Manufacturing and use method for screw type domestic crane

A crane and screw technology, applied in the field of tools for home improvement construction, can solve the problems of danger and high labor intensity, and achieve the effect of light weight, small volume and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

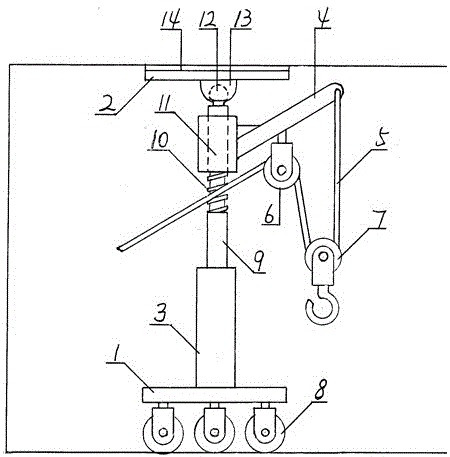

[0013] like figure 1 As shown, a method of manufacturing and using a spiral home improvement crane, the home improvement crane is composed of a chassis 1, an upper plate 2, a hydraulic cylinder 3, a rotating arm 4, a soft rope 5, and fixed and movable pulleys 6 and 7; It is made of steel frame with triangular sides, and universal casters 8 are installed under the triangle of the chassis 1, and the casters 8 are used to carry the weight and load of the whole machine; a hydraulic cylinder 3 (jack) is connected in the middle of the frame of the chassis 1 ), the hydraulic cylinder 3 adopts a base-type one-way hydraulic cylinder, and the base of the hydraulic cylinder 3 is vertically connected with the frame of the chassis 1; a screw rod 10 is connected to the upper end of the ejector rod 9 of the hydraulic cylinder 3, and the screw rod 10 is a circle A section of bolt processed from steel; the bottom of the screw rod 10 and the ejector rod 9 are butt-connected and integrated; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com