Castor with damping function

A technology of casters and functions, applied in the directions of casters, wheels, transportation and packaging, can solve the problems of equipment damage, casters have no shock absorption function, unfavorable equipment protection, etc., and achieve the effect of simple structure and safety guarantee.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

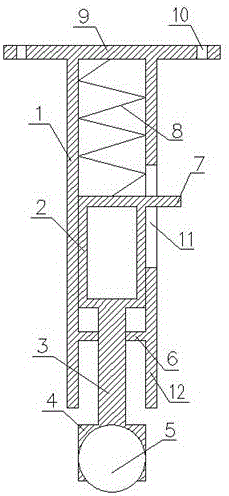

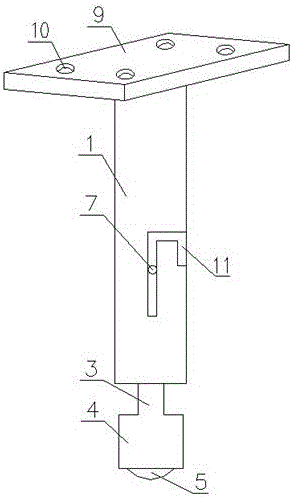

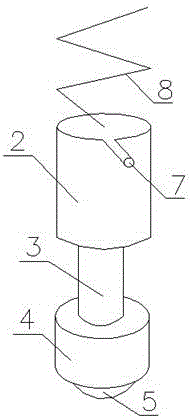

[0023] Casters with shock absorption, such as Figure 1-Figure 3 As shown, it includes an outer cylinder 1 and an inner cylinder 2 , the top of the outer cylinder 1 is fixedly connected with a mounting plate 9 , and the bottom of the mounting plate 9 is fixedly connected with a spring 8 , and the spring 8 is located inside the outer cylinder 1 .

[0024] Such as Figure 1-Figure 3 As shown, the top of the inner cylinder 2 is fixedly connected with the bottom of the spring 8, and the bottom of the inner cylinder 2 is fixedly connected with a connecting rod 3. The connecting rod 3 is made of a metal material with high strength, and is fixed on the connecting rod. The bottom of 3 is fixedly connected with wheel groove 4, and ball 5 is installed in the wheel groove 4.

[0025] The inner cylinder 2 is sleeved in the outer cylinder 1 and can slide freely in one direction in the outer cylinder 1. The user installs the casters on the equipment through the mounting plate. When the equ...

Embodiment 2

[0028] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, further, the bottom of the outer cylinder 1 is provided with a positioning plate 6, and the positioning plate 6 is located below the bottom of the inner cylinder 2, and a hole adapted to the connecting rod 3 is provided on the positioning plate 6, and the connecting rod 3 runs through the positioning plate 6.

[0029] Such as Figure 1-Figure 3 As shown, below the positioning plate 6, an outer cylinder extension 12 is also provided along the length direction of the outer cylinder 1, a positioning pin 7 is arranged on the top of the inner cylinder 2, and a side wall of the outer cylinder 1 is provided A pin groove 11 matched with the positioning pin 7 is arranged.

[0030] The length of the pin groove 11 is greater than the length of the connecting rod 3, so that the positioning pin 7 can drive the inner cylinder 2 to slide on the outer cylinder 1, and the l...

Embodiment 3

[0033] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, further, the mounting plate 9 is provided with mounting holes 10 through which users can mount the casters on various devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com