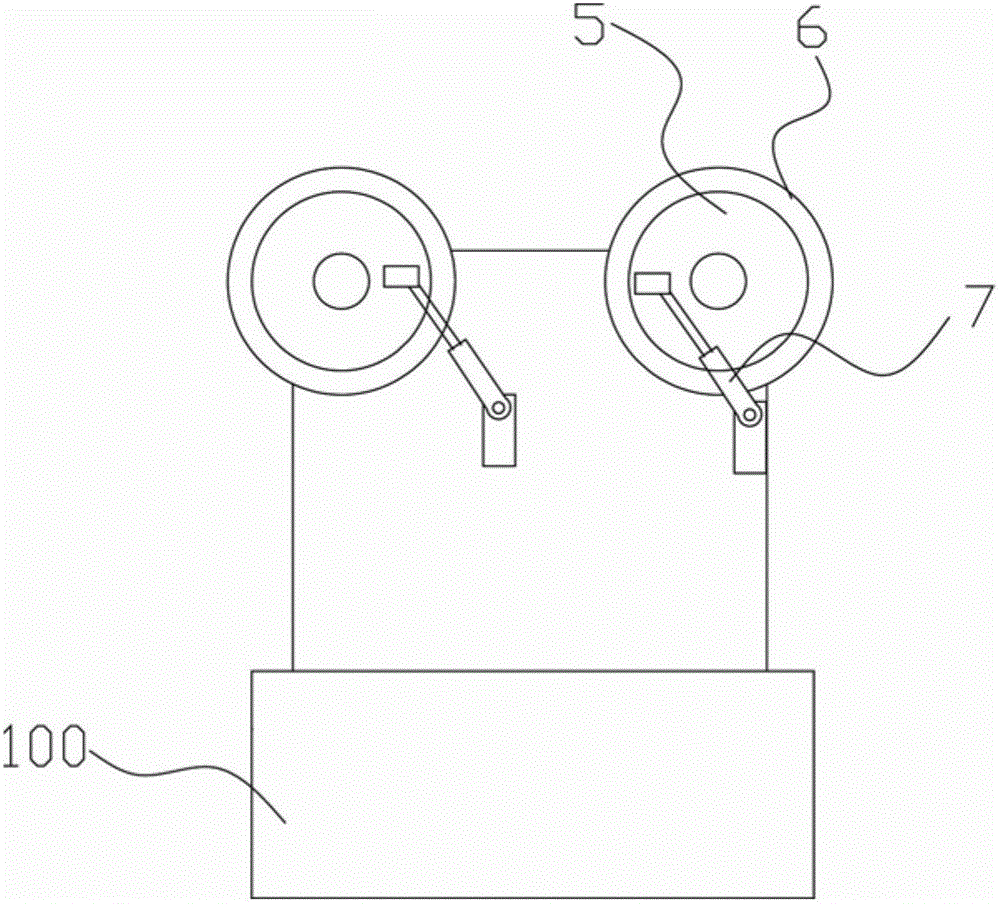

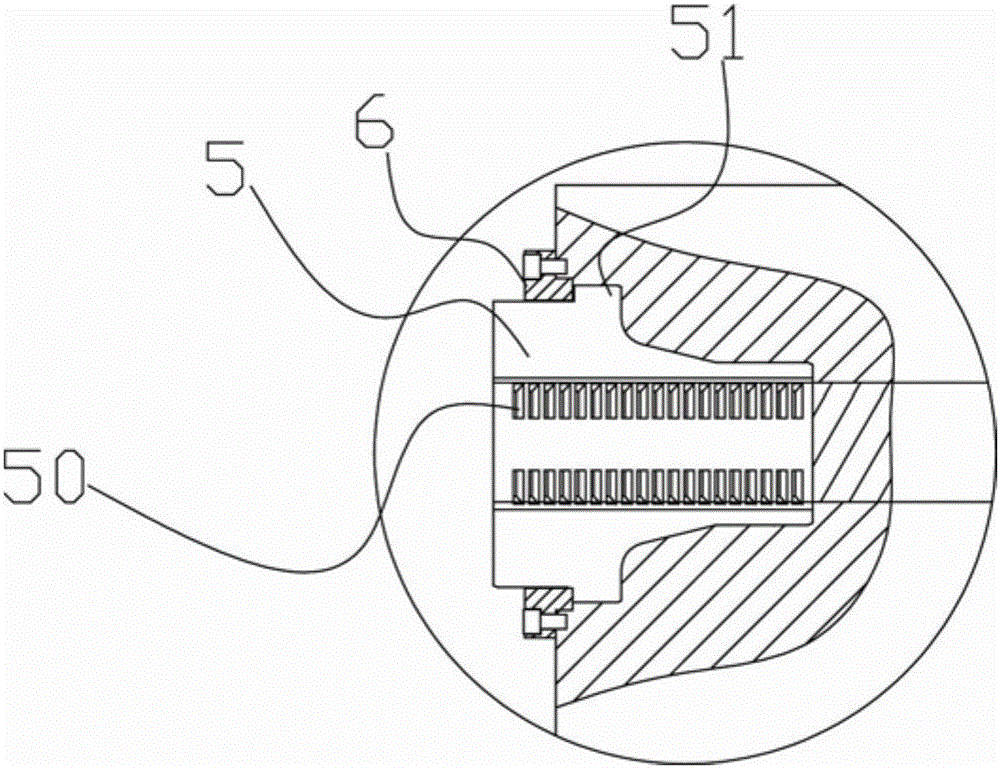

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail: Figure 1-5 As shown, the two-plate clamping mechanism includes a base 100, a movable template 1 and a fixed template 2, and the left side of the base 100 (with attached figure 1 The left side in is defined as the left direction here) with a fixed template 2 erected, and on the base 100 toward the mold opening and closing direction (that is, the horizontal direction) is fixed with a tie rod part 3 for linear guidance, and the tie rod part 3 There are two tie rod parts 3 arranged at intervals, the movable template 1 is arranged on the tie rod parts in a manner that can move along the mold opening and closing direction, and sliding plates are fixedly arranged on both sides of the lower end of the moving film plate 1 . The block 11 is provided with a linear guide rail 8 matching the slider 11 on the base 100 .

[0015] It also includes a mold t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com