Washing machine with heat exchanger

A technology for exchangers and washing machines, which is applied to washing machines with containers, other washing machines, washing devices, etc., can solve the problems of large vibration of the casing, short buffer distance of the sponge layer, noise, etc., so as to improve the utilization rate of heat energy and reduce the instantaneous impulse. , the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

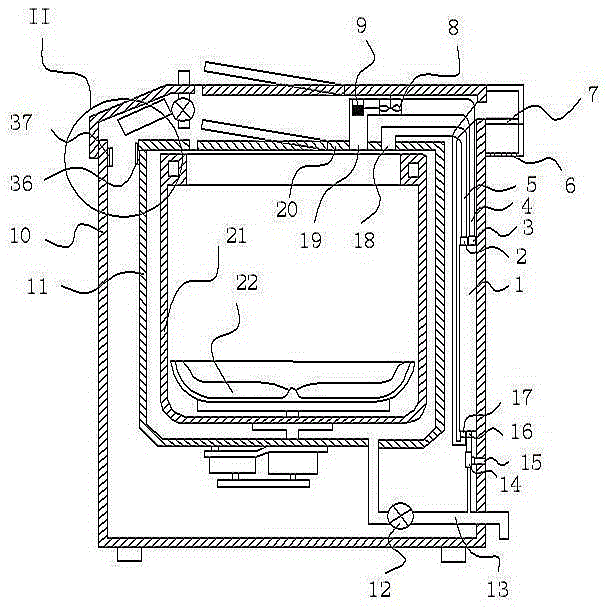

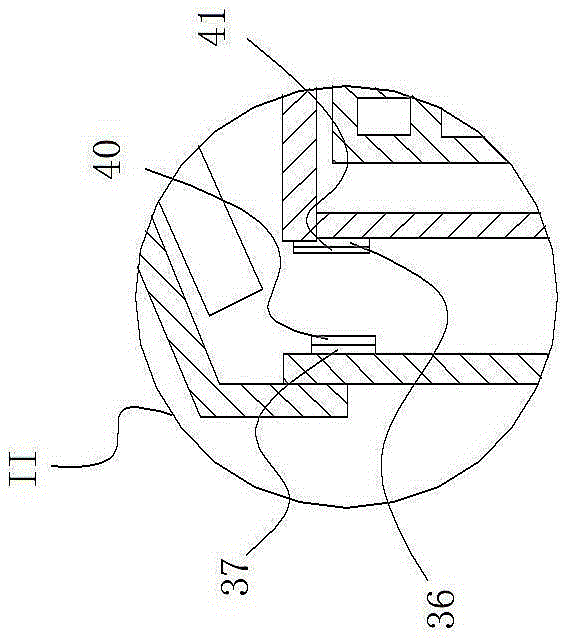

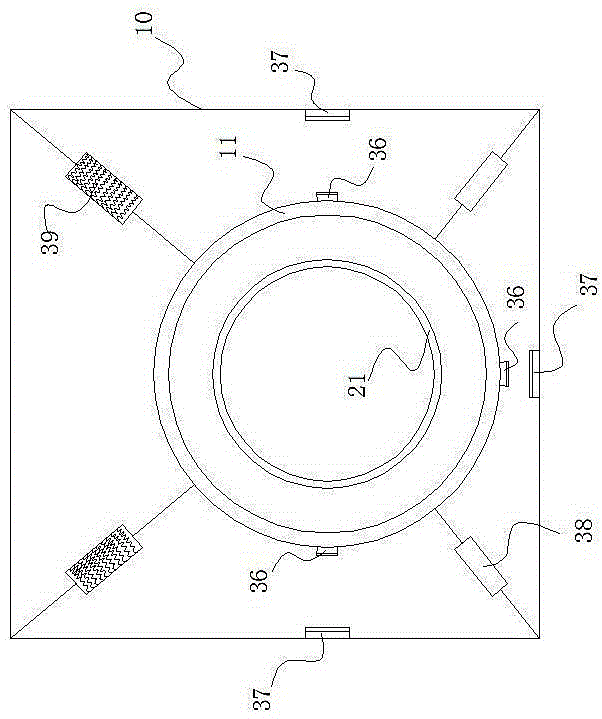

[0021] Such as figure 1 , image 3As shown, the present embodiment comprises casing 10, outer barrel 11, inner barrel 21, pulsator 22, electric heater 9, fan 8, filter 7, and outer barrel 11 is passed through by spring 39, damping shock absorber 38 and suspension rod (not marked) and other suspension components are suspended on the inner side of the casing 10, the inner barrel 21 is rotatably installed on the inner side of the outer barrel 11, and the pulsator 22 is rotatably installed on the inner side bottom of the inner barrel 21; used to drive the inner barrel 21 and the pulsator 22. The rotating rotating shaft (not marked) penetrates the outer tub 11 from the outside of the bottom of the outer tub 11, and is fixedly connected with the inner tub 21 and the pulsator 22 respectively; the drive motor and clutch used to provide power for the rotation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com