Array substrate, production method thereof, touch display panel and display device

An array substrate and touch technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of restricting the ultra-narrow frame of the display panel and the width occupied by the gate drive circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

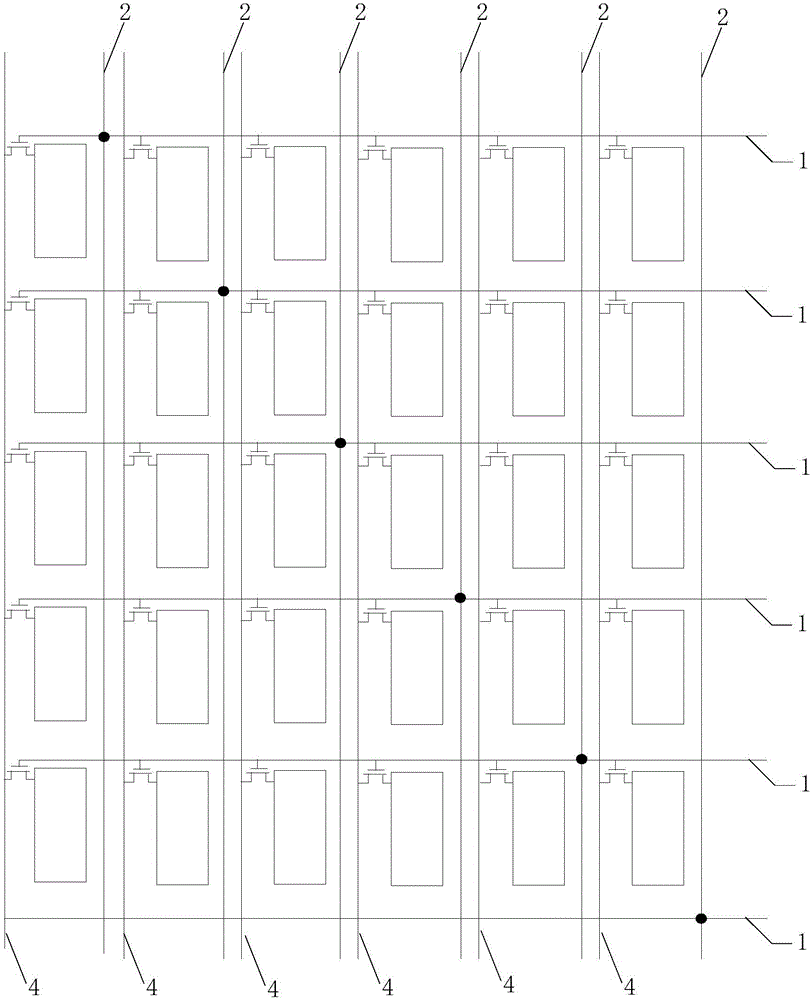

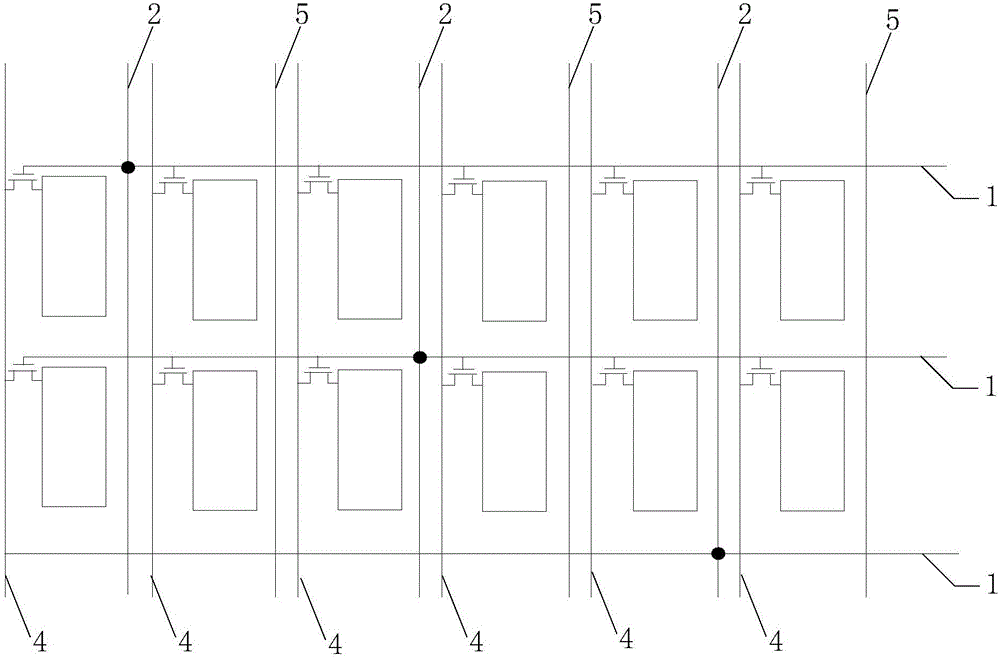

[0032] The specific implementation manners of the array substrate, the manufacturing method thereof, the touch display panel and the display device provided by the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0033] Wherein, the thickness and shape of each film layer in the drawings do not reflect the real proportion of the array substrate, and the purpose is only to illustrate the content of the present invention.

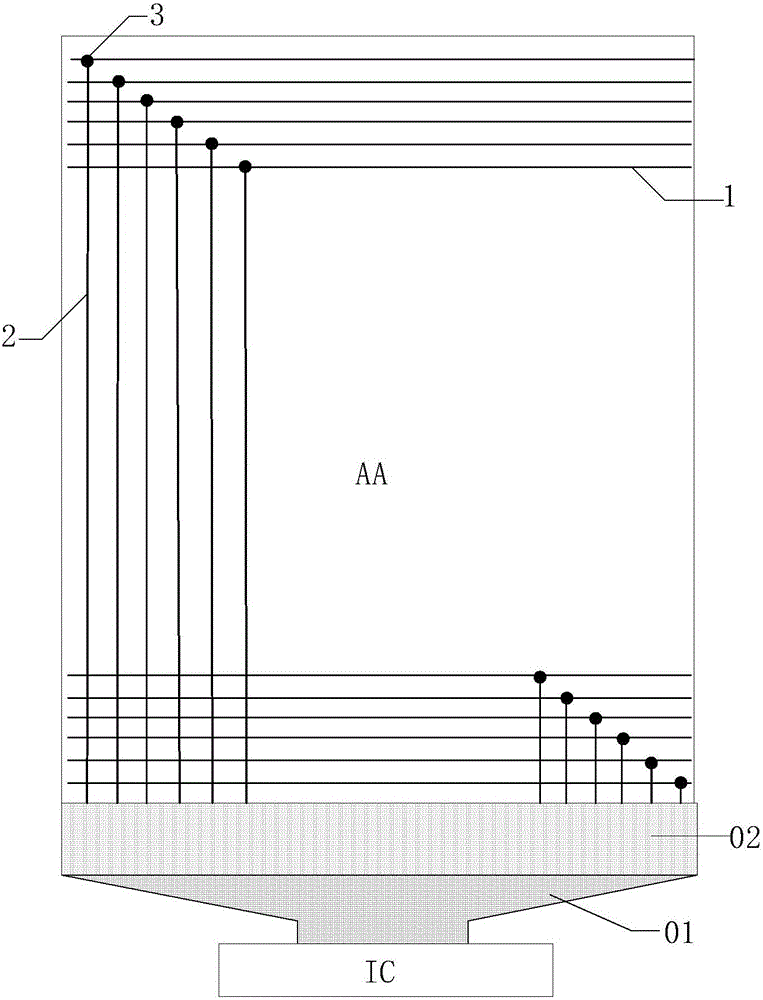

[0034] An embodiment of the present invention provides an array substrate, such as figure 1 As shown, it includes: a base substrate, a plurality of gate lines 1 and a plurality of data lines ( figure 1 not shown in ), and a source drive circuit 01 located in a frame area of the array substrate; each pin of the source drive circuit is directly electrically connected to each data line; it also includes:

[0035] The gate drive circuit 02 located in the same frame area as the source drive cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com