Glass lamp shade

A glass lampshade and glass bottom plate technology, which is applied to lampshades, lighting and heating equipment, lighting devices, etc., can solve the problems of time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

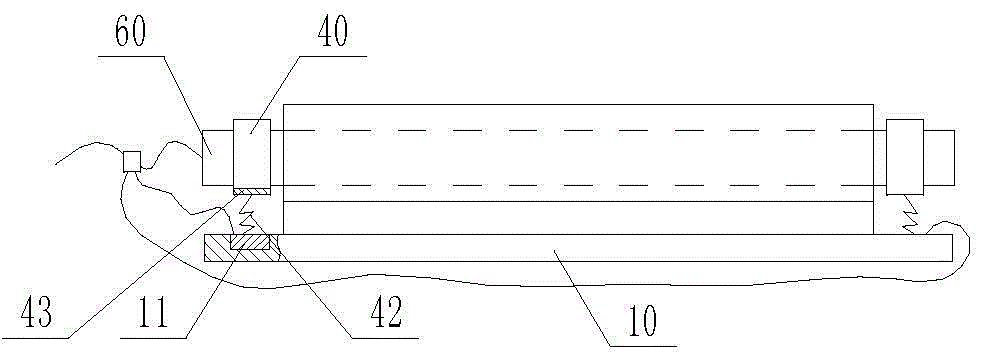

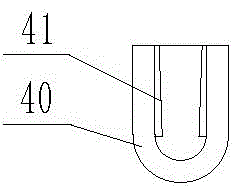

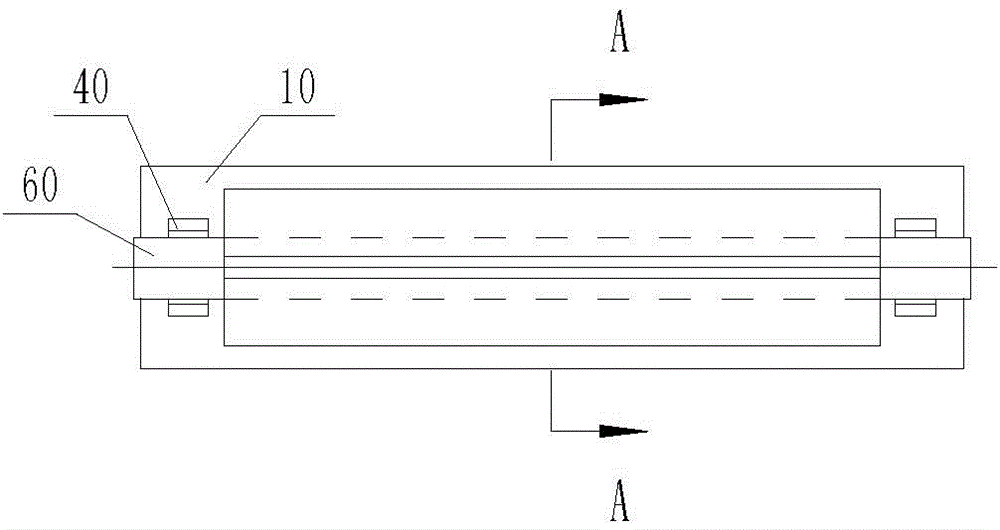

[0016] The reference signs in the accompanying drawings of the description include: glass bottom plate 10, electromagnet block 11, first elastic plate 20, first flexible strip 21, second elastic plate 30, second flexible strip 31, U-shaped clamp 40, wedge Block 41, extension spring 42, permanent magnet block 43, closed cavity 50, lamp tube 60.

[0017] The embodiment is basically as figure 1 and Figure 4 Shown: a glass lampshade, including a glass bottom plate 10 , a first elastic plate 20 and a second elastic plate 30 . The first elastic plate 20 is provided with a first arc-shaped groove, the second elastic plate 30 is provided with a second arc-shaped groove, the first arc-shaped groove and the second arc-shaped groove are oppositely arranged, the first elastic plate 20, the second The elastic plate 30 and the glass bottom plate 10 form a closed cavity 50 for accom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com